Phosphorus and nitrogen oligomer flame retardant and preparation method thereof

A flame retardant and oligomer technology, applied in the field of phosphorus nitrogen oligomer flame retardant and its preparation, can solve the problems of inability to meet the requirements of processing temperature, large impact on material mechanical properties, poor thermal stability, etc. Commercial value and market prospects, good thermal stability, easy post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Mix 0.06 mol piperazine and 0.15 mol triethylamine dissolved in 156 g of acetonitrile, heat to reflux temperature, and add 0.066 mol phenylphosphonic dichloride diluted with solvent drop by drop. After the dropwise addition is completed within 2 hours, the Keep the reaction at the reflux temperature of 60-80°C for 6-8 hours; after the reaction, distill the solvent under reduced pressure, dissolve the residue in ethanol, filter to remove triethylamine hydrochloride, pour the filtrate into a large amount of ether to precipitate a brown precipitate, filter, Washing with water several times, and vacuum-drying at 80° C. to obtain the phosphorus nitrogen oligomer flame retardant phenylphosphonopiperazine, the yield is 50.0%.

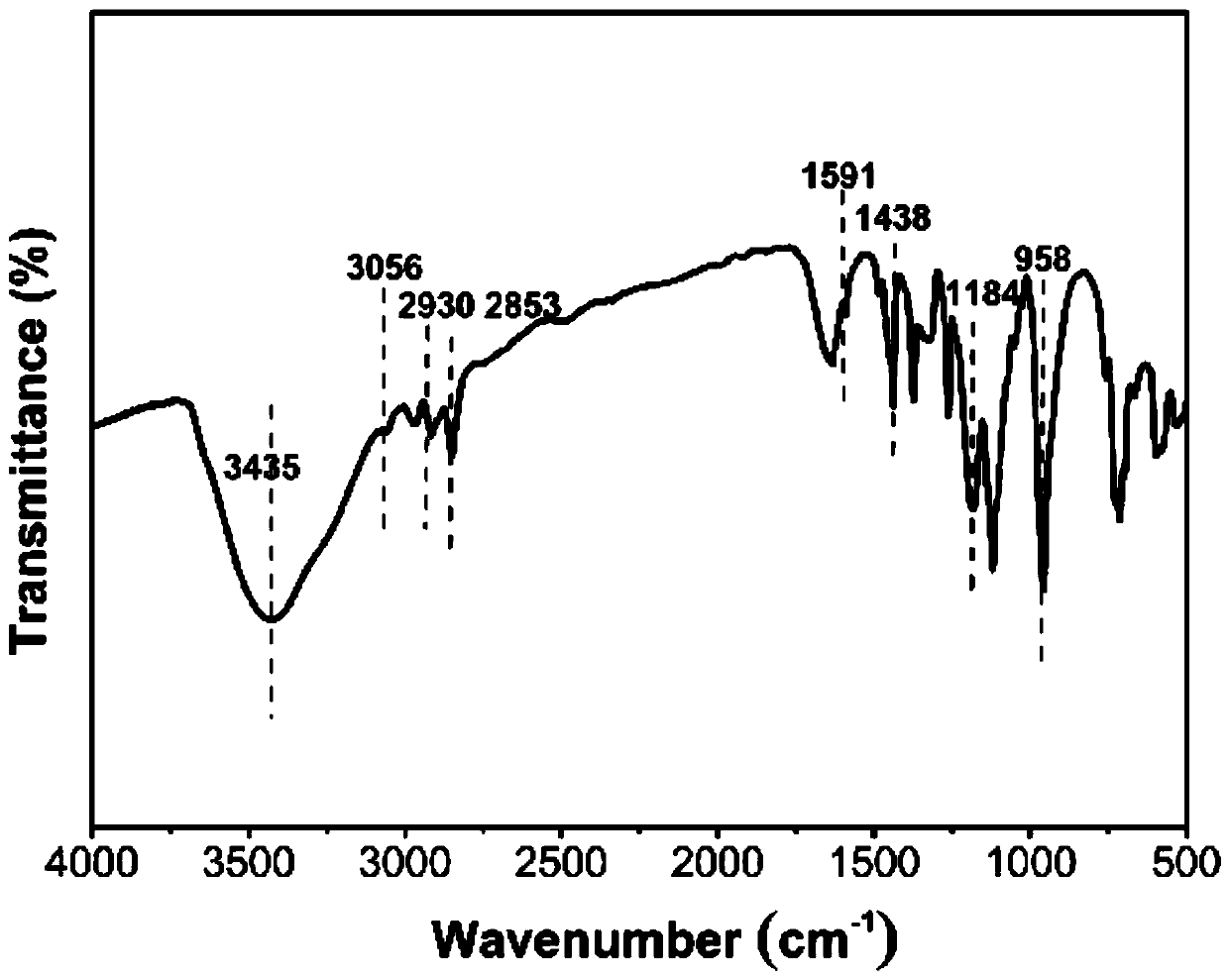

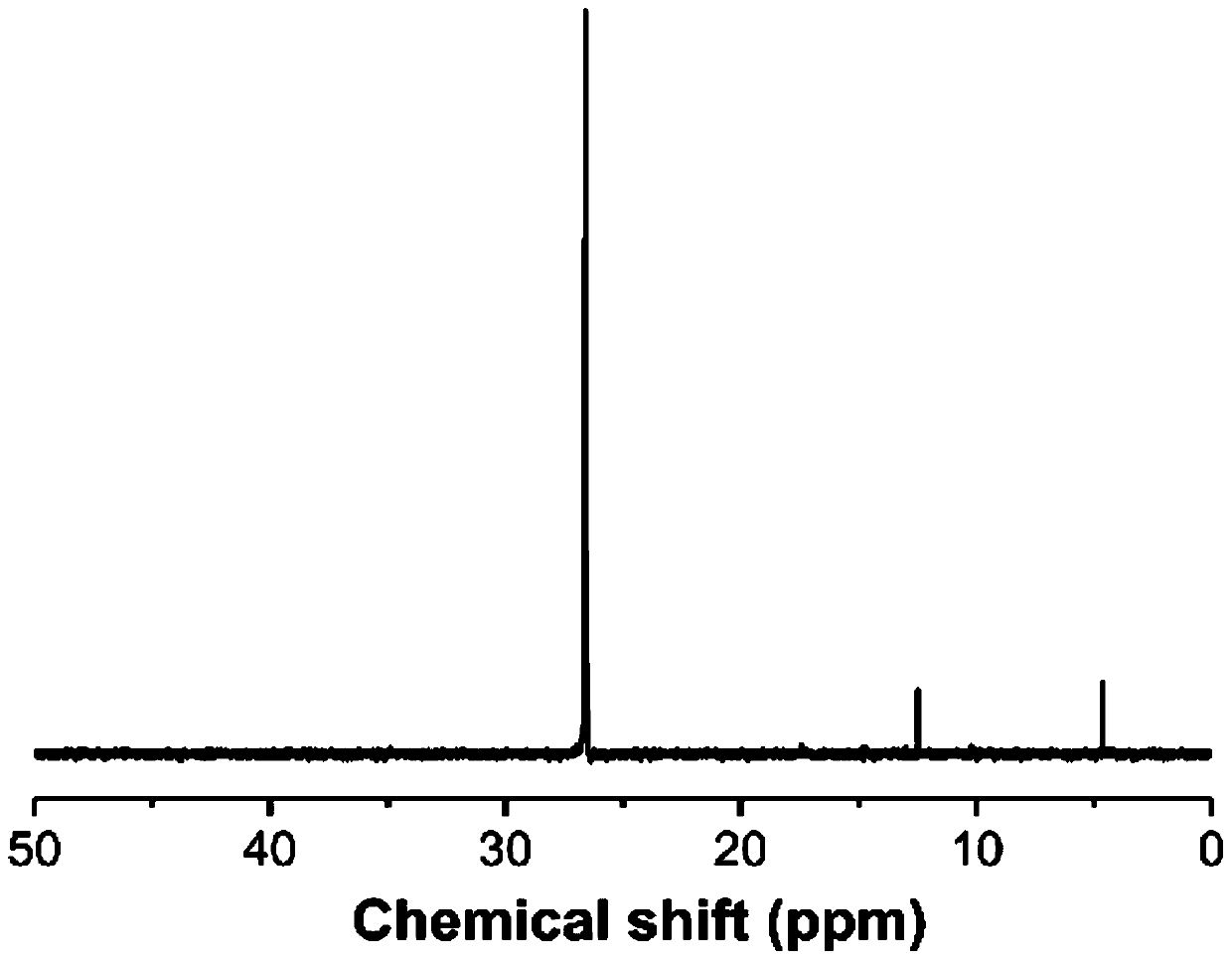

[0036] The infrared spectrogram of the prepared phosphorus nitrogen oligomer flame retardant, 1 H NMR and 31 P-NMR see respectively Figure 1-Figure 3 .

[0037] Phenylphosphonopiperazine test analysis results are as follows:

[0038] FTIR (KBr, cm-...

