Dedusting system applied to cupola furnace

A technology of dust removal system and cupola, which is applied in the direction of furnace, furnace components, and process efficiency improvement, etc., can solve the problems of large instantaneous change of air temperature, failure of filter material, and difficulty in accurate calculation of captured air volume, so as to reduce cost expenditure, manufacture Cost reduction and complete desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

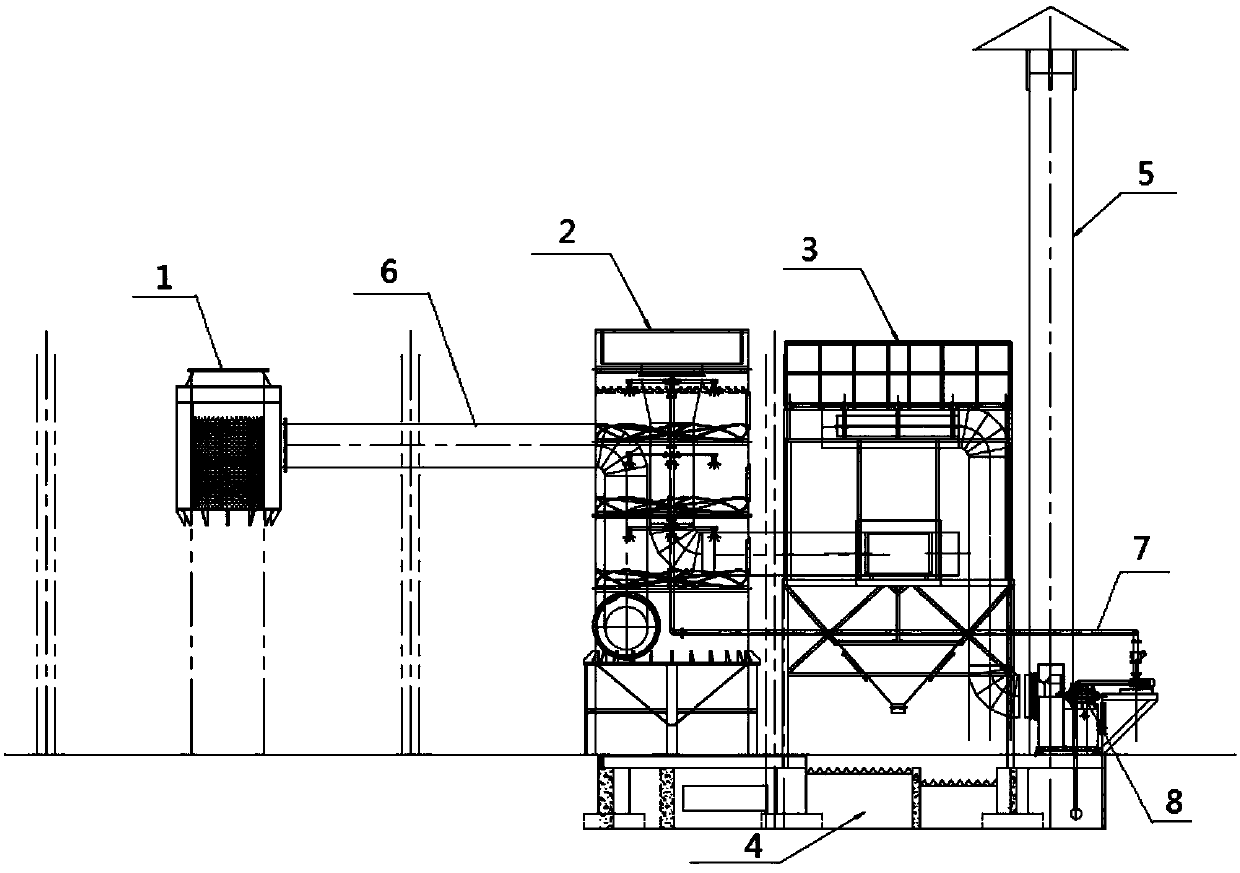

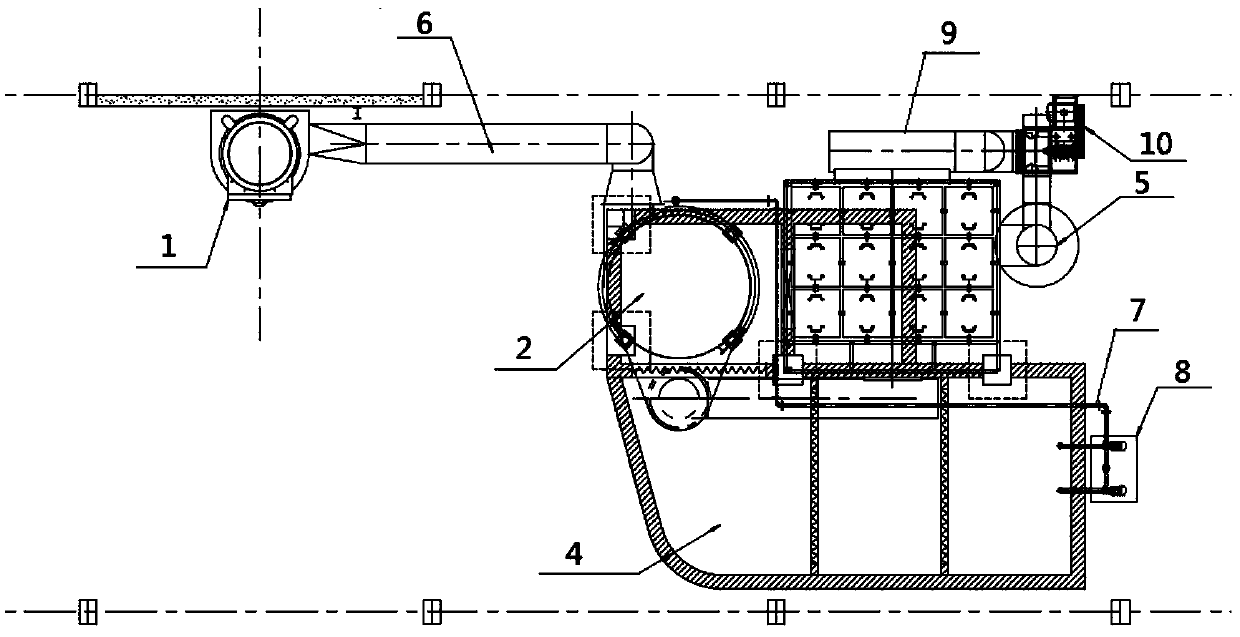

[0047] like figure 1 , 2 As shown, the dust removal system applied to the cupola includes a dust removal hood, a desulfurization temperature adjustment tower, a filter cartridge dust