Extra-high voltage iron tower assembly lifting pole

An iron tower assembly and ultra-high voltage technology, which is applied to towers, building types, buildings, etc., can solve the problems of normal use of poles, shortened service life, time-consuming and other problems, and achieves reasonable stress, safe use, and improved construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

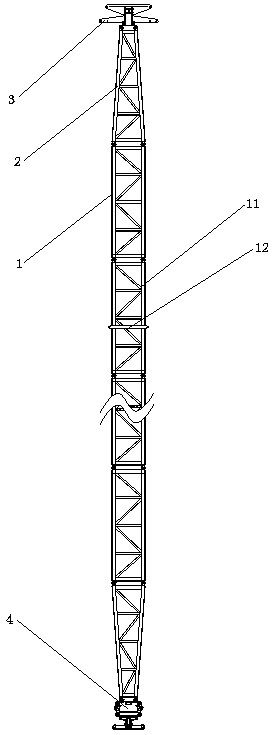

[0016] Such as figure 1 , 2 As shown, the UHV iron tower assembly pole of the present invention includes a straight section 1 , a cone section 2 , a rotating lifting head 3 and a lower supporting cap 4 .

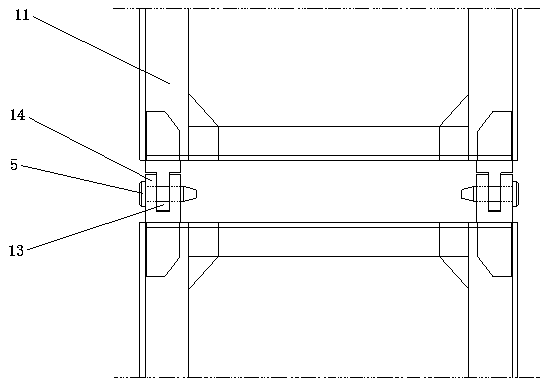

[0017] The straight section 1 is composed of a plurality of single-section straight sections 11 connected end to end; wherein, the middle section of each single-section straight section 11 is matched with a waist ring 12, and the four corners of the top are vertically protruding upwards and provided with four plug-in blocks. 13. Four sockets 14 protrude vertically downward from the four corners of the bottom end; the middle part of each socket block 13 is penetrated with a socket hole along the horizontal direction; each socket 14 is matched vertically from the center of the bottom A slot is provided, and the middle part of the groove wall on both sides of the slot is also provided with an insertion hole along the horizontal direction. The top of each single-section straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com