Embodiment 2

[0042] Mix 0.06mol 1,4-butanediamine and 0.15mol triethylamine dissolved in 156g acetonitrile, heat to reflux temperature, add 0.066mol phenylphosphonic acid dichloride diluted with solvent drop by drop, drop within 2h After the addition is complete, keep the reaction at the reflux temperature of 60-80°C for 6-8h; after the reaction, distill the solvent off under reduced pressure, dissolve the residue in ethanol, filter to remove triethylamine hydrochloride, pour the filtrate into a large amount of ether to precipitate The brown precipitate was filtered, washed with water several times, and vacuum-dried at 80° C. to obtain a phosphorus nitrogen oligomer flame retardant phenylphosphonobutylene diamine with a yield of 2.5%.

Embodiment 3

[0044] Mix 0.06mol 1,6-hexanediamine and 0.15mol triethylamine dissolved in 156g acetonitrile, heat to reflux temperature, add 0.066mol phenylphosphonic dichloride diluted with solvent drop by drop, drop within 2h After the addition is complete, keep the reaction at the reflux temperature of 60-80°C for 6-8h; after the reaction, distill the solvent off under reduced pressure, dissolve the residue in ethanol, filter to remove triethylamine hydrochloride, pour the filtrate into a large amount of ether to precipitate The brown precipitate was filtered, washed with water several times, and vacuum-dried at 80° C. to obtain a phosphorus nitrogen oligomer flame retardant phenylphosphonamide hexamethylenediamine, with a yield of 33.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com