Manufacturing process method of double-ridge sealed horn antenna

A horn antenna and manufacturing process technology, applied in the microwave field, can solve the problems of uneconomical benefits, poor product quality consistency, poor product quality consistency, etc., and achieve significant advantages in production efficiency and manufacturing cost, product quality consistency and Stable and consistent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

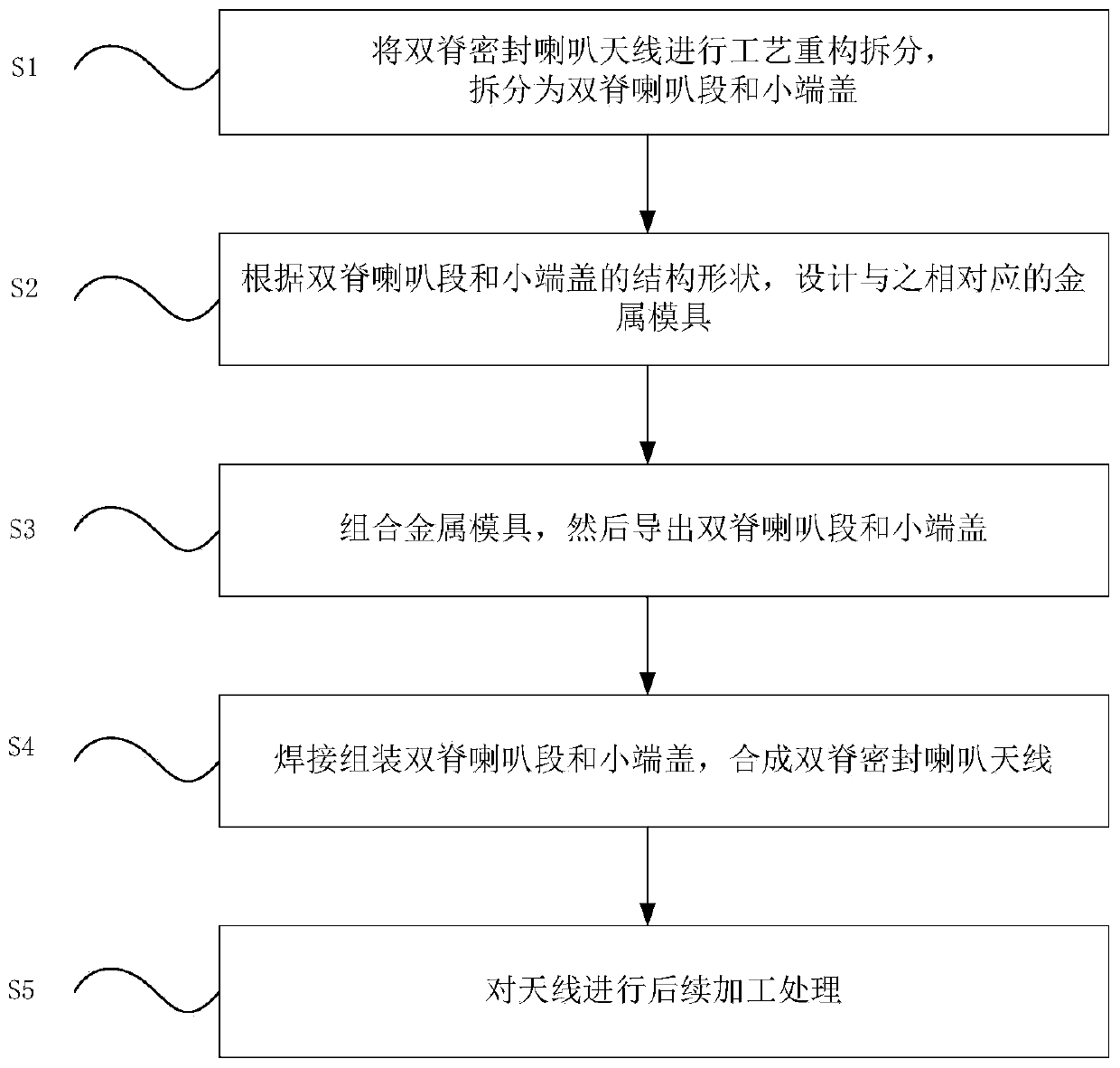

[0030] Such as figure 1 Shown, a kind of manufacturing process method of double ridge sealed horn antenna, comprises:

[0031] Step 1: Carry out process reconstruction and disassembly of the double-ridge sealed horn antenna, and split it into two parts, that is, the small end cap of the end face and the double-ridge horn section.

[0032] Step 2: According to the shape and structure of the double-ridge horn section and the small end cap, respectively design metal molds corresponding to the two.

