Laser additive manufacturing method for synergistically improving surface precision and strength of titanium alloy

A laser additive and surface precision technology, applied in the field of laser additive manufacturing and laser-powder coupling, which can synergistically improve the surface precision and strength of titanium alloys, can solve the problems of increased cycle and cost, high cost, and difficulty in speeding up, and achieve organizational Controllable, synergistic improvement of surface precision and strength, and high surface precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Specific steps are as follows:

[0035] (1) The Ti6Al4V alloy powder within the particle size range of 15-50 μm is evenly loaded into the laser powder bed additive manufacturing powder feeder, with consistent quality, dryness and no agglomeration;

[0036] (2) Level the substrate of the forming cabin of the powder bed equipment, rush into the argon protection, the outlet pressure of the argon protection gas is 1-6KPa, and reduce the oxygen content in the cabin to below 100ppm;

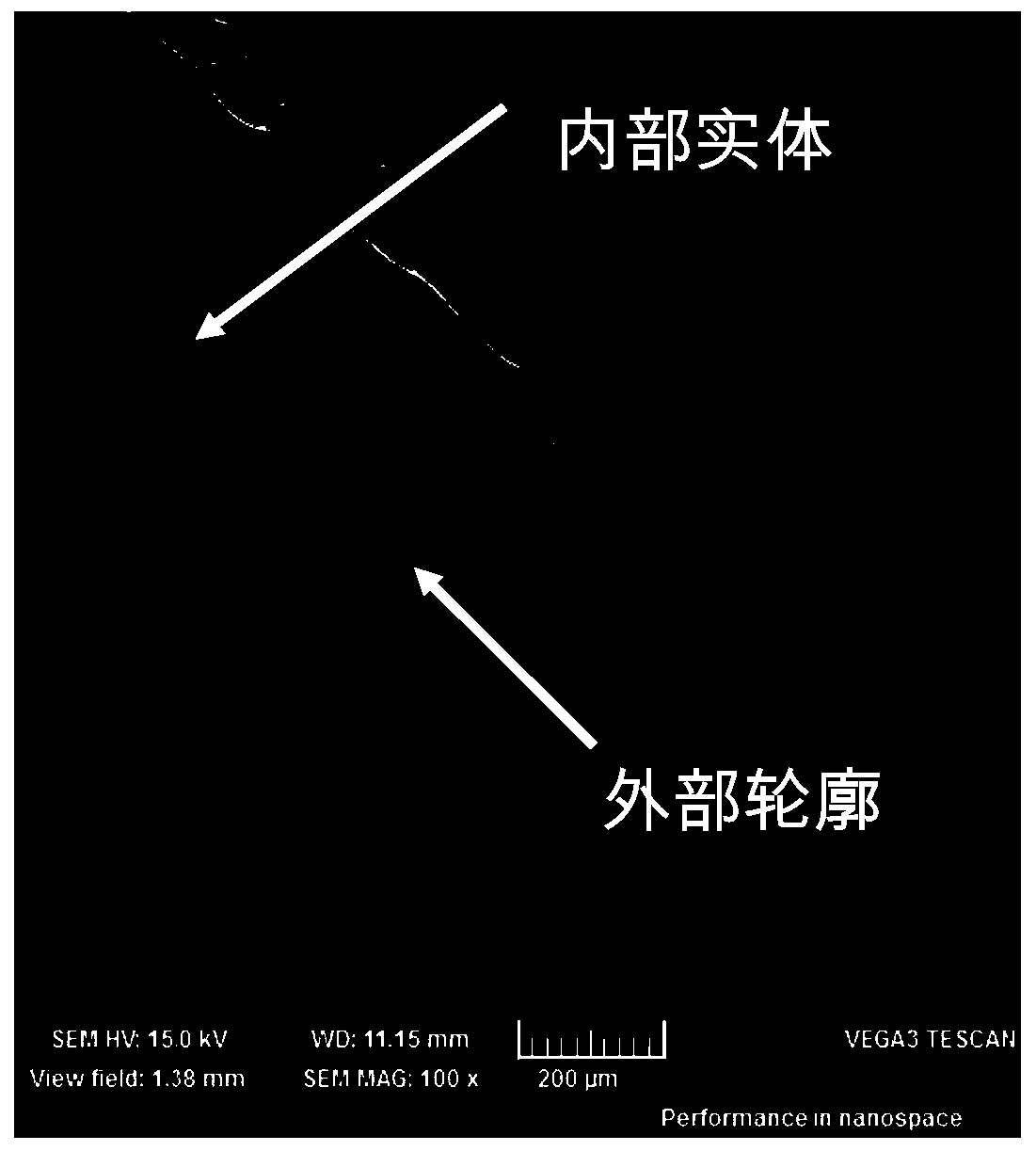

[0037] (3) The Ti6Al4V alloy powder is evenly and continuously pre-laid on the forming substrate, and the parameters of the laser power 280W, scanning speed 1100mm / s, spot size 100μm, scanning distance 80μm, and powder coating thickness 30μm are used to print the internal entity of the test piece forming;

[0038] (4) Use the parameters of laser power 150W, scanning speed 1300mm / s, spot size 100μm, and powder coating thickness 30μm to print the outer contour of the specimen, and the thickness o...

Embodiment 2

[0041] Specific steps are as follows:

[0042] (1) The Ti6Al4V alloy powder within the particle size range of 15-50 μm is evenly loaded into the laser powder bed additive manufacturing powder feeder, with consistent quality, dryness and no agglomeration;

[0043] (2) Level the substrate of the forming cabin of the powder bed equipment, rush into the argon protection, the outlet pressure of the argon protection gas is 1-6KPa, and reduce the oxygen content in the cabin to below 100ppm;

[0044] (3) The Ti6Al4V alloy powder is evenly and continuously pre-laid on the forming substrate, and the parameters of the laser power 250W, scanning speed 1100mm / s, spot size 100μm, scanning distance 80μm, and powder coating thickness 30μm are used to print the internal entity of the test piece forming;

[0045] (4) Use the parameters of laser power 150W, scanning speed 1500mm / s, spot size 100μm, and powder coating thickness 30μm to print the outer contour of the specimen, and the thickness of ...

Embodiment 3

[0048] Specific steps are as follows:

[0049] (1) The Ti6Al4V alloy powder within the particle size range of 15-50 μm is evenly loaded into the laser powder bed additive manufacturing powder feeder, with consistent quality, dryness and no agglomeration;

[0050] (2) Level the substrate of the forming cabin of the powder bed equipment, rush into the argon protection, the outlet pressure of the argon protection gas is 1-6KPa, and reduce the oxygen content in the cabin to below 100ppm;

[0051] (3) The Ti6Al4V alloy powder is evenly and continuously pre-laid on the forming substrate, and the parameters of the laser power 350W, scanning speed 500mm / s, spot size 90μm, scanning distance 60μm, and powder coating thickness 30μm are used to print the internal entity of the test piece forming;

[0052] (4) Use the parameters of laser power 90W, scanning speed 1000mm / s, spot size 90μm, and powder coating thickness 30μm to print the outer contour of the specimen. The thickness of the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com