Automatic cyclic shakeout wear resistance testing device

A wear-resistant testing and testing device technology, applied in measuring devices, testing wear resistance, instruments, etc., can solve the problems that the experimental results cannot meet the standard requirements, cannot be fixed, and the flow rate of the conduit cannot be controlled, and achieves objective experimental results. The effect of realizing full automation and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

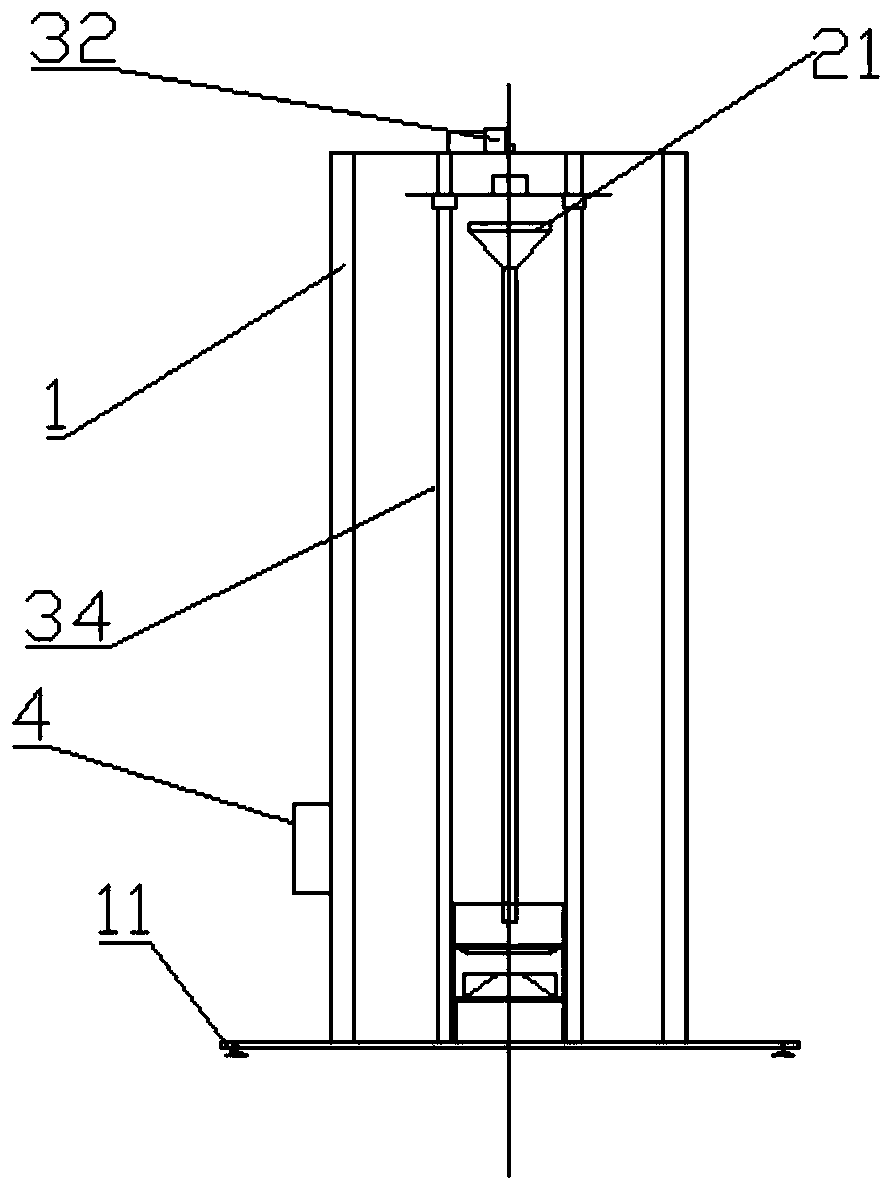

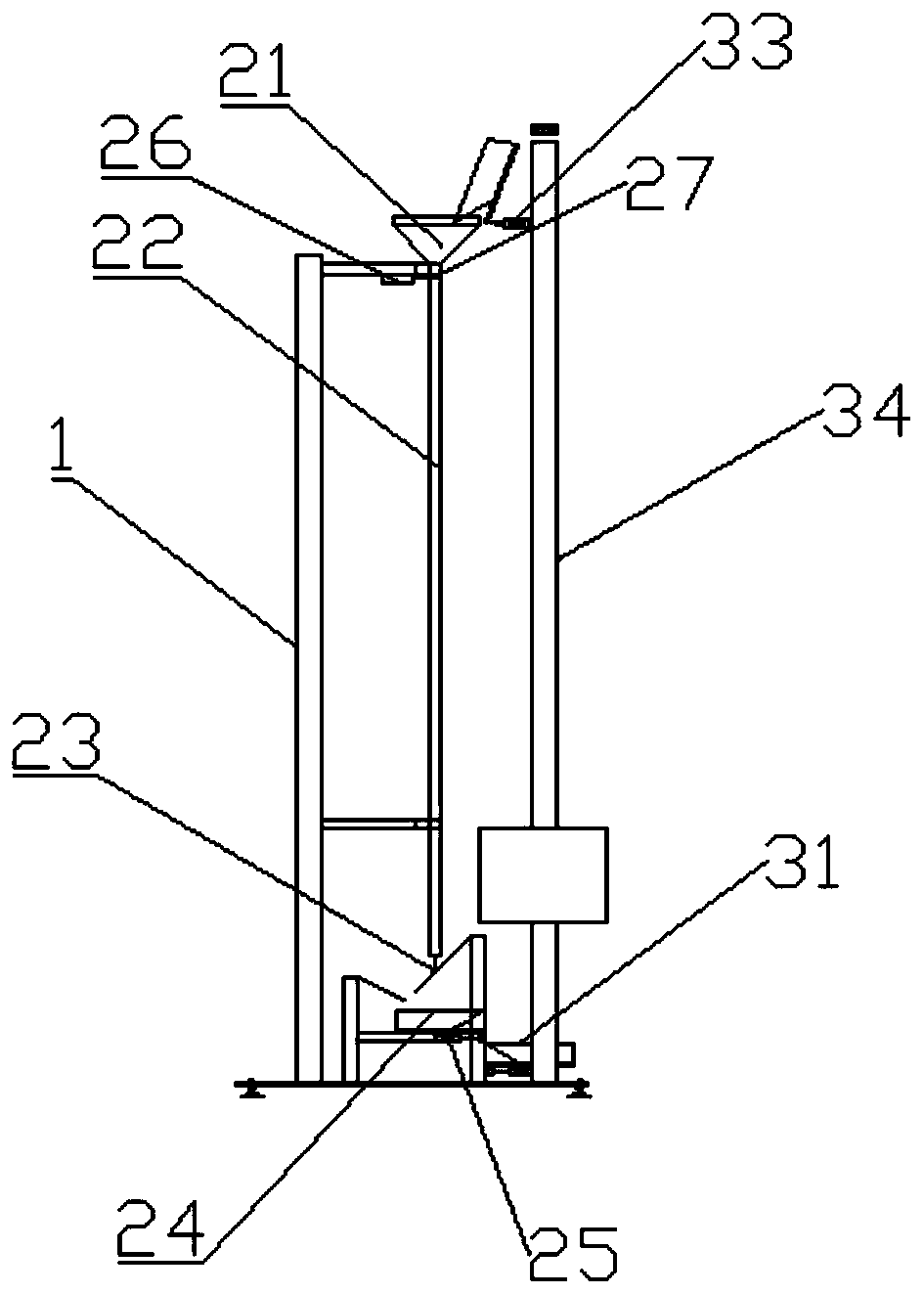

[0027] see Figure 1-Figure 2 As shown, the present invention discloses an automatic cyclic sand shakeout wear resistance test device, which includes a square frame-shaped integral support 2, a sand shakeout mechanism, a transmission mechanism and a control system 4;

[0028] The bottom of the integral support 1 is provided with adjustable feet 11; adjusting the height of the feet can adjust the height and horizontal balance of the whole device.

[0029] The sand shakeout mechanism is fixed on one side of the overall support 1, and from top to bottom are the funnel 21, the conduit 22, the test plate fixture 23, the sandbox 24, and the sandbox cylinder 25. The test plate fixture 23 is an inclined structure And the lower end falls above the sandbox 24; the conduit 22 is made of metal, with an inner diameter of 18.97-19.13mm and an outer diameter of 21.97-22.47mm. The minimum vertical distance from the conduit 22 to the test plate fixture is 25.4 mm; it meets the requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com