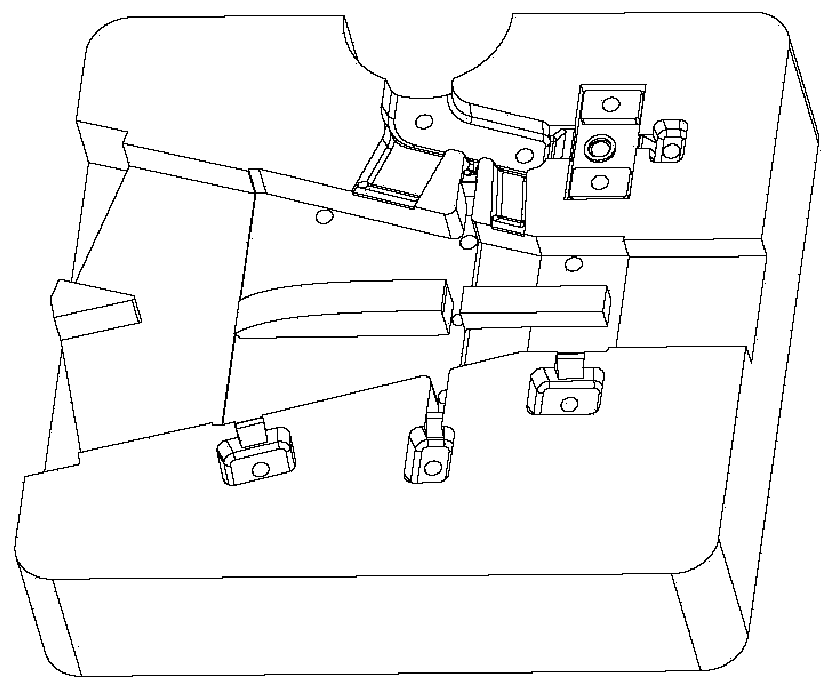

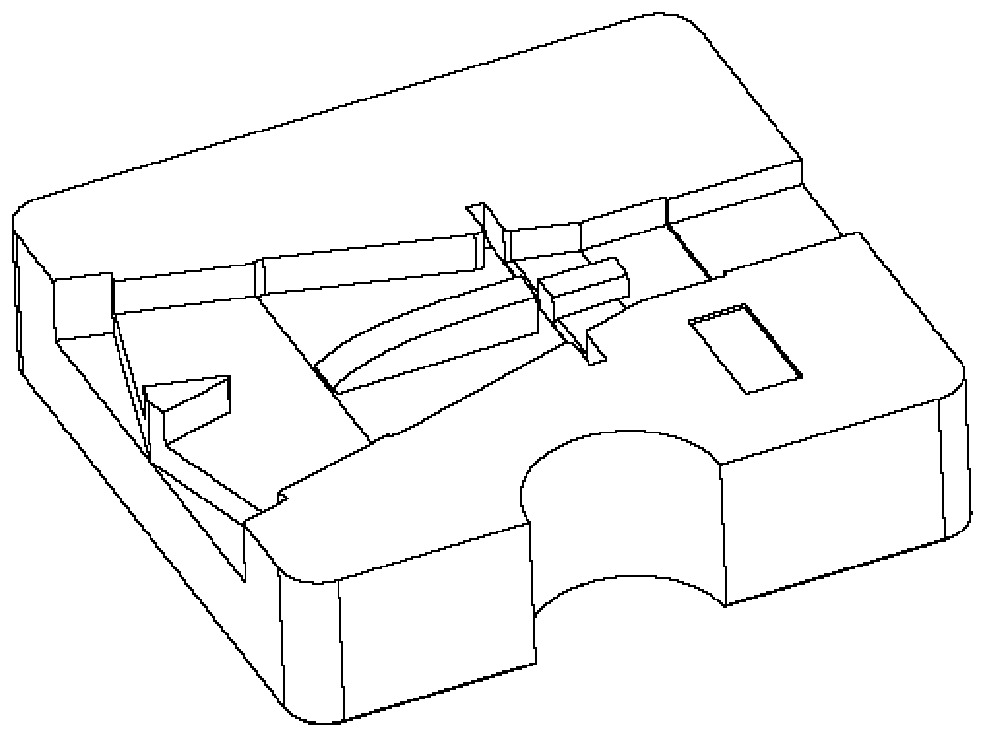

[0033] The double-ridge horn section and the small end cap are designed and manufactured according to an integrated metal mold. Metal molds include core molds and mold bases, such as Figure 2 to Figure 8 As shown, the core mold includes an inner cavity core mold and an outer core mold. The inner cavity mandrel is composed of three parts: left sliding core, right sliding core and oblique sliding core; the external mandrel is composed of a moving mandrel and a fixed mandrel; The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com