Trichoderma harzianum strain from Tibet for producing cellulase and application of trichoderma harzianum strain

A technology of cellulase and lignocellulose, applied in the field of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Screening and biological identification of Trichoderma harzianum LZ117

[0043] (1) Screening of Trichoderma harzianum LZ117

[0044] Put the plant and soil samples collected in different geographic locations in the Tibet plateau into 50mL sterile centrifuge tubes, add 20mL of sterilized pure water, vortex fully for 60s, and carry out gradient dilution of the sample suspension (10 2 After that, 100 μL of the diluted sample solution was taken and spread on Mandels solid medium with cellulose as the single carbon source, in which 1% (weight / volume) streptomycin was added to inhibit bacterial growth. After culturing at 25°C for 48 hours, observe the production of the transparent circle. As a result, it was found that among the 35 samples, more than 10 samples had cellulose degradation transparent circles in the coated flat plates. Scraping and diluting the spores of filamentous fungal strains capable of degrading cellulose selected from each plate (or picking t...

Embodiment 2

[0052] The growth state of embodiment 2 Trichoderma harzianum LZ117 in different carbon source media, different temperatures

[0053] Inoculate a small amount of spores or hyphae of Trichoderma harzianum LZ117 into MEA medium to produce spores, culture in an incubator at 28°C for 7-10 days, wash fresh conidia with sterile distilled water and filter them with sterilized 6-layer gauze to prepare spore suspension. Measure the concentration of the spore suspension through a hemocytometer and dilute to 10 7 individual / mL, then take 2 μL of spore suspension and inoculate them into the center of Mandels solid medium and MEA solid medium plates containing 2% (weight / volume) different carbon sources (such as glucose, lactose, cellulose), respectively, and place Cultivate at 4°C, 15°C, 20°C and 28°C for 5 days, and observe the growth state of bacteria in each medium. The results showed that the growth of LZ117 strain was significantly inhibited when cultured at 4°C under different car...

