Conveying system of container yard and wharf container conveying system

A container yard and conveying system technology, which is applied in the field of container yard conveying system and wharf container conveying system, can solve problems such as high safety risks, and achieve the effects of many resources at loading and unloading points, basic balance of workload, and good energy saving and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

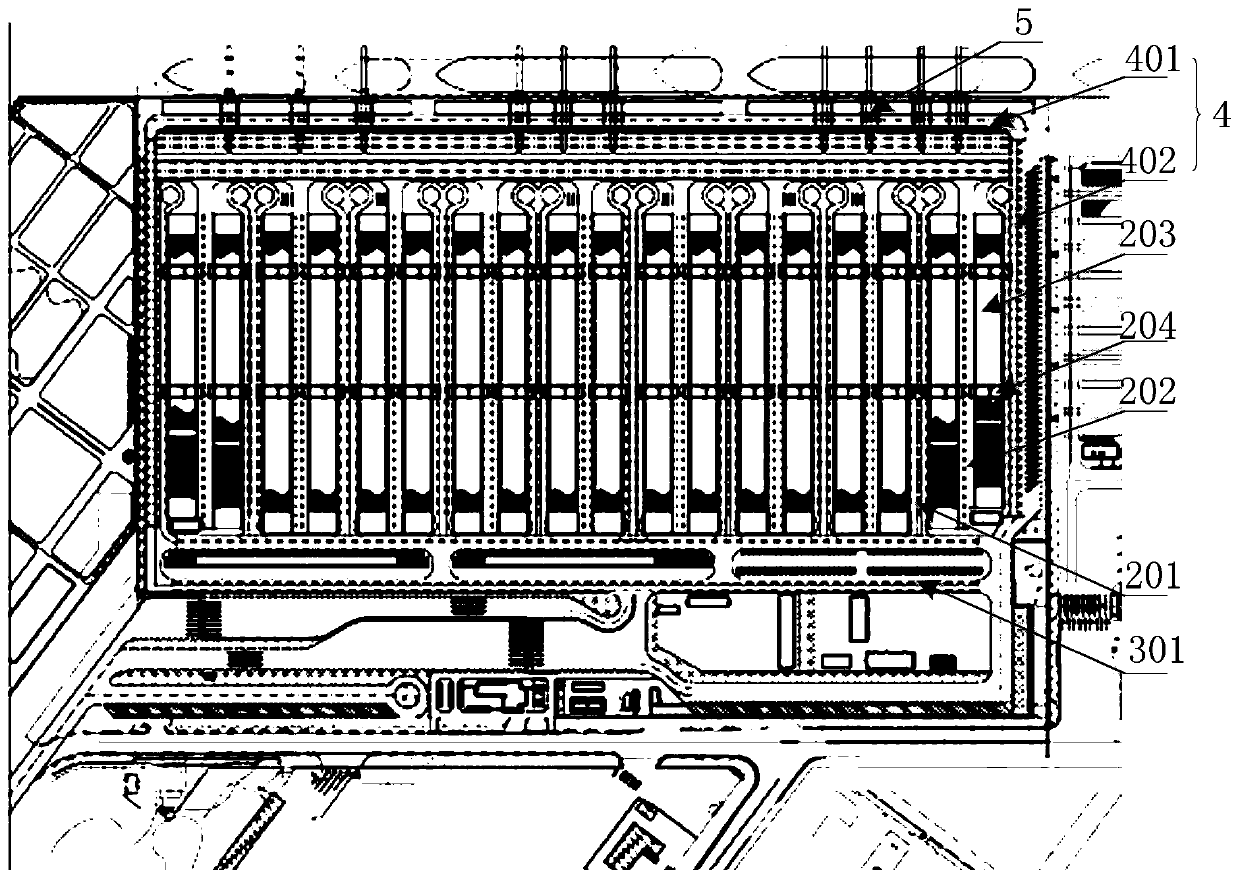

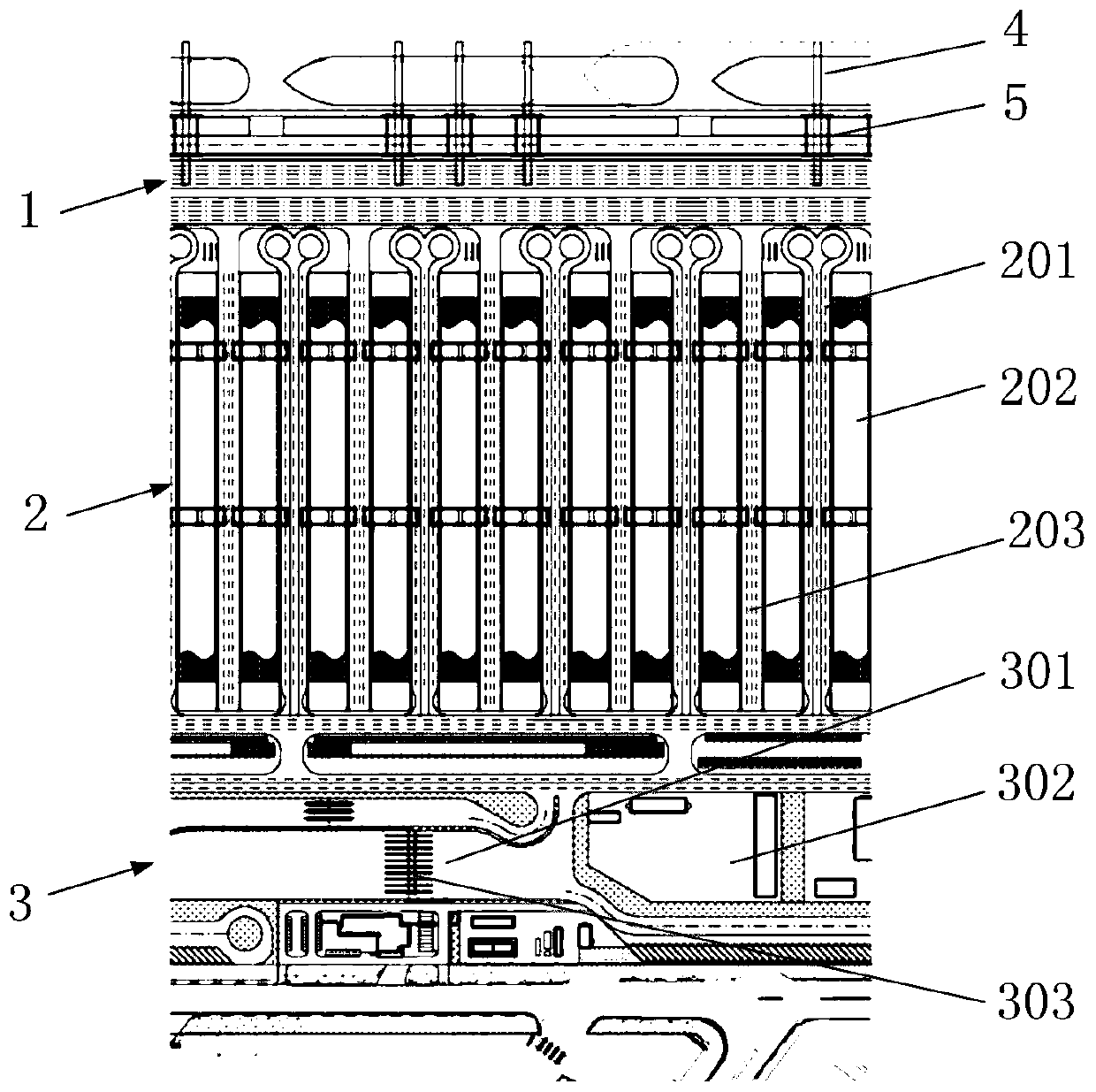

[0024] Such as figure 1 As shown, a container yard conveying system includes a plurality of container transport vehicle circulation channels 201 and automatic guided vehicle circulation transport channels 202 arranged in the yard and perpendicular to the extension direction of the shoreline, and a plurality of container transport vehicles circulate The transport channel 201 and multiple automatic guided vehicle circulation transport channels 202 are arranged at intervals and alternately, and the yard is divided into a plurality of container stacking blocks 203 in a vertical layout, even if the containers in the stacking yard are in the container stacking block 203 The interior is arranged in a vertical manner; among them,

[0025] In each container stacking block 203, the interval frame is provided with two double cantilever automatic channel cranes 204, which run along the vertical direction, so that the target container can complete the transportation and stacking of the con...

Embodiment 2

