A kind of substrate arrangement cache device

A cache and substrate technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as affecting production efficiency, wasting cover plates, fragments, etc., to achieve the effect of avoiding the risk of fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is:

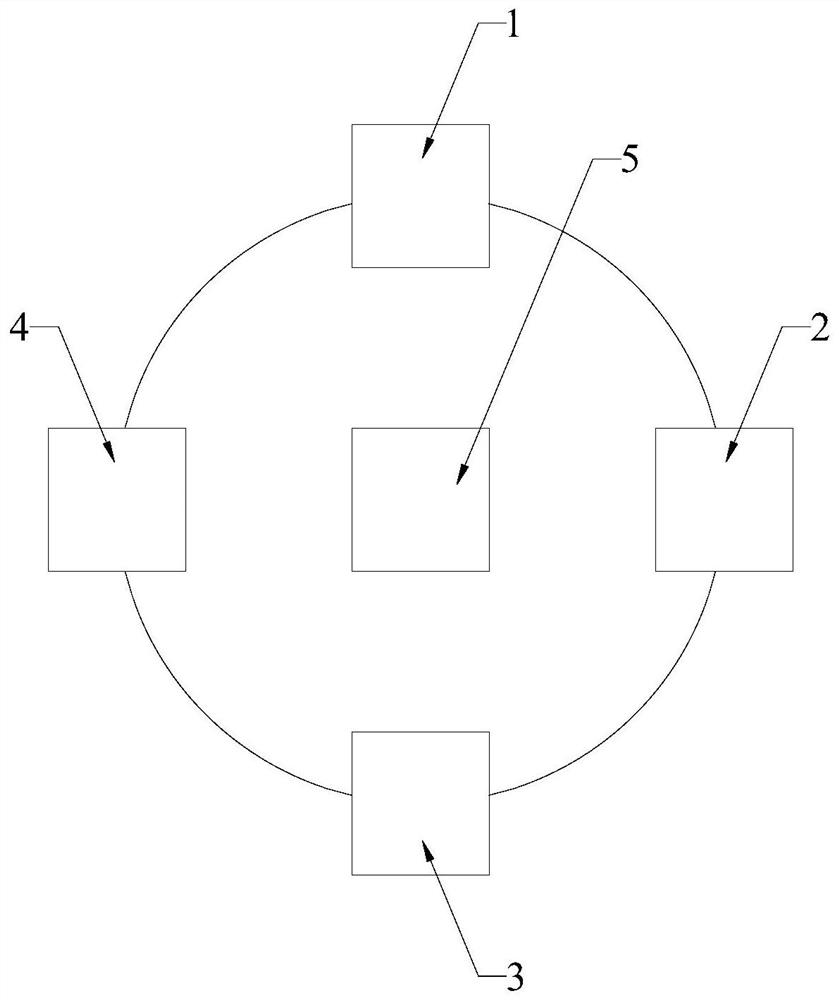

[0040] Please refer to figure 1 , a substrate buffering device 4, including a glue coating device 1, a pressing device 2, a frame glue curing device 3, a buffering device 4, an extraction device 5 and a processor;

