Natural antibacterial gauze and preparation method and application thereof

A natural antibacterial and gauze technology, applied in the medical field, can solve the problems of cumbersome preparation and high preparation cost, and achieve the effects of simplifying the process, good moisturizing performance, and promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

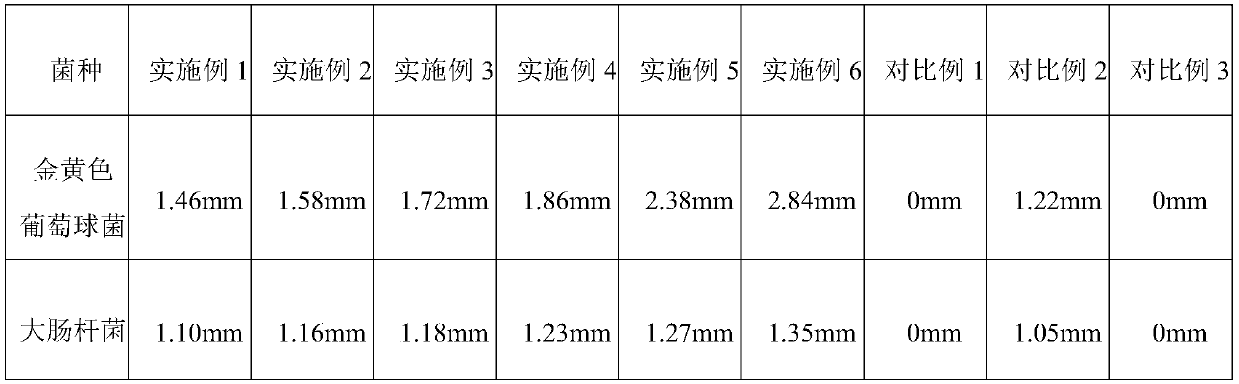

Examples

Embodiment 1

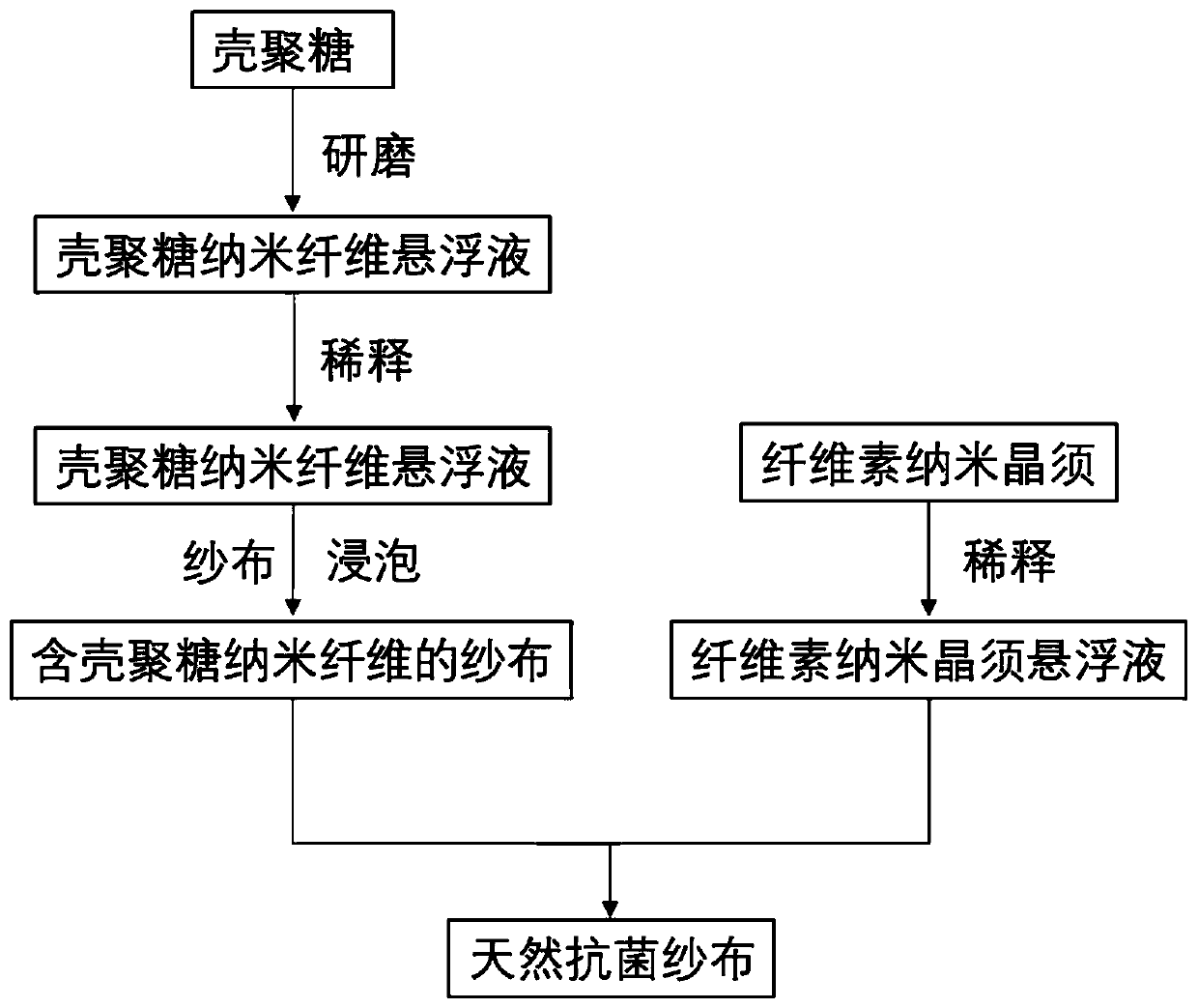

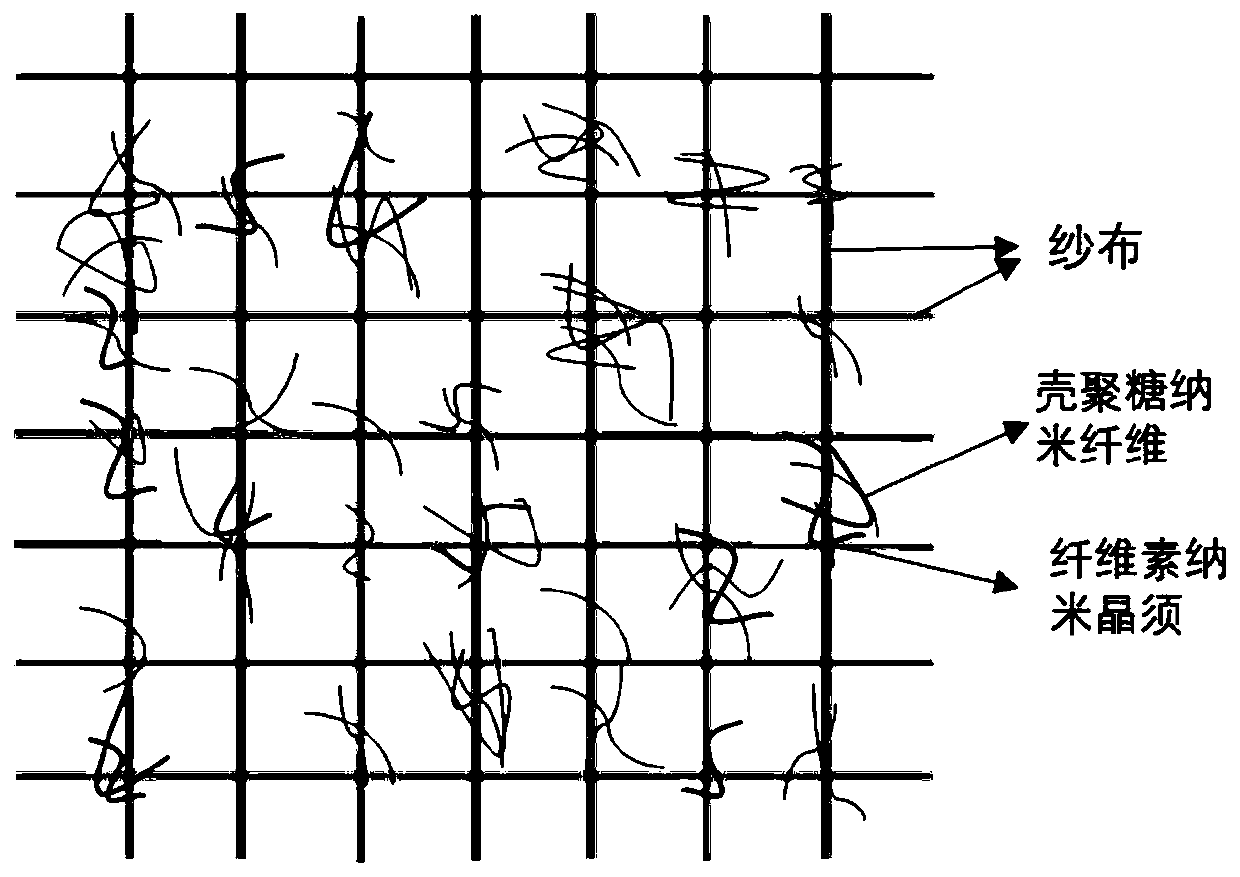

[0039] A kind of preparation method of natural antibacterial gauze is as follows (its preparation process is as follows: figure 1 As shown, the schematic diagram of the structure is shown in figure 2 shown):

[0040] (1) Add chitosan into a 1000ml beaker filled with deionized water, and disperse evenly with an electric stirrer. % suspension; Utilize the single-platform planetary ball mill to grind, the grinding time is 3h, the rotating speed is 320rpm, the mass ratio of dry chitosan and agate beads is 1:60, and the mass fraction 1% chitosan nanofiber is obtained; Chitosan nanofibers and cellulose nano whiskers were diluted respectively (adding deionized water), and