A kind of composite hydrogel of silk fibroin and polyvinyl alcohol and its preparation method and application

A technology of composite hydrogel and silk fibroin, which is applied in the field of composite hydrogel of silk fibroin and polyvinyl alcohol and its preparation, can solve the problems of limited application range, poor mechanical properties and swelling properties, and achieve material molding Simple method, good hydrophilicity, fast toxicity and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of silk fibroin: Weigh 3g of anhydrous sodium carbonate and add it to 5L of boiling water solution, put 100-150g of silk into the boiling water solution for degumming and dry at 60°C, after drying, dissolve the silk with ternary solution, Put the solution into a dialysis bag, put it into deionized water for dialysis for 96 hours, change the water every 2 hours during the period, obtain an aqueous silk fibroin solution after dialysis, and finally obtain an aqueous silk fibroin solution with a concentration of 8 wt%.

[0031] (2) Preparation of polyvinyl alcohol solution: Weigh 6-10 g of polyvinyl alcohol (molecular weight is 31000), add 100 ml of deionized water, stir and dissolve in a water bath at 90 ° C, until the concentration after complete dissolution is 6-10 wt % polyvinyl alcohol solution.

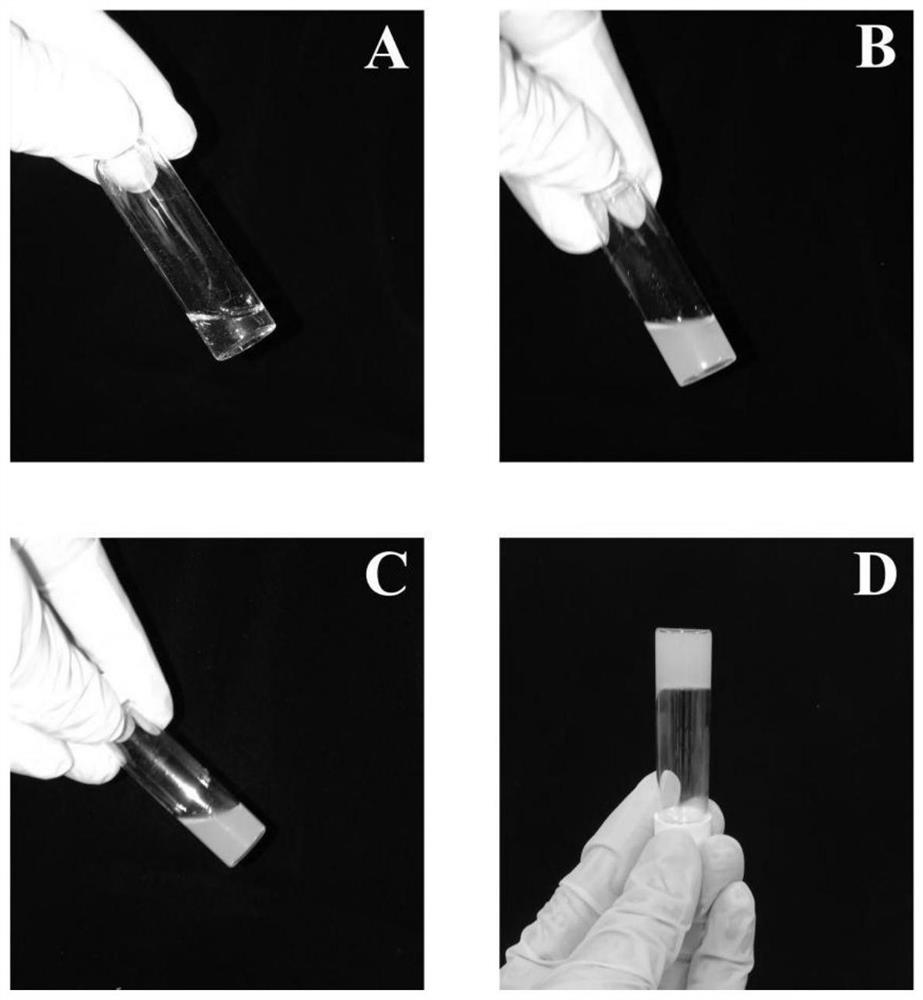

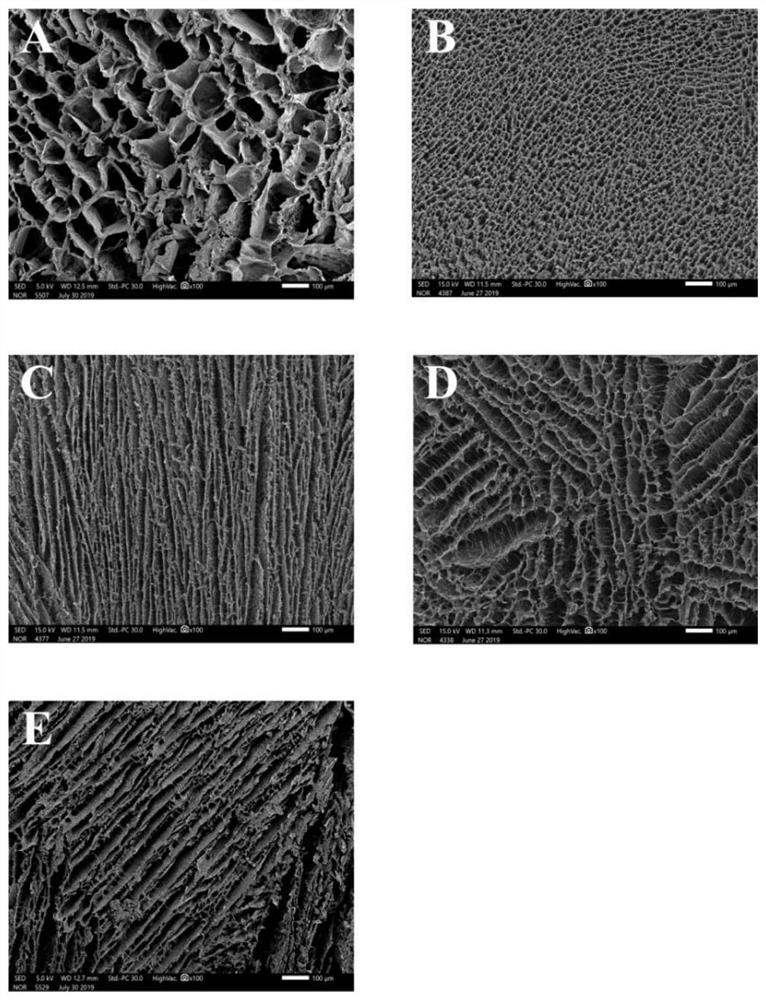

[0032] (3) Preparation of a composite hydrogel of silk fibroin and polyvinyl alcohol: get the 8wt% silk fibroin aqueous solution prepared in (1), mix it with ...

Embodiment 2

[0034] Other steps are the same as in Example 1, except that the concentration of polyvinyl alcohol prepared in step (2) is 8 wt%. (3) Add an equal volume of 8wt% polyvinyl alcohol solution. After mixing evenly, add horseradish peroxidase (HRP) and hydrogen peroxide (H 2 o 2 ) for cross-linking, finally obtaining a composite hydrogel of silk fibroin and polyvinyl alcohol.

Embodiment 3

[0036] Other steps are the same as in Example 1, except that the concentration of polyvinyl alcohol prepared in step (2) is 10 wt%. (3) Add an equal volume of 10 wt% polyvinyl alcohol solution. After mixing evenly, add horseradish peroxidase (HPR) and hydrogen peroxide (H 2 o 2 ) for cross-linking, finally obtaining a composite hydrogel of silk fibroin and polyvinyl alcohol.

PUM

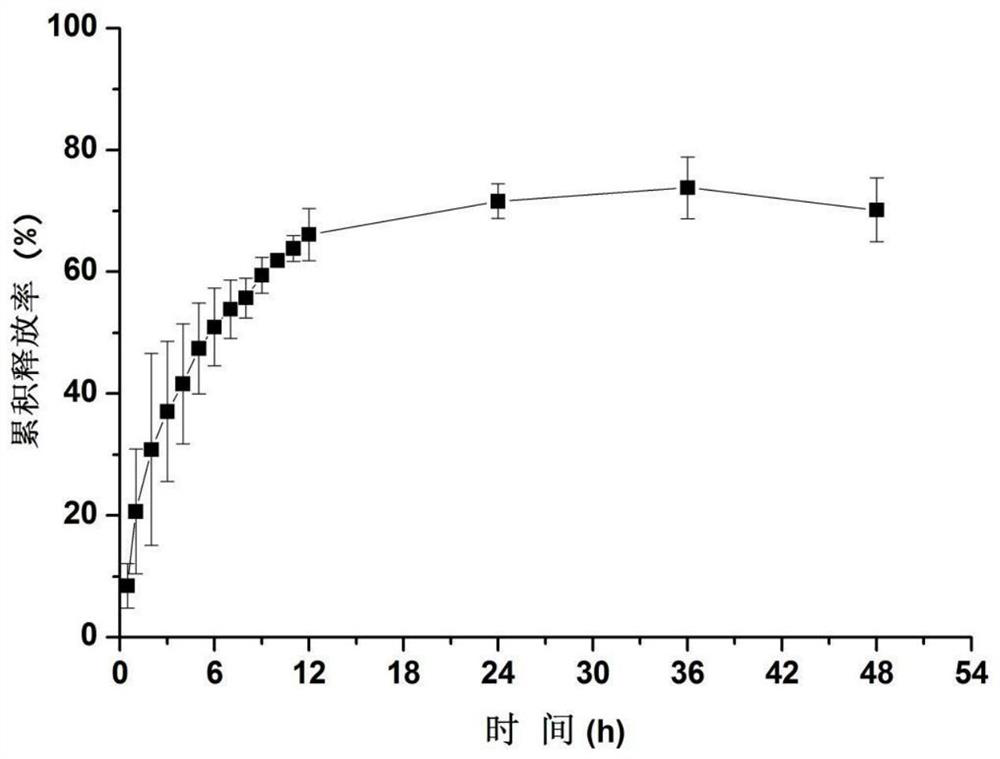

| Property | Measurement | Unit |

|---|---|---|

| cumulative release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com