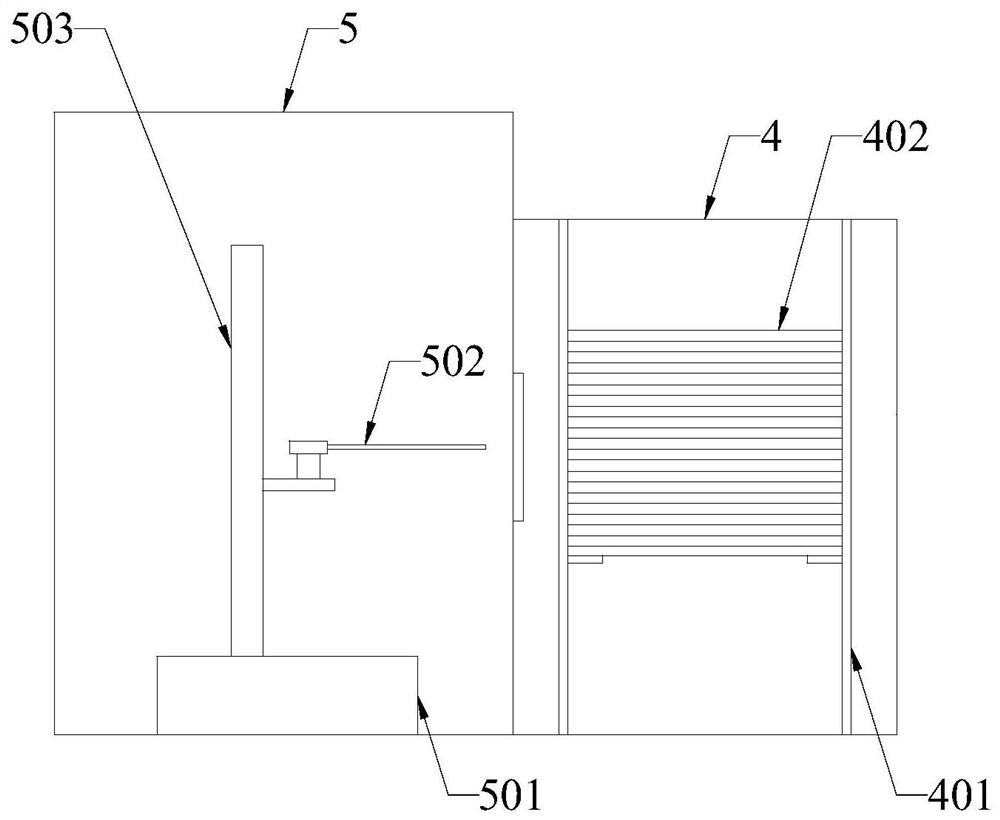

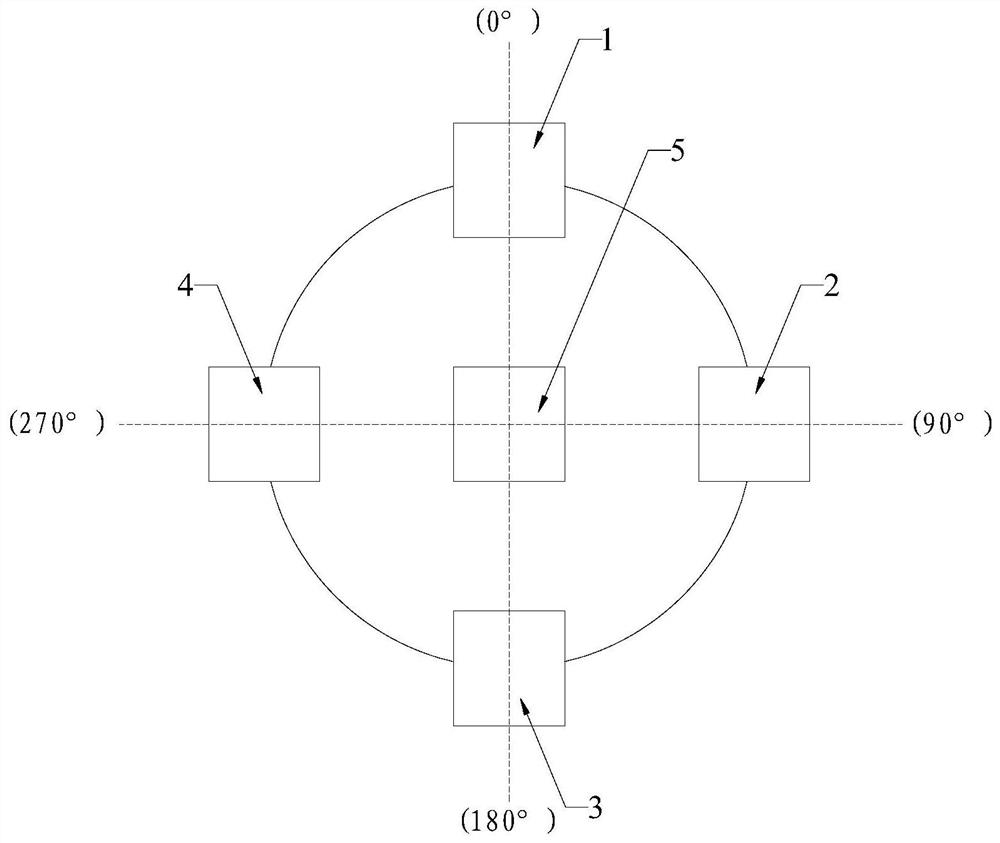

[0041] The glue coating device 1, the pressing pair group device 2, the frame glue curing device 3 and the sheet buffer device 4 are sequentially connected and distributed in a ring (such as figure 1 and Figure 4Two kinds of distribution conditions), the glue coating device 1, the pressing pair group device 2, the frame glue curing device 3 and the sheet buffer device 4 are evenly distributed on the ring-shaped equal points, and the extraction device 5 is arranged on the The central position of the ring, the extraction device 5 includes a horizontal turntable 501 and a manipulator 502 arranged on the horizontal turntable 501, the glue coating device 1, the pressing and pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com