Composite adsorbent based on water purification sludge and powdered activated carbon and its preparation method and application

A powder activated carbon, composite adsorption technology, applied in water/sludge/sewage treatment, water pollutants, water/sewage treatment and other directions, can solve the problems of complex preparation process, poor adsorption effect, etc., to improve ammonia nitrogen removal efficiency, The effect of increasing the average adsorption pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Based on the composite adsorbent of water purification sludge and powdered activated carbon, the specific production steps are as follows:

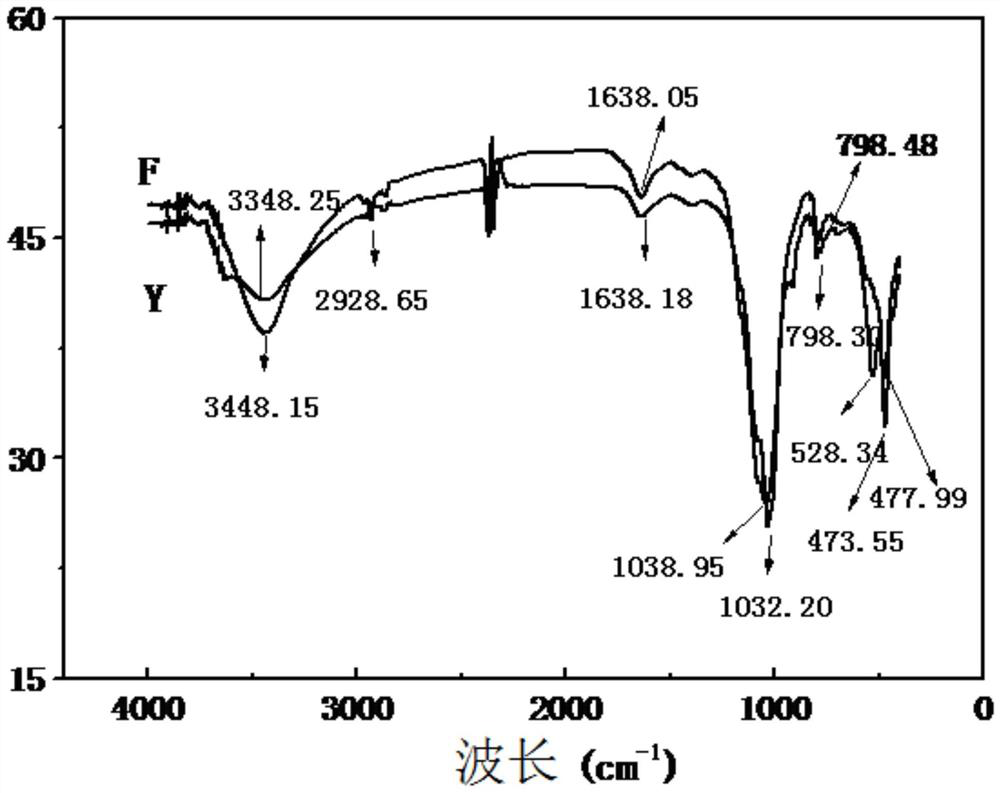

[0021] The purified water sludge retrieved from the water plant in Suzhou High-tech Zone was put into a blast drying oven and dried at a temperature of 100°C for 24 hours, and then pulverized to 100-140 mesh in a pulverizer to obtain pulverized purified water sludge. Take pulverized water purification sludge and powdered activated carbon with a mass ratio of 9:1 (purchased from Sinopharm Chemical Reagent Co., Ltd., the specific surface is about 900 m 2 / g, the particle size is 110 mesh to 120 mesh) for mixing, add 50 ml of distilled water, stir evenly, and use a granulator to extrude a cylinder with a diameter of 3 mm (the diameter and height of the cross-sectional circle of the cylinder are not limited), which is a shaped body . The extruded molded body was air-dried under natural conditions, then placed in a blast drying oven fo...

Embodiment 2

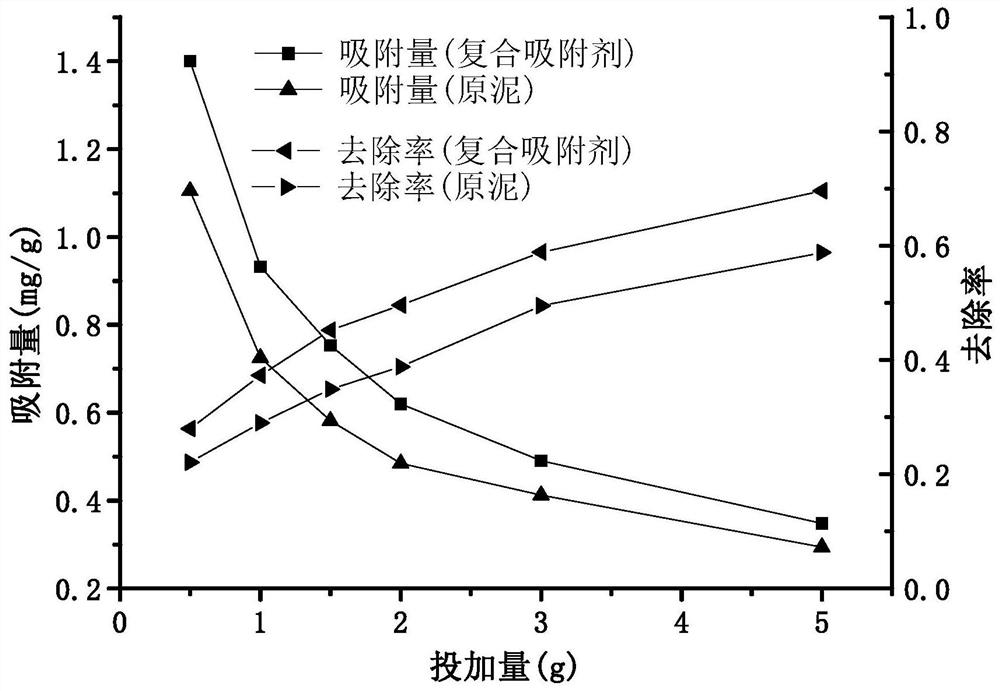

[0028] The composite adsorbent based on water purification sludge and powdered activated carbon has a good removal effect of ammonia nitrogen in water. Ammonia nitrogen wastewater was simulated with ammonium chloride aqueous solution, and ammonium chloride was of analytical grade. Add adsorbents of different masses (0.5g, 1g, 1.5g, 2g, 3g, 5g) into the conical flask, add 50mL of 50mg / L ammonia nitrogen wastewater, shake for 2 hours, the shaking temperature is 25 ℃, and the shaking rate is 120r / min. After the adsorption was completed, samples were taken from the conical flask for centrifugation, and the ammonia nitrogen concentration was measured. The effect of the dosage of raw mud adsorbent and composite adsorbent on the removal of ammonia nitrogen is as follows: image 3 shown.

[0029] from image 3 It can be seen that the adsorption capacity of the composite adsorbent is higher than that of the original mud under the same dosage. With the increase of adsorbent dosage,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com