A multi-helical channel annular superconducting magnetic fluid propeller

A spiral channel and superconducting magnetic technology, which is applied in the direction of ship propulsion, propulsion components, ship components, etc., can solve the problems of complex structure, large local resistance loss in the flow area of deflector and rectifier, unfavorable coordinated arrangement of propeller and hull, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

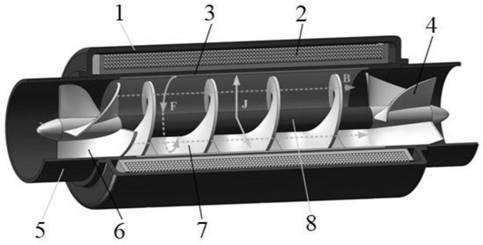

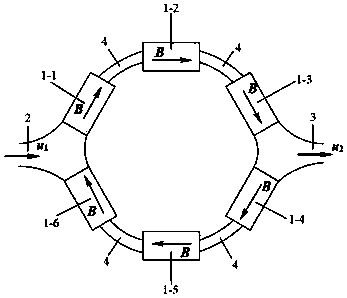

[0025] Such as Figure 4 Shown, the specific embodiment of the present invention one is uniformly distributed along the longitudinal monolayer of underwater vehicle 4, by 10 tangentially entering-tangentially going out the superconducting ferrofluid propulsion unit 1 of 10 single helical channels and 10 water inlet pipes 2 and 10 outlet pipes are composed of 3. 10 single-helical superconducting magnetic fluid propulsion units 1 with tangential entry and tangential exit are evenly distributed along the circumferential direction of the outer surface of the cylindrical underwater vehicle shell 4, and 10 water inlet pipes 2 and 10 water outlet pipes 3 are connected with The longitudinal direction of the cylindrical underwater vehicle housing 4 is parallel to the central axis OO. The inlet of the water inlet pipe 2 gradually expands, and the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com