collector, a circulating alkaline water pool and a chimney arranged above the cupola feeding port. The dust removal hood, desulfurization temperature adjustment tower, filter The desulfurization and temperature-adjusting towers are connected to a water pipeline, and the water pipeline is connected to a circulating water pump. The circulating water pump is set on the circulating alkaline water pool. The filter cartridge dust collector and the chimney pass through the air outlet The pipe is connected, and an exhaust fan is arranged on the air outlet pipe.

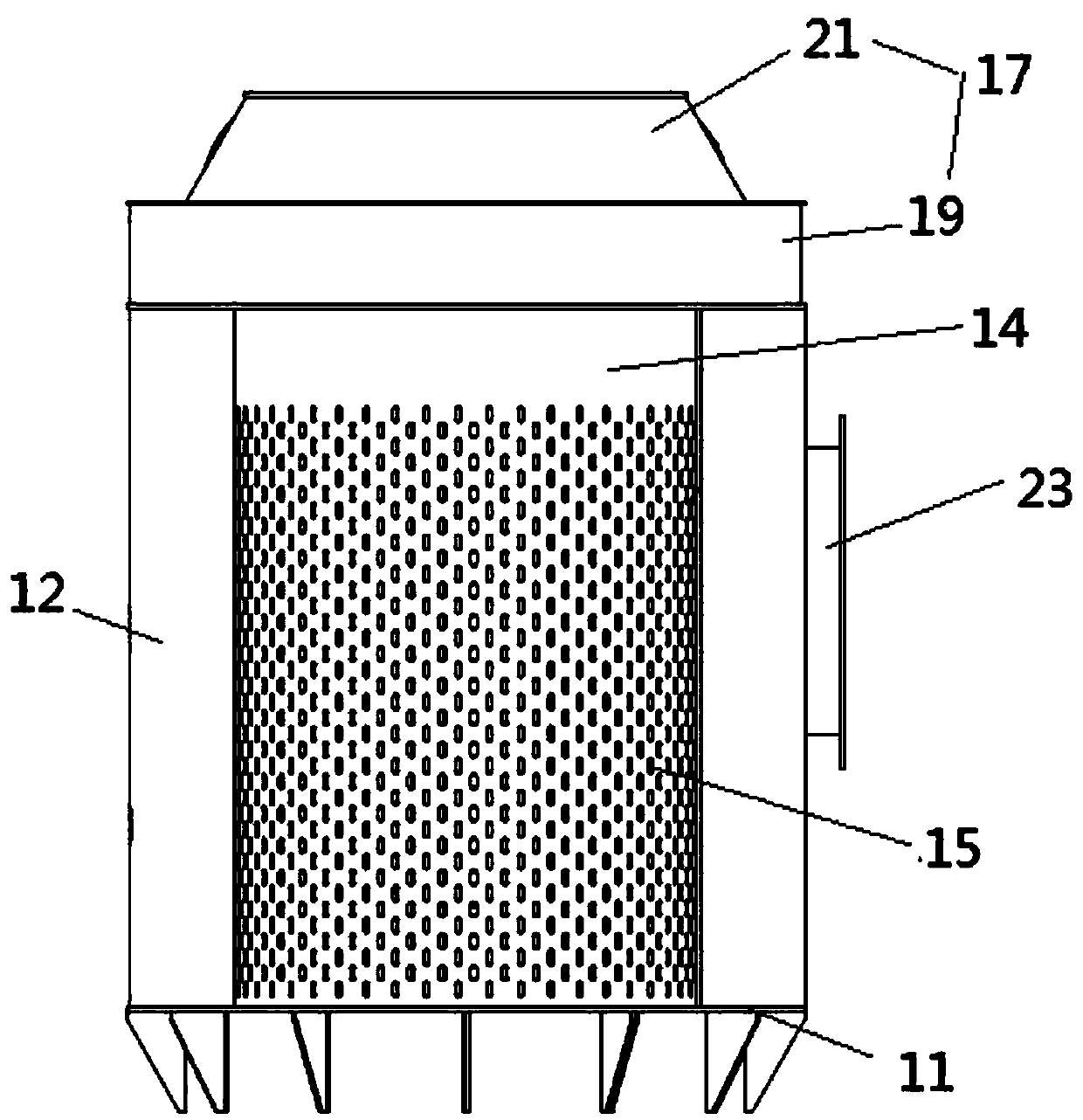

[0048] like Figure 3-5 As shown, the dust removal hood includes a fixed base set above the charging port of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com