Deep dehydration reagent for solid-phase sludge

A deep dehydration and medicament technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as inability to meet the technical needs of sludge dehydration upgrading and upgrading, and achieve a reduction in land occupation Small size, improved processing capacity, continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

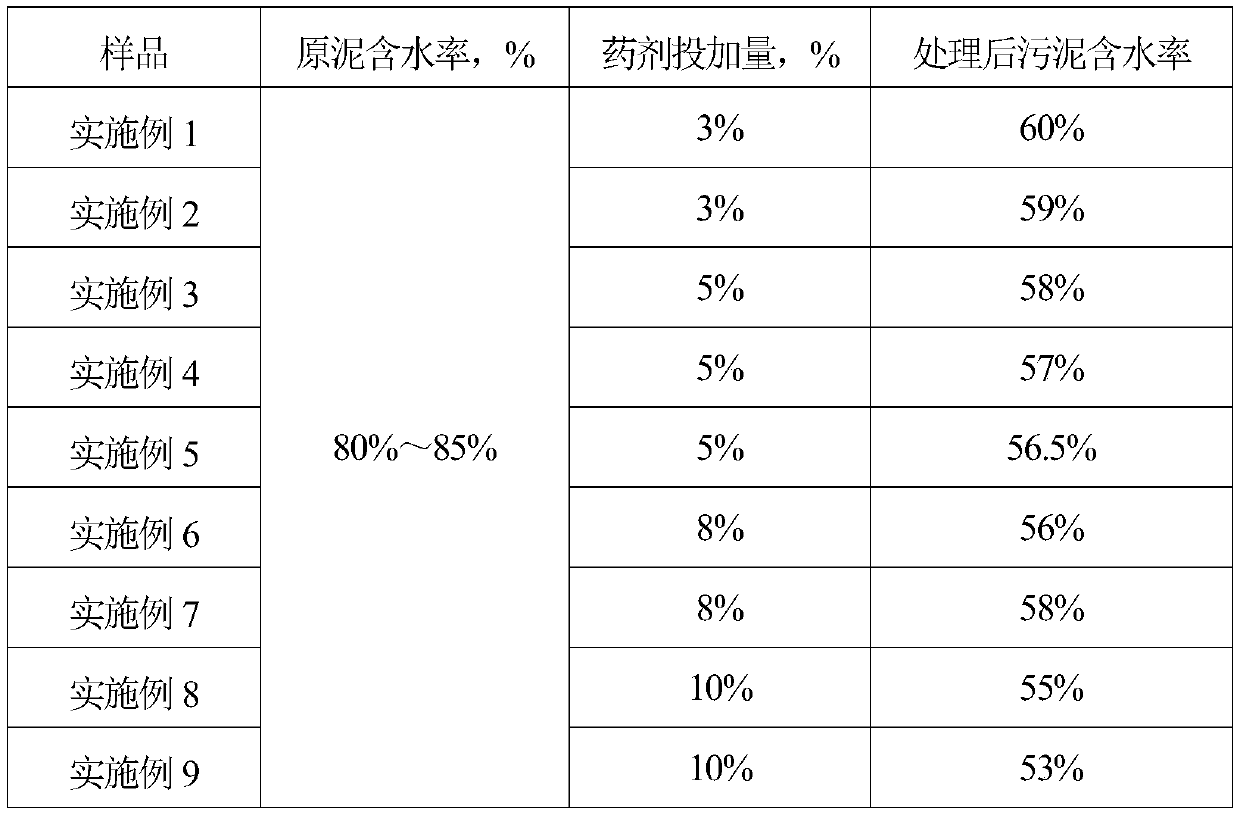

Examples

Embodiment 1

[0024] The dehydrating agent of the present embodiment is made up of following material:

[0025] Inorganic flocculant: 5g polyaluminum chloride;

[0026] Seepage drag reducer: 0.1g polyethylene oxide;

[0027] Cured proppant: 94.8g fly ash;

[0028] Wall breaking agent: 0.1g potassium permanganate.

Embodiment 2

[0030] The dehydrating agent of the present embodiment is made up of following material:

[0031] Inorganic flocculant: 20g polyaluminum chloride;

[0032] Seepage drag reducer: 1.0g polyethylene oxide;

[0033] Cured proppant: 76.0g fly ash;

[0034] Wall breaking agent: 3.0g potassium permanganate.

Embodiment 3

[0036] The dehydrating agent of the present embodiment is made up of following material:

[0037] Inorganic flocculant: 10g polyaluminum chloride;

[0038] Seepage drag reducer: 0.5g polyethylene oxide;

[0039] Cured proppant: 89.0g fly ash;

[0040] Wall breaking agent: 0.5g potassium permanganate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com