A physical dryer for preparing composite airgel self-insulating formwork

A composite airgel and self-insulation technology, which is applied in the direction of drying machine combination, progressive drying machine, drying solid materials, etc., can solve the problems of high process requirements, powder and slag loss, low drying efficiency, etc., and achieve accelerated drying process, reduce the air dust exceeding the standard, and improve the effect of drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

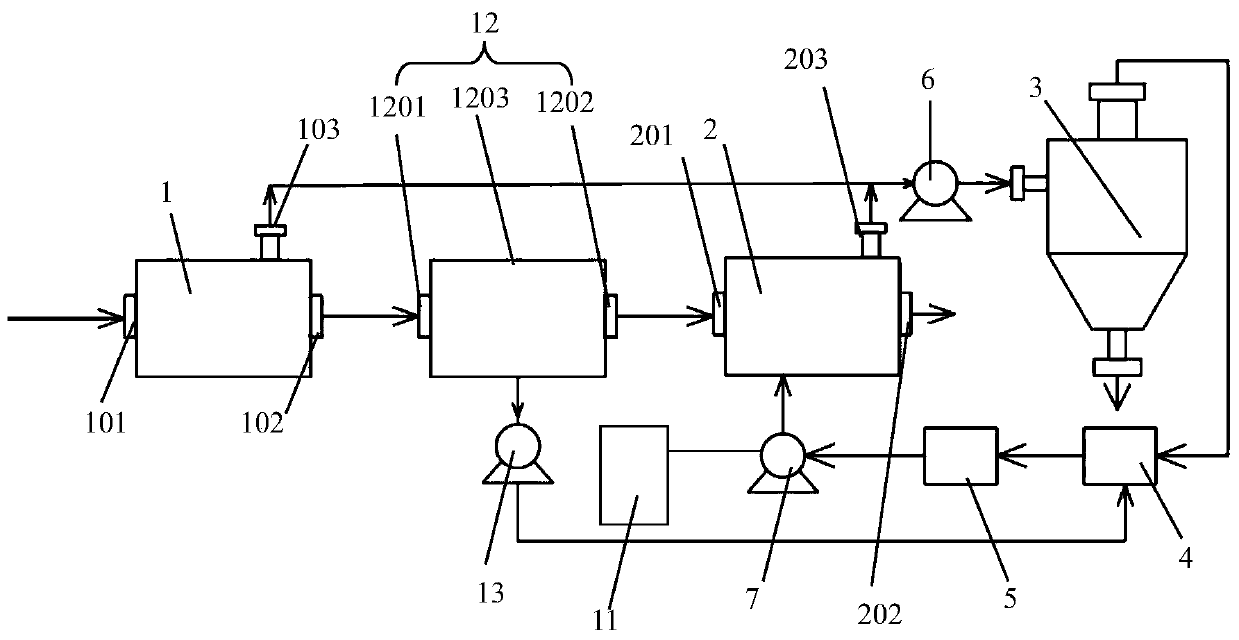

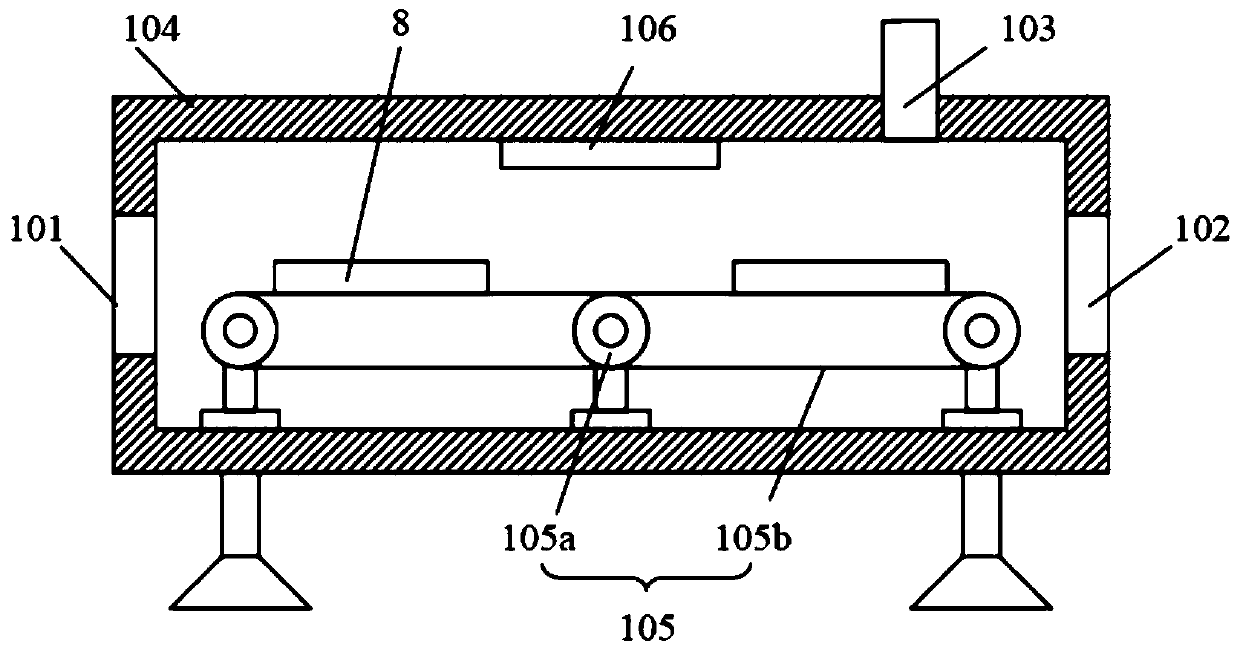

[0046] Such as figure 1 As shown, the present invention provides a physical dryer, which at least includes a first drying section 1 , a second drying section 12 and a third drying section 2 . The first drier 1 is used to carry out the first-stage drying process to the composite airgel self-insulation formwork 8 according to the mode of drying, so that the solvent in the composite airgel self-insulation formwork 8 can be evaporated under the set reaction conditions. The way is to separate the composite airgel from the thermal insulation template 8 . The second drying section is used to perform a second-stage drying treatment on the composite airgel self-insulating template 8 , so that the gas in the second drying section can penetrate the composite airgel self-insulating template 8 to take out the solvent therein. The third drying section 2 is used for performing third-stage drying treatment on the composite airgel self-insulating template 8 . Specifically, the first drying p...

Embodiment 2

[0052] This embodiment is a further improvement on Embodiment 1, and repeated content will not be repeated here.

[0053] Such as Figure 4 Shown, form the negative pressure space 14 that is the negative pressure state that air pressure is less than standard atmospheric pressure on the first side of composite airgel self-insulation template 8 approximately perpendicular to the ground direction, the gas in atmospheric environment can be based on the negative pressure state. Entering the accommodation space, and the gas located on the second side opposite to the first side of the composite airgel self-insulating template 8 can move along the direction of the second side to the first side based on the negative pressure state, so that the gas located on the second side Gas can enter the composite airgel self-insulation template 8 from the second side and discharge the composite airgel self-insulation template 8 from the first side, wherein the gas penetrating the composite airgel ...

