Cationic polyurethane-polyurea water dispersion, and preparation method and application thereof

A cationic, polyurethane technology, used in polyurea/polyurethane coatings, coatings, etc., to solve problems such as film formation and stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

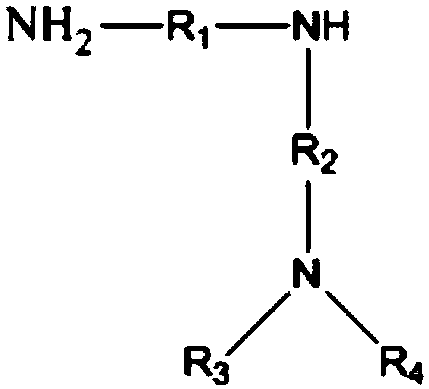

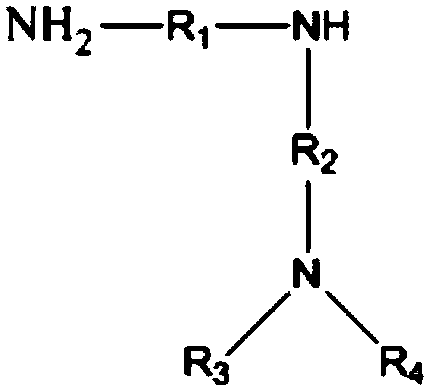

Method used

Image

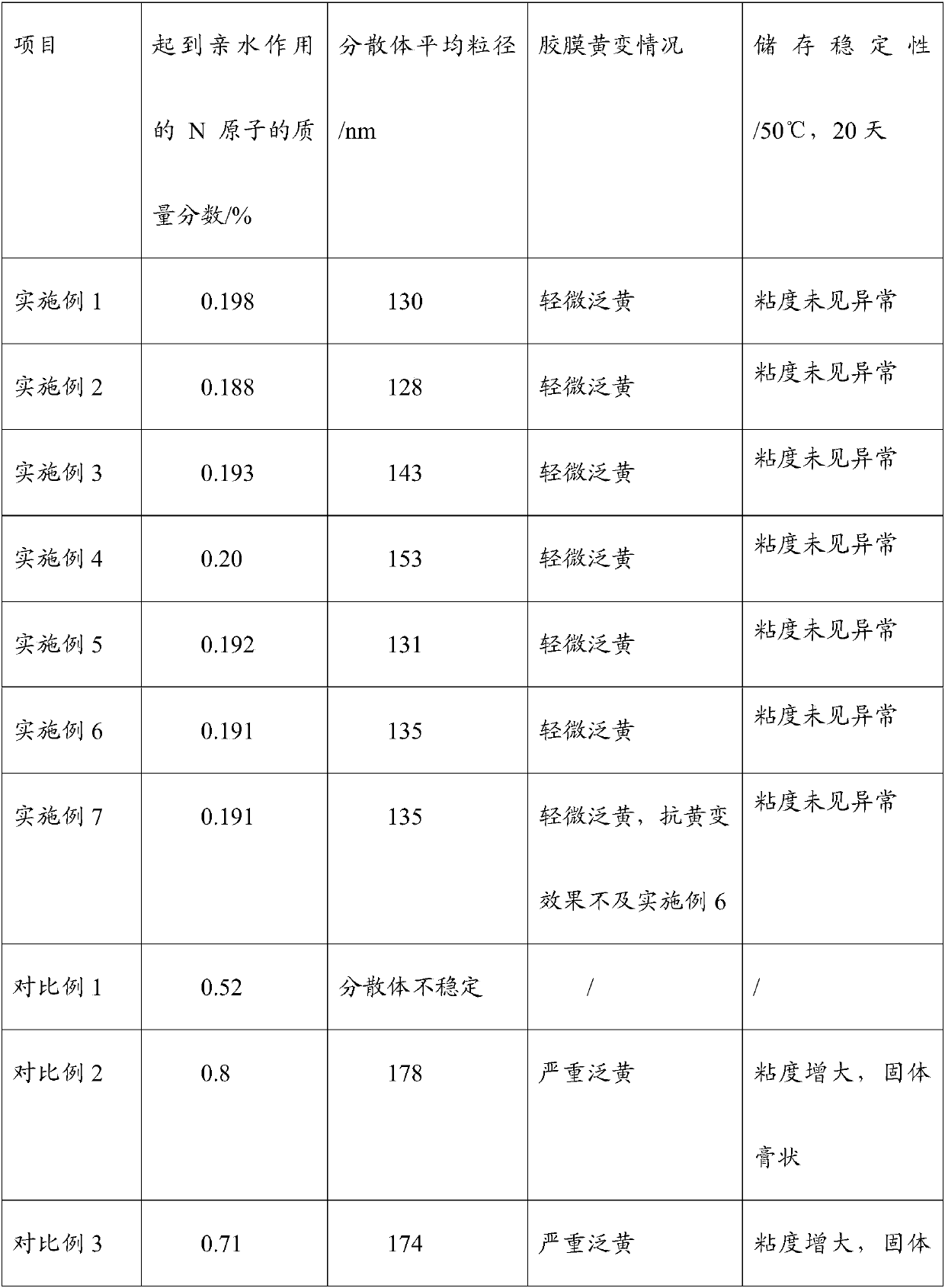

Examples

Embodiment 1

[0079] Add 276g of dehydrated polyester polyol II (component b), 57.6g of polyisocyanate I (component c), 1.8g of dehydrated Ymer 120 (component d), 40g of acetone into a nitrogen inlet and outlet In a 1 L four-neck round bottom flask, the mixture was stirred at 60-90°C until -NCO reached 1.80 wt%. Add 460g of acetone to dilute and lower the temperature to below 40°C and add 7.0g of N,N-bis(3-aminopropyl)methylamine (component a) diluted 5 times with acetone to react for about 15min, then add 2.9g of acetic acid (component a) Part e) Neutralize for about 5 minutes, add 1.6g of composite antioxidant (component i) and stir evenly, add 676g of deionized water under rapid stirring to disperse. A solvent-free cationic polyurethane-polyurea dispersion is obtained after separation of the acetone by distillation. It has a solids content of 38 wt%, an average particle size of 130 nm, and a pH of 4.5. The mass fraction of N atoms playing a hydrophilic role is 0.198wt% (based on solid ...

Embodiment 2

[0081] Add 200g of dehydrated polyester polyol I (component b), 105g of polyisocyanate I (component c), 4.0g of dehydrated MPEG-1200 (component d), 31g of acetone into a nitrogen inlet and outlet In a 1L four-neck round bottom flask, stir the mixture at 60-90°C until -NCO reaches 6.56wt%, then