Antibacterial Zn complex-porous resin composite adsorption material and preparation method thereof

A composite adsorption material, porous resin technology, applied in the preparation of organic compounds, silicon compounds, alkali metal compounds, etc., can solve the problem of difficult to sterilize and inhibit the growth of microorganisms, eliminate residual chlorine, and enrich the pore structure. , the effect of uniform crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

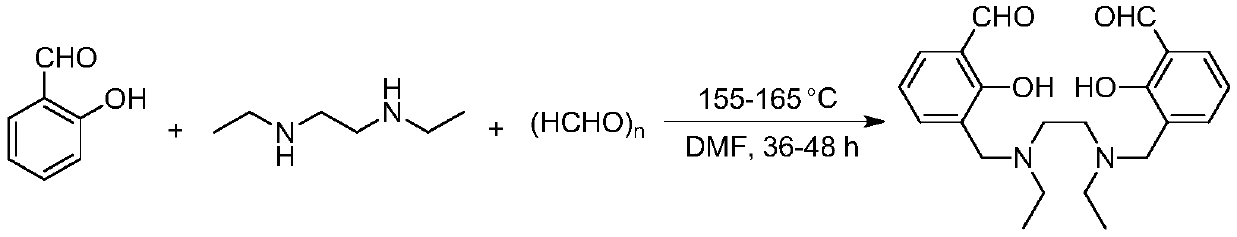

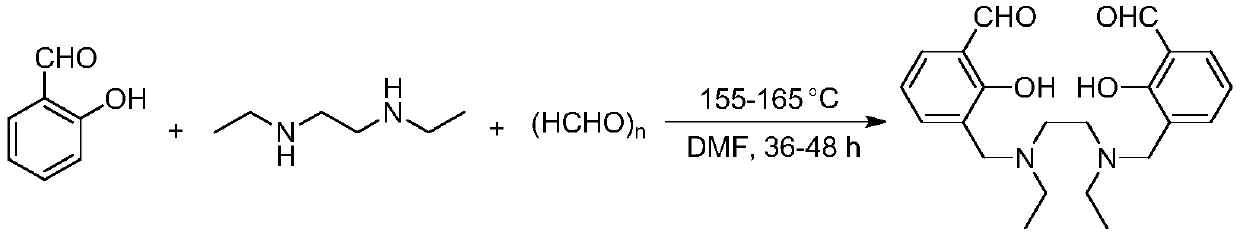

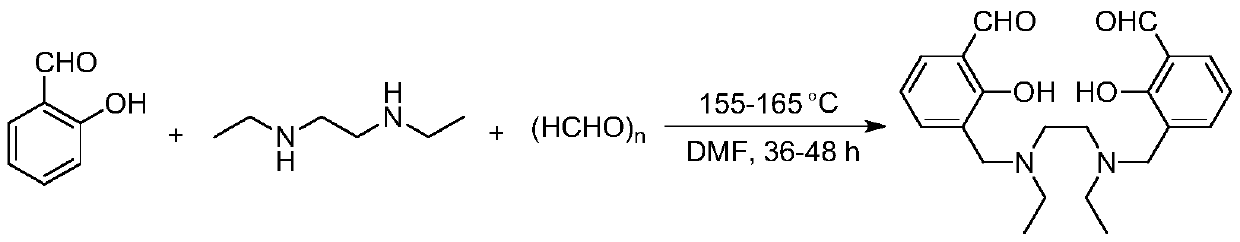

Image

Examples

preparation example Construction

[0027] The preparation method of inorganic porous adsorbent comprises the following steps:

[0028] (1) Add appropriate amount of absolute ethanol to the high planetary ball mill, and then add diopside, zeolite, biological activated carbon and calcium carbonate in sequence, the mass ratio of the four is 2-3:5-8:5-10:1, and perform ball milling , until all materials pass through a 400-600mu mesh screen, transfer the materials and absolute ethanol into a beaker, place in an ultrasonic disperser, heat to 60-80°C, ultrasonic frequency is 20-28KHz, and perform ultrasonic dispersion treatment for 2-3h. The material is placed in an oven and heated to 70-80° C., and the absolute ethanol is completely dried to obtain an inorganic composite precursor.

[0029] (2) Put the inorganic composite precursor in a calcined resistance box, heat up at a rate of 5-10°C / min, heat to 1150-1180°C, heat-preserve and calcinate for 3-5h, and anneal at 1150-1180°C for 2-3h, An inorganic porous adsorbent...

Embodiment 1

[0039] (1) Preparation of inorganic composite precursor 1: add an appropriate amount of absolute ethanol to the high planetary ball mill, and then add diopside, zeolite, biological activated carbon and calcium carbonate in sequence, and the mass ratio of the four is 2:5:5:1. Ball mill until all the materials pass through a 400mu mesh screen, transfer the materials and absolute ethanol into a beaker, place them in an ultrasonic disperser, heat to 60°C, ultrasonic frequency is 20KHz, perform ultrasonic dispersion treatment for 2 hours, and heat the materials in an oven To 70°C, completely dry the absolute ethanol to obtain the inorganic composite precursor 1.

[0040] (2) Preparation of inorganic porous adsorbent 1: put inorganic composite precursor 1 in a calcined resistance box, heat up to 1150°C at a heating rate of 5°C / min, heat-preserve and calcinate for 3h, and anneal at 1150°C for 2h to prepare Inorganic Porous Adsorbent1.

[0041] (3) Organic ligand aminated biphenyl sa...

Embodiment 2

[0047] (1) Preparation of inorganic composite precursor 2: add an appropriate amount of absolute ethanol to the high planetary ball mill, and then add diopside, zeolite, biological activated carbon and calcium carbonate in sequence, and the mass ratio of the four is 2.5:6:6:1. Ball mill until all the materials pass through a 400mu mesh screen, transfer the materials and absolute ethanol into a beaker, place them in an ultrasonic disperser, heat to 60°C, ultrasonic frequency is 22KHz, conduct ultrasonic dispersion treatment for 2 hours, and heat the materials in an oven To 70°C, completely dry the absolute ethanol to obtain the inorganic composite precursor 2.

[0048] (2) Preparation of inorganic porous adsorbent 2: put the inorganic composite precursor 2 in a calcined resistance box, heat up to 1160°C at a heating rate of 5°C / min, heat-preserve and calcinate for 4h, and anneal at 1160°C for 2h to prepare Inorganic Porous Adsorbent2.

[0049] (3) Organic ligand aminated biphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com