Sample purification and concentration device

A concentration device and sample technology, which is applied in the direction of measurement device, test sample preparation, sampling, etc., can solve the problems of difficult processing, long filtration time, easy to break membrane, etc., and reduce the probability of concentration polarization and purity And the effect of high recovery efficiency and increased membrane filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

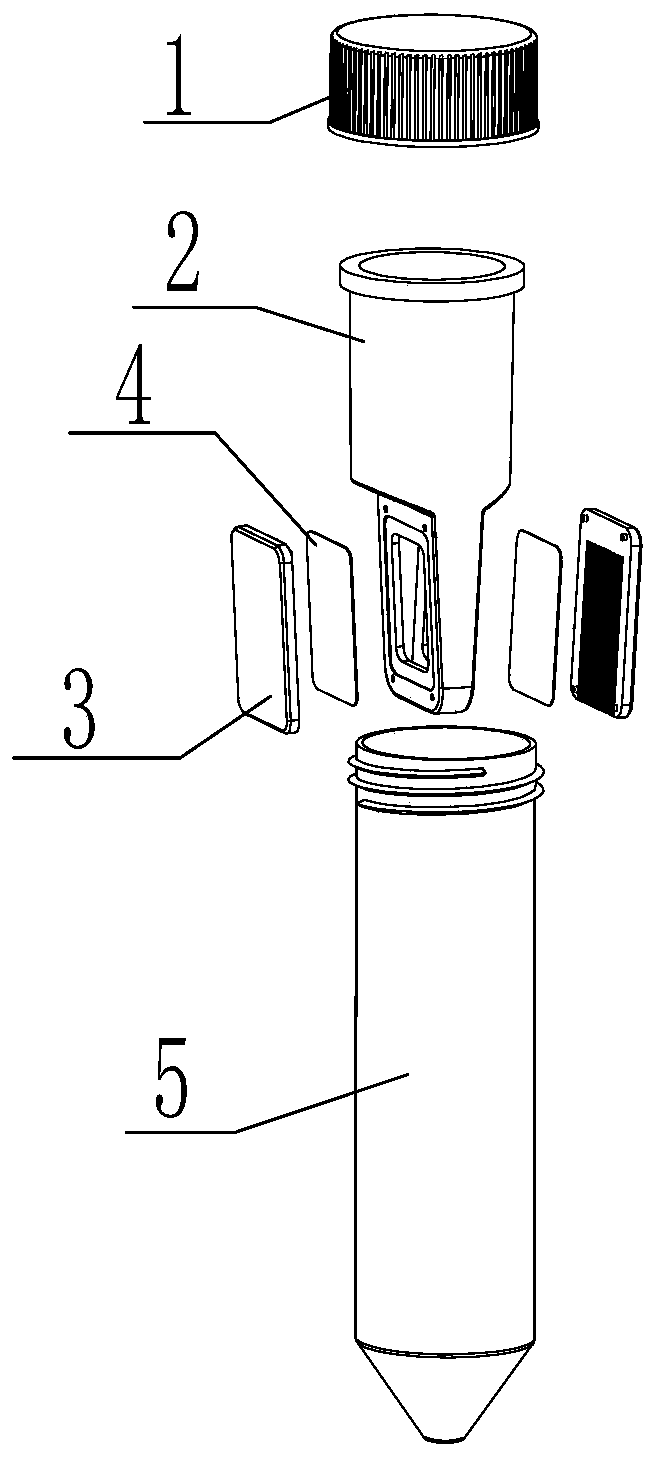

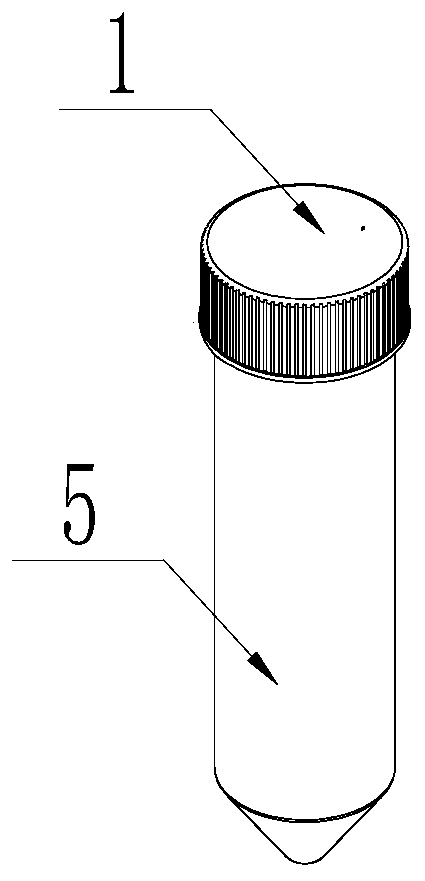

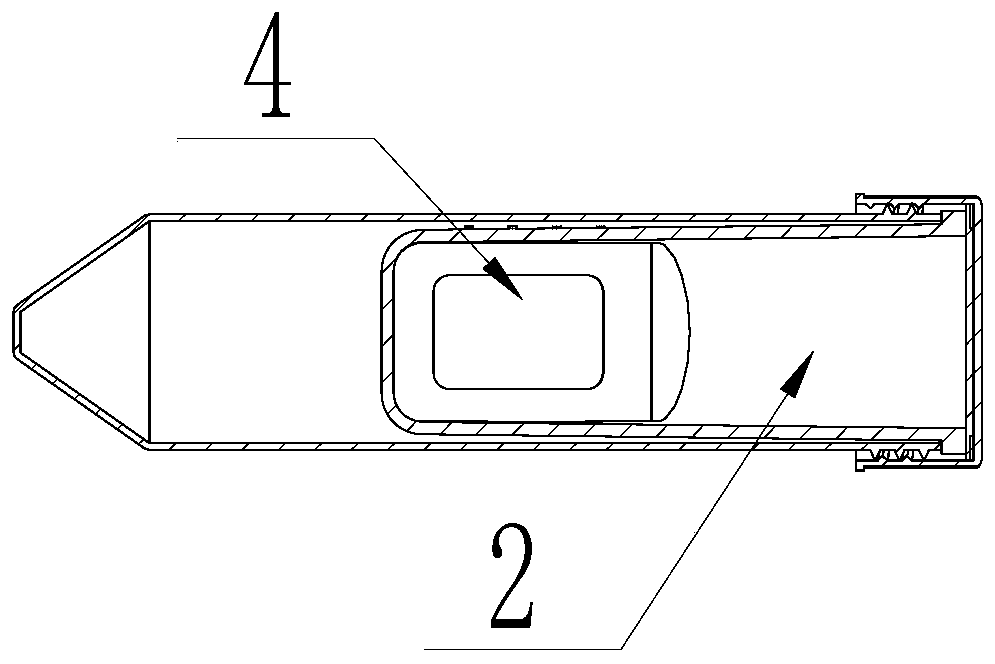

[0034] Such as Figure 1-5 As described above, the present invention provides a sample purification and concentration device, including an end cap 1, a trough tube 2, a filter membrane support 3, a filter membrane 4, and a centrifuge tube 5; the inside of the filter membrane support 3 has a feed liquid flow channel 6, The outlet 7 of the flow channel leads directly to the bottom, and the trough tube 2 has a sample holding cavity, and the side of the trough tube 1 has a liquid outlet connected to the sample holding cavity, and the filter membrane 4 is fixed on the trough tube first. 1 and cover the liquid outlet, and then the filter membrane support 3 is attached to the filter membrane 4 and fixed vertically or obliquely on the trough tube 2, and then inserted into the centrifuge tube 5 together with the trough tube 2, and then passed The end cap 1 is tightly closed, and the sample holding chamber, the filter membrane 4, the feed liquid flow channel and the centrifuge tube 5 ar...

Embodiment 2

[0054] Using the same test procedure as in Example 1, the difference is that a smaller device of the present invention is used, and the initial volume is changed to 5ml.

[0055] Table 3 Comparison test of 5ml centrifugal ultrafiltration device for the removal of sodium chloride and the recovery of protein solution

[0056]

[0057] Table 3 shows that, by comparison, it is found that the device of the present invention does not change the protein recovery rate and desalination rate with the change of the specification volume, and it also has better performance than similar commercially available products, and is also better than the performance of the patent CN206924902U applied for earlier , at the same time, the desalination rate does not depend on the concentration and volume of the sample. Desalting by ultrafiltration does not change the composition of the buffer, and repeated dilution and filtration. This process is called equal-volume ultrafiltration, which is repeated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com