Air-permeable flexible putty for buildings and preparation method thereof

A breathable and flexible technology, applied in the field of building materials, can solve problems such as protective layer swelling, system instability, condensation, etc., and achieve good air permeability, excellent comprehensive mechanical properties, and strong air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

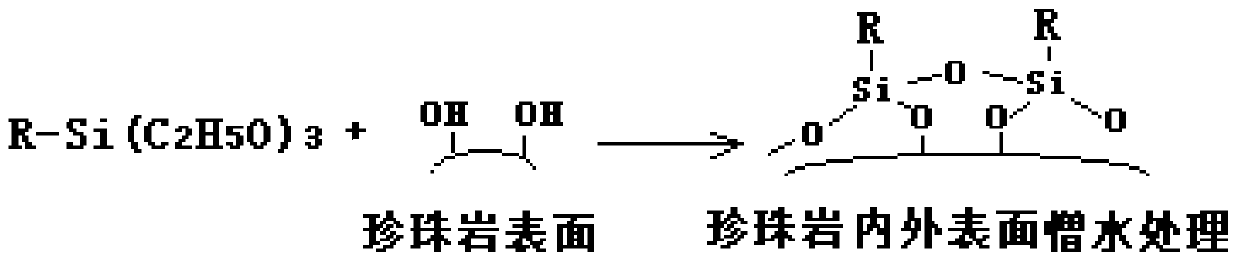

[0037] A construction breathable flexible putty, the preparation process of which is as follows:

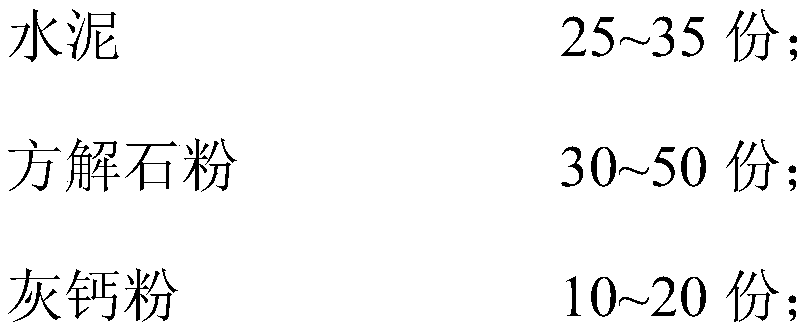

[0038] (1) Atomize 0.084 parts of n-octyltriethoxysilane water repellent, spray on 6 parts of expanded perlite, stir (50-60r / min) at 50-60°C, mix thoroughly for 1.5h, and leave at room temperature Stand for 24 hours and set aside; (2) Mix 28 parts of P.O52.5# ordinary Portland cement, 43 parts of calcite powder, 16.4 parts of lime calcium powder, 0.24 parts of calcium stearate, 5.5 parts of ethylene-vinyl acetate latex powder, Add 0.26 parts of hydroxymethylpropyl cellulose, 0.016 parts of sodium dodecylbenzene sulfonate, and 0.5 parts of melamine superplasticizer into the stirring equipment, stir thoroughly at 50-60 r / min for 2.2 hours, and then add step (1) The putty of the present invention can be obtained by stirring the treated expanded perlite at a slow speed of 30-40r / min for 1.2h.

Embodiment 2

[0040] A construction breathable flexible putty, the preparation process of which is as follows:

[0041](1) Atomize 0.128 parts of n-octyltrimethoxysilane water repellent, spray on 6 parts of expanded perlite, stir (50-60r / min) at 50-60°C, mix thoroughly for 1.6h, and place at room temperature Standby after 24 hours; (2) Mix 32 parts of P.O42.5# ordinary portland cement, 41 parts of calcite powder, 14 parts of lime calcium powder, 0.31 parts of calcium stearate, 6.1 parts of acrylic latex powder, 0.30 parts of hydroxyethyl Base cellulose, 0.012 parts of sodium dodecylbenzene sulfonate, and 0.15 parts of acrylic acid superplasticizer are added to the stirring equipment, and after 50-60r / min full stirring for 2.3 hours, then add the expanded perlite treated in step (1), Stir at a slow speed of 30-40r / min for 1.5h to obtain the putty of the present invention.

Embodiment 3

[0043] A construction breathable flexible putty, the preparation process of which is as follows:

[0044] (1) Atomize 0.182 parts of n-octyltriethoxysilane water-repellent, spray on 7.9 parts of expanded perlite, stir (50-60r / min) at 50-60°C, mix well for 1.5h, and leave at room temperature After standing for 24 hours, it is ready for use; (2) 34 parts of white Portland cement, 37 parts of calcite powder, 12 parts of lime calcium powder, 0.35 part of calcium stearate, 7.8 parts of ethylene-vinyl acetate latex powder, 0.22 part of hydroxymethylpropane Base cellulose, 0.018 parts of sodium dodecylbenzene sulfonate, and 0.53 parts of naphthalene-based water reducer are added to the stirring equipment, and after fully stirring at 50-60r / min for 2.5 hours, then add the expanded perlite treated in step (1) , 30 ~ 40r / min slow stirring 1.5h can get the putty of the present invention.

[0045] Performance Testing:

[0046] The general physical properties are tested according to JG / T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com