cool down to 40-50°C and add 12.6g of 1,2-propanediol (component f) and 32g of acetone to continue the reaction Until -NCO reaches 2.55wt%, add 436g of acetone to dilute and lower the temperature to below 40°C, add 6.5g of N,N-bis(3-aminopropyl)methylamine (component a) diluted 5 times with acetone under rapid stirring and 5g of isophorone diamine (component g), reacted for about 15min, then added 2.69g of acetic acid (component e) for neutralization for about 5min, added 1.68g of composite antioxidant (component i) and stirred evenly, under rapid stirring Add 499 g of deionized water to disperse. A solvent-free cationic polyurethane-polyurea dispersion is obtained after separation of t...

Embodiment 3

[0083] Add 250g of dehydrated polyether polyol I (component b), 65g of polyisocyanate II (component c), 4.0g of dehydrated MPEG-1200 (component d), 31.9g of acetone into a nitrogen inlet In the outlet 1L four-neck round bottom flask, stir the mixture at 60-90°C until -NCO reaches 5.91%, cool down to 40-50°C, add 14.0g of 1,2-propylene glycol (component f) and 33g of acetone to continue the reaction Until -NCO reaches 1.32%, add 444g of acetone to dilute and lower the temperature to below 40°C, add 7.5g of N,N-dimethyldipropylenetriamine (component a) diluted 5 times with acetone under rapid stirring, and react for about 15min , then add 2.69g of acetic acid (component e) for neutralization for about 5min, add 1.8g of composite antioxidant (component i) and stir evenly, and add 523g of deionized water under rapid stirring to disperse. A solvent-free cationic polyurethane-polyurea dispersion is obtained after separation of the acetone by distillation. It has a solids content of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com