Carbon nanosheet layer loaded TiO2 molecular imprinting material as well as preparation method and application thereof

A molecular imprinting, carbon nanosheet technology, applied in chemical instruments and methods, ion exchange, other chemical processes, etc., can solve the problem of no selective-adsorption-photocatalysis strong coupling, low product concentration pollutant degradation effect is low and other problems, to achieve the effect of obvious adsorption-photocatalytic synergy, efficient selective recognition and degradation, strong adsorption and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

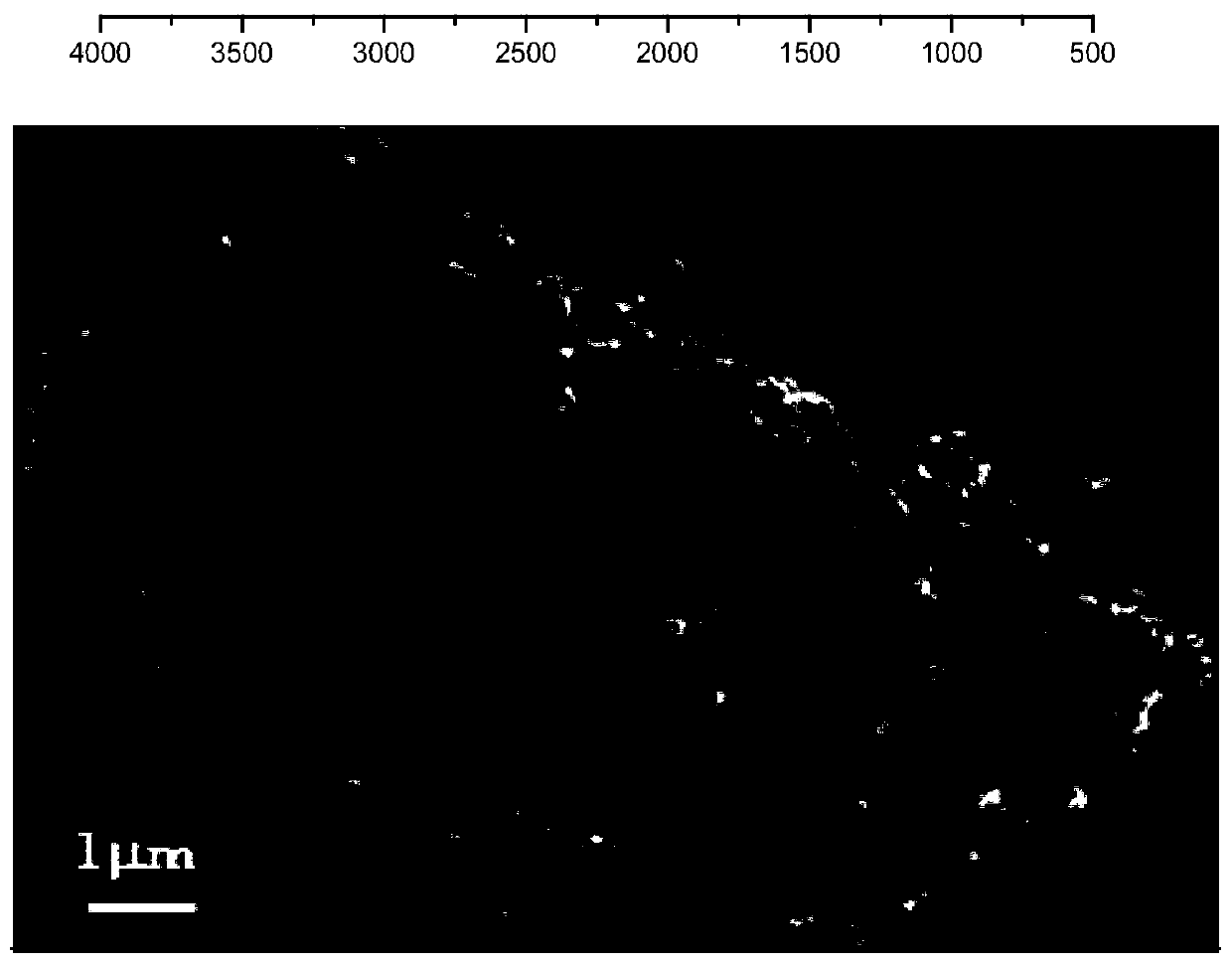

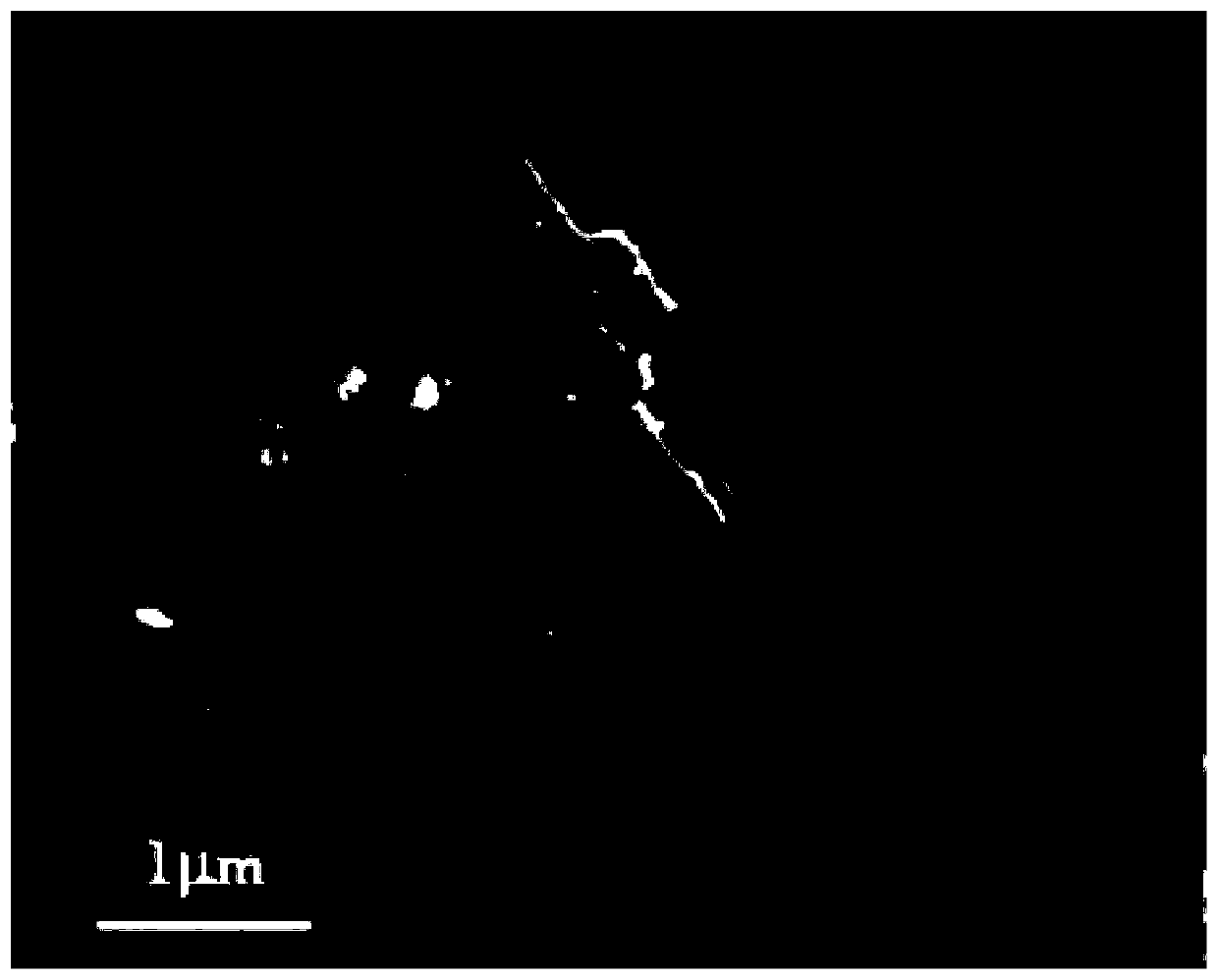

Image

Examples

Embodiment 1

[0057] A carbon nanosheet supported TiO 2 A method for preparing a molecularly imprinted material, comprising the following steps:

[0058] (1) Dissolve F127 in water and absolute ethanol with a volume ratio of 1:1 at room temperature and constant stirring, and control its mass concentration to 0.06%. After the reagent is completely dissolved, add resorcinol in sequence , concentrated hydrochloric acid and formaldehyde solution, the control resorcinol and formaldehyde molar ratio is 1:2, the pH of solution is 1.5, obtains solution A; The mass ratio of F127 and hydroquinone is 1:1;

