Method for preparing macromolecule composite material antenna

A composite material and composite material board technology, applied in the field of antenna communication, can solve the problems of huge time-consuming punching process, inability to perform interconnection, large dielectric loss, etc., to avoid damage and frequency changes, and the preparation method is simple and easy. Operation, frequency and effect of high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

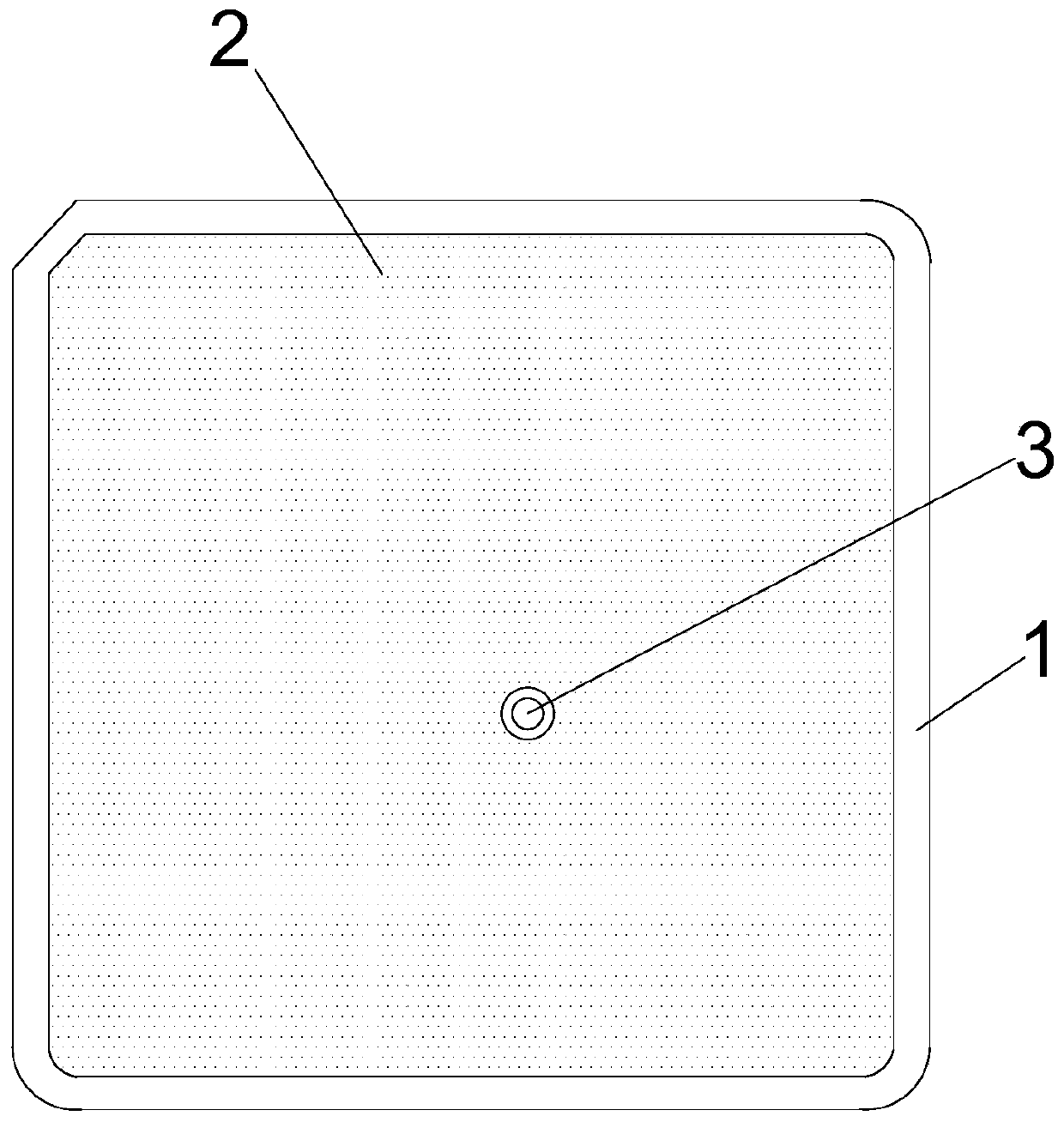

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0034] A preferred embodiment of a method for preparing a polymer composite antenna, comprising the steps of:

[0035] Step 1, the selection of organic polymer materials: select materials with a frequency of 1-100GHz and a dielectric loss tangent (tanδ) less than 0.005, such as polyphenylene ether (PPE), polytetrafluoroethylene (PTFE), liquid crystal material (LCP ) and one or more of materials such as epoxy resin;

[0036] In this embodiment, PPE is selected, and the chemical name of PPE is poly-2,6-dimethyl-1,4-phenylene ether. There is no strong polar group in the molecular structure of PPE resin, the electrical properties are stable, and it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com