Environment-friendly high urea linkage fast curing single component polyurea material and preparation method thereof

A fast-curing, high-urea bond technology, which is applied in the field of environment-friendly high-urea-bond fast-curing one-component polyurea material and its preparation, one-component polyurea material and its preparation field, can solve the problem of long curing time, low content of urea bond in the coating, Slow and other problems, to achieve the effects of shortened curing time, 100% solid content, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The following is a specific example of an environmentally friendly high urea bond single-component polyurea material provided by the present invention, and the specific formula ratio is shown in Table 1:

[0071] Table 1 Composition and content

[0072]

[0073]

[0074] Wherein, the NCO content of the prepolymer of this embodiment is 11.8%, and the number of moles of NCO can be calculated, and then 2-methylimidazole is 4 times of the number of moles of NCO.

[0075] Due to the relatively high viscosity of the polyurea-type liquid filler, it is easy to hang on the wall during the production process, so it should be produced in a larger amount than the actual amount used during production, and then take out the required amount from the produced polyurea-type liquid filler. Serving size is used.

[0076] The preparation method of the above-mentioned environment-friendly high urea bond rapid curing single-component polyurea material comprises the following steps:

...

Embodiment 2

[0102] The following is a specific example of another environmentally friendly high urea bond single-component polyurea material provided by the present invention, and the specific formula ratio is shown in Table 3:

[0103] Table 3 Composition and content

[0104]

[0105]

[0106] Wherein, the preparation method of the above-mentioned environment-friendly high urea bond rapid curing single-component polyurea material comprises the following steps:

[0107] (1) Prepare blocked isocyanate prepolymer, the specific steps are as follows:

[0108] 1) Reaction conditions: nitrogen protection;

[0109] 2) The above-mentioned polyols PTMG2000 and PCDL2000, the hydroxyl chain extender BDO, and the hydroxyl cross-linking agent TMP are respectively subjected to water removal treatment, and the above-mentioned polyols PTMG2000 and PCDL2000, the hydroxyl chain extender BDO and the hydroxyl cross-linking agent TMP are respectively added to the high-speed Disperse in a vacuum kettle...

Embodiment 3

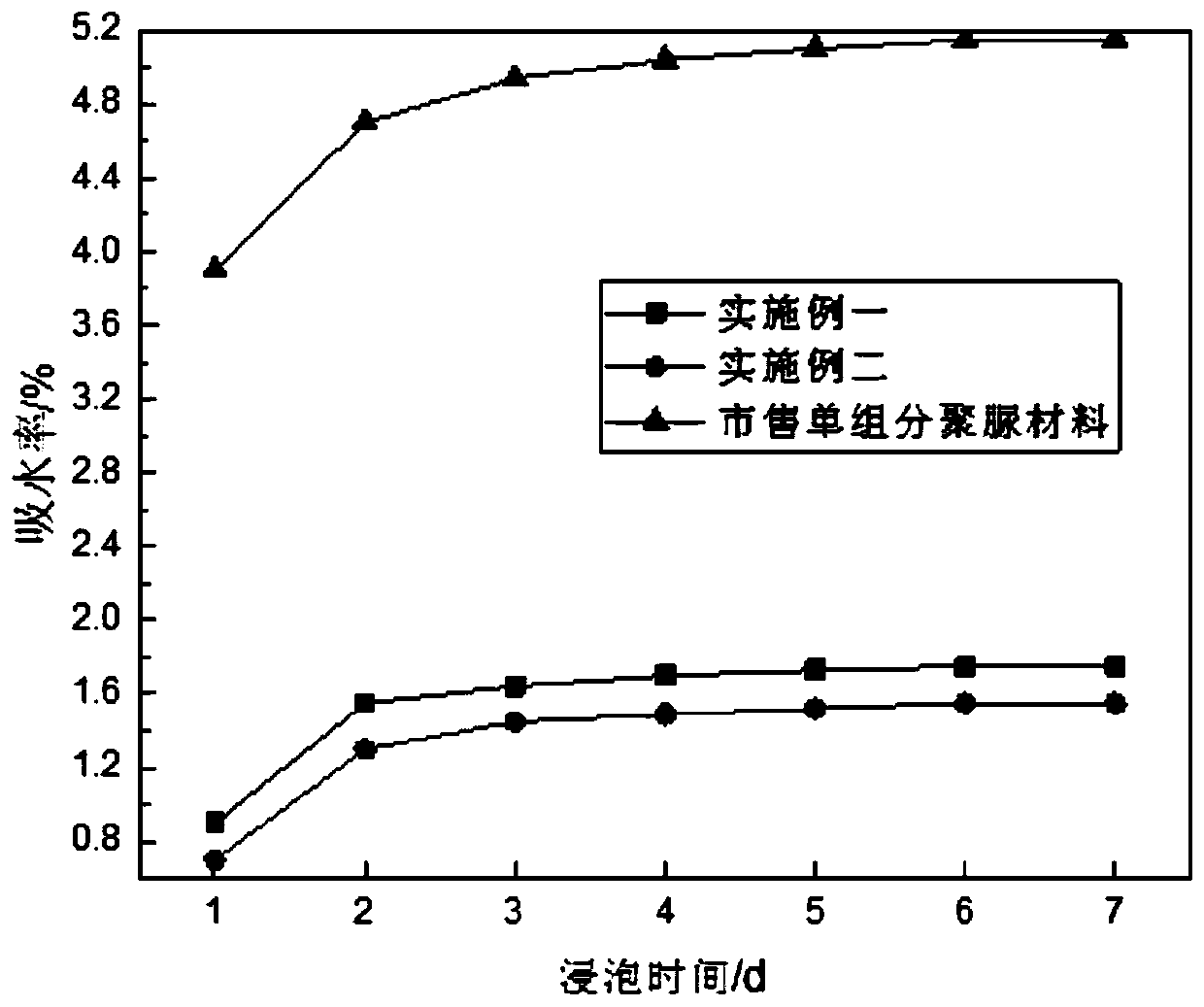

[0132] According to the test method of 7.14 of the national standard GB / T23446-2009, the environmental protection type high urea bond rapid curing single-component polyurea material and the commercially available single-component polyurea material prepared by embodiment 1 and embodiment 2 are tested for water absorption, the result Such as image 3 shown, from image 3 It can be seen that the water absorption rate of the environment-friendly high urea bond rapid curing one-component polyurea material prepared in Example 1 and Example 2 is much lower than that of the commercially available one-component polyurea material.

[0133] The low water absorption rate is mainly due to the high urea bond of the material, and the low water absorption rate means that when used in a water environment, it absorbs no or less water, and the molecular structure is not affected by water and changes, which means it has good performance in the water environment. The stability and durability are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com