the dilution conditions were as follows: the rotating speed was 800rpm, the temperature was 25°C, and the time was 20min to obtain shells with a mass fraction of 0.5% respectively. The polysaccharide nanofiber suspension and the cellulose nanowhisker suspension with a mass fraction of 1%;

[0041] (2) soaking pu...

Embodiment 2

[0044] A kind of preparation method of natural antibacterial gauze is as follows:

[0045](1) Add chitosan into a 1000ml beaker filled with deionized water, and disperse evenly with an electric stirrer. % suspension, utilize single-platform planetary ball mill to grind, grinding time is 4h, rotating speed is 350rpm, the mass ratio of dry chitosan and agate beads is 1:60, obtains mass fraction 1% chitosan nanofiber; Chitosan nanofibers and cellulose nanowhiskers were diluted respectively, and the dilution conditions were as follows: the rotating speed was 800rpm, the temperature was 25°C, and the time was 30min to obtain a suspension of chitosan nanofibers with a mass fraction of 0.8%. And mass fraction is the cellulose nano whisker suspension of 1%;

[0046] (2) soaking pure cotton gauze in the chitosan nanofiber suspension of 0.8% by mass fraction for 20min, then taking out the pure cotton gauze and putting it into the temperature is 60 ℃ for drying to obtain chitosan nanofi...

Embodiment 3

[0049] A kind of preparation method of natural antibacterial gauze is as follows:

[0050] (1) Add chitosan into a 1000ml beaker filled with deionized water, and disperse evenly with an electric stirrer. % suspension, utilize single platform planetary ball mill to grind, grinding time is 5h, rotating speed is 380rpm, the mass ratio of dry chitosan and agate beads is 1:60, obtains mass fraction 1% chitosan nanofiber; Dilute chitosan nanofibers and cellulose nanowhiskers respectively, and the dilution conditions are as follows: the rotating speed is 800rpm, the temperature is 25°C, and the time is 40min to obtain a suspension of chitosan nanofibers with a mass fraction of 0.8%. And mass fraction is the cellulose nano whisker suspension of 0.8%;

[0051] (2) soaking pure cotton gauze in the chitosan nanofiber suspension of 0.8% by mass fraction for 20min, then taking out the pure cotton gauze and putting it into temperature is 80 ℃ for drying to obtain the chitosan nanofiber con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com