Dyeing vat exhaust mechanism

An exhaust mechanism and dyeing vat technology, applied in the field of machinery, can solve problems such as time-consuming and labor-intensive, and achieve the effects of high opening and closing stability, easy operation and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

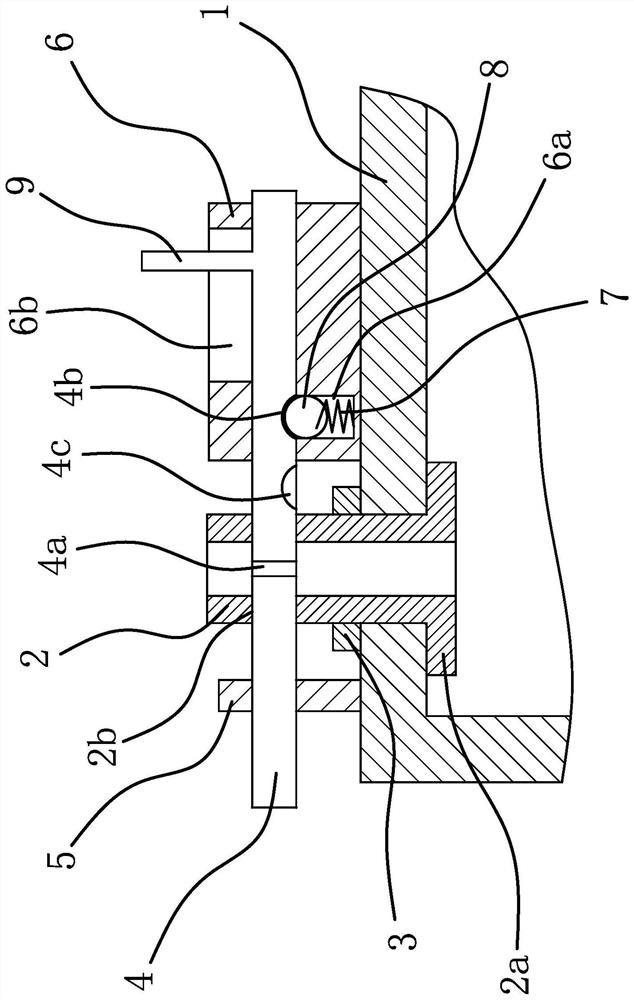

[0031] Such as figure 1 As shown, the dye vat includes a body 1 with a cavity inside, and the upper end of the body 1 has an exhaust port communicating with the inner cavity.

[0032] The exhaust mechanism of this dyeing vat is arranged at the exhaust port, including exhaust pipe 2, switching rod 4 and guiding structure. The above-mentioned exhaust pipe 2 is connected to the exhaust port of the body 1 and the outer end of the exhaust pipe 2 extends out of the body 1. The side of the exhaust pipe 2 has a connecting hole 2b through it. The switching lever 4 is arranged horizontally and has an air outlet hole 4a penetrating on the switching lever 4. In the initial state, the air outlet 4a is located outside the exhaust pipe 2. The guide The structure is located between the switching rod 4 and the body 1, and the switching rod 4 can translate relative to the exhaust pipe 2 under the action of the guide structure. When the switching rod 4 translates, the air outlet 4a can be locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com