3D (three-dimensional) printer silk material conveying mechanism and silk feeding method thereof

A technology of 3D printer and transmission mechanism, applied in the direction of 3D object support structure, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable printing, silk discharge, printing failure, etc., to achieve long service life and smooth silk discharge. , the effect of reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

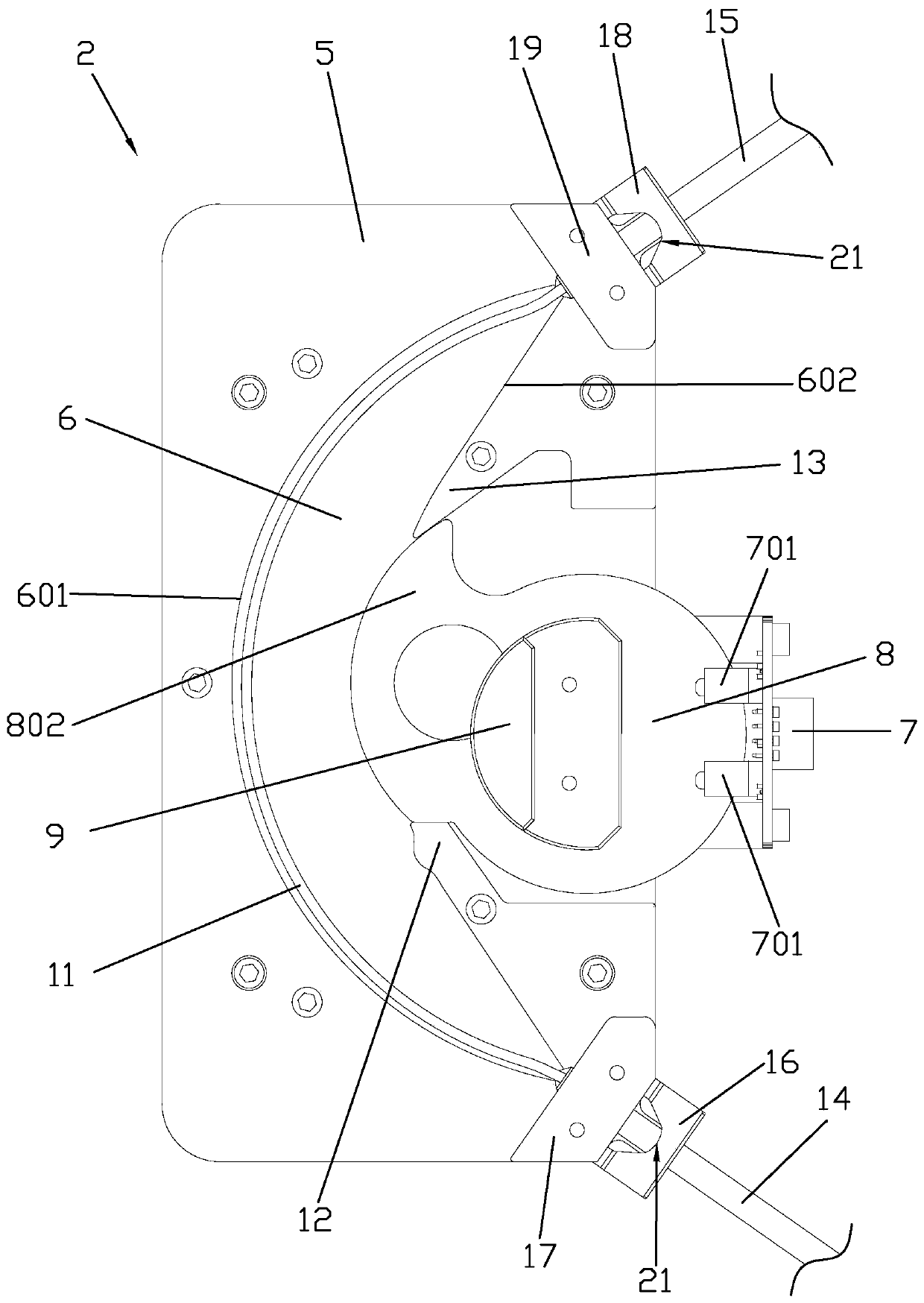

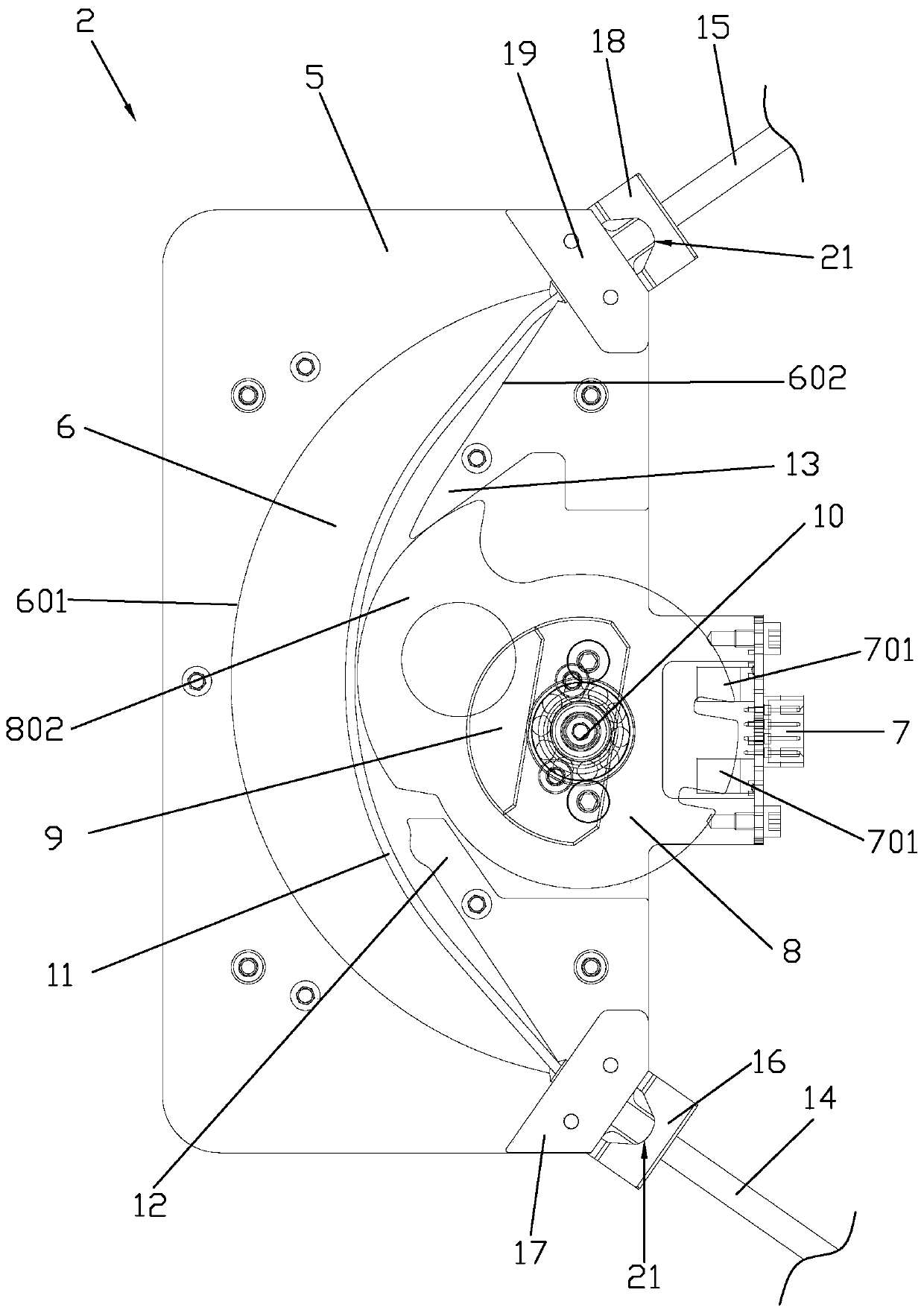