[0030] A container yard conveying system, the specific structure of which is basically the same as that of Embodiment 1, the difference is that: each of the two adjacent vertical rails that constitute each container transport vehicle circulation transport channel 201 is provided with a A vehicle steering device, the vehicle steering device is provided with a vehicle parking status indicator, so that after driving from a vertical road into a specific position marked on the vehicle steering device, the vehicle steering device rotates, and the container transport vehicle The vehicle head is turned to the container transport vehicle by the vehicle steering device and directly continues to drive into the vertical road on the adjacent side of the container. Wherein, since the vehicle length of the container transport vehicle is longer and the turning radius is larger, the use of the vehicle steering device to replace the curved track in Embodiment 1 can further reduce the floor space...

Embodiment 3

[0032] Such as figure 1 As shown, the terminal container conveying system includes an inner conveying section 1, a container yard conveying system arranged in the yard, and an outer conveying section 3; wherein,

[0033] The inner conveying section 1 is a horizontal operation section located between the wharf and the storage yard. In the inner conveying section 1, there is an automatic guided vehicle passage adapted to the automatic guided vehicle circulation passage 202 laid on the inner conveying section 1. The automatic guided vehicle channel enables multiple automatic guided vehicles to transport containers between the quay crane and the yard. Specifically, the automatic guided vehicle drives to the designated quay crane, loads the container and transports it to the designated container stack in the yard at the loading and unloading position of the block, and then stack the container to the designated position with the cooperation of the double-cantilever automatic channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com