Embodiment 3

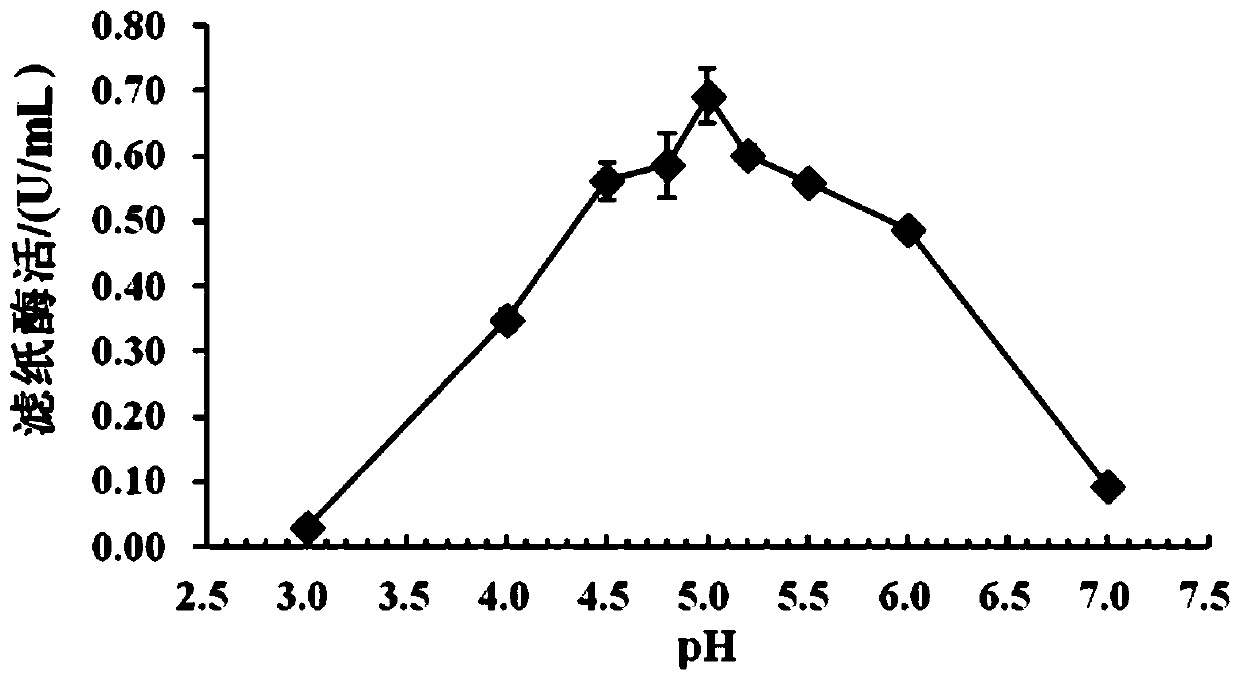

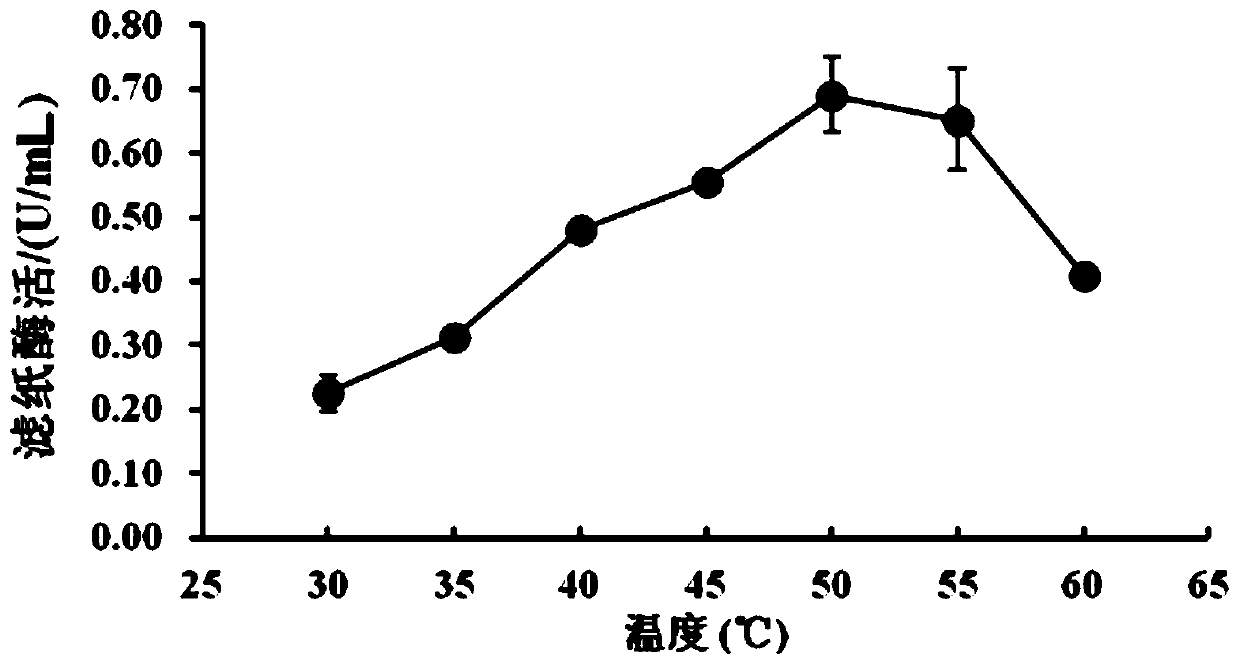

[0054] Example 3 Trichoderma harzianum LZ117 extracellular cellulase enzymatic properties

[0055] The filter paper enzyme activity of the extracellular cellulase of the LZ117 strain was measured by phosphate-citrate buffer solution of different pH (pH 3.0-7.0) at 50°C. Experiments show that the filter paper has the highest enzyme activity under the condition of pH 5.0, the results are shown in the attached figure 1 . At the same time, under the condition of pH 5.0, different enzyme reaction temperatures (30°C, 35°C, 40°C, 45°C, 50°C, 55°C and 60°C) were changed to measure the activity of extracellular cellulase filter paper. Experiments show that it has the highest filter paper enzyme activity at 50°C, the results are shown in figure 2 . Finally, the optimal temperature and pH value of the extracellular cellulase were determined to be 50°C and pH 5.0, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com