[0059] (2) Under the condition of room temperature and continuous stirring, put the titanium trichloride solution (containing 3wt% hydrochloric acid) with a concentration of 0.5mol / L in water, control its volume ratio to 1:1, stir for a period of time and then Add sodium nitrate and sodium sulfate, and control the volume ratios of their mass and titanium trichloride aqueous solution to 1:80g / mL an...

Embodiment 2

[0069] As described in Example 1, the difference is:

[0070] In step (6), the substance ratio of control template: functional monomer: crosslinking agent is 1:2:5. On this basis, the mass ratio of the matrix to the imprinted polymer (functional monomer + crosslinking agent) is controlled to be 1:2;

[0071]In step (7), the polymerization reaction was carried out in a water bath at 50° C. for 30 hours. Cool to room temperature, centrifuge, wash three times with ethanol and distilled water respectively, then add 300mL distilled water, place under 600W ultraviolet light for 1 hour to remove the template.

Embodiment 3

[0073] As described in Example 1, the difference is:

[0074] In step (6), the substance ratio of control template: functional monomer: crosslinking agent is 1:6:15. On this basis, the mass ratio of the matrix to the imprinted polymer (functional monomer + crosslinking agent) is controlled to be 1:8;

[0075] In step (7), the polymerization reaction was carried out in a water bath at 90° C. for 15 hours. Cool to room temperature, centrifuge, wash three times with ethanol and distilled water respectively, then add 300mL distilled water, place under 200W ultraviolet light for 5 hours to remove the template.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com