Embodiment 3

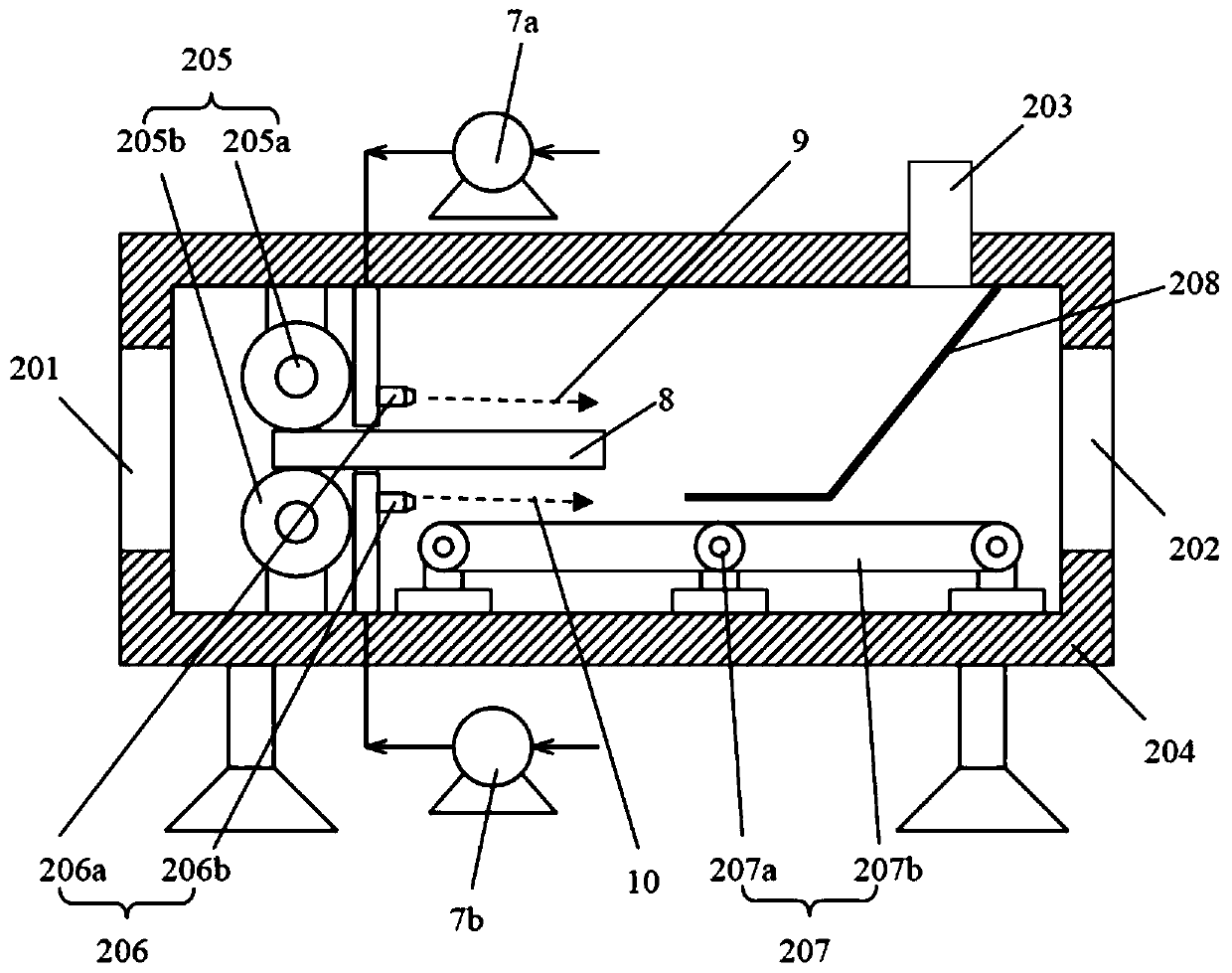

[0057] This embodiment is a further improvement on the foregoing embodiments, and repeated content will not be repeated here.

[0058] Such as image 3 As shown, the physical dryer also includes a third drying section 2 located downstream of the second drying section 12, so that the composite airgel after the second-stage drying treatment can enter the third drying section 2 from the thermal insulation template 8 to perform the third drying process. Stage drying process, wherein, the third drying part 2 is configured to perform the third stage drying process on the composite airgel self-insulation formwork 8 in an air-dried manner, and the third drying part 2 is configured to perform the third stage drying process in the following manner: The housing 204 that can be hollow is configured to accommodate the composite airgel self-insulation template 8 after the second-stage drying treatment, wherein the housing 204 is provided with a second feed port 201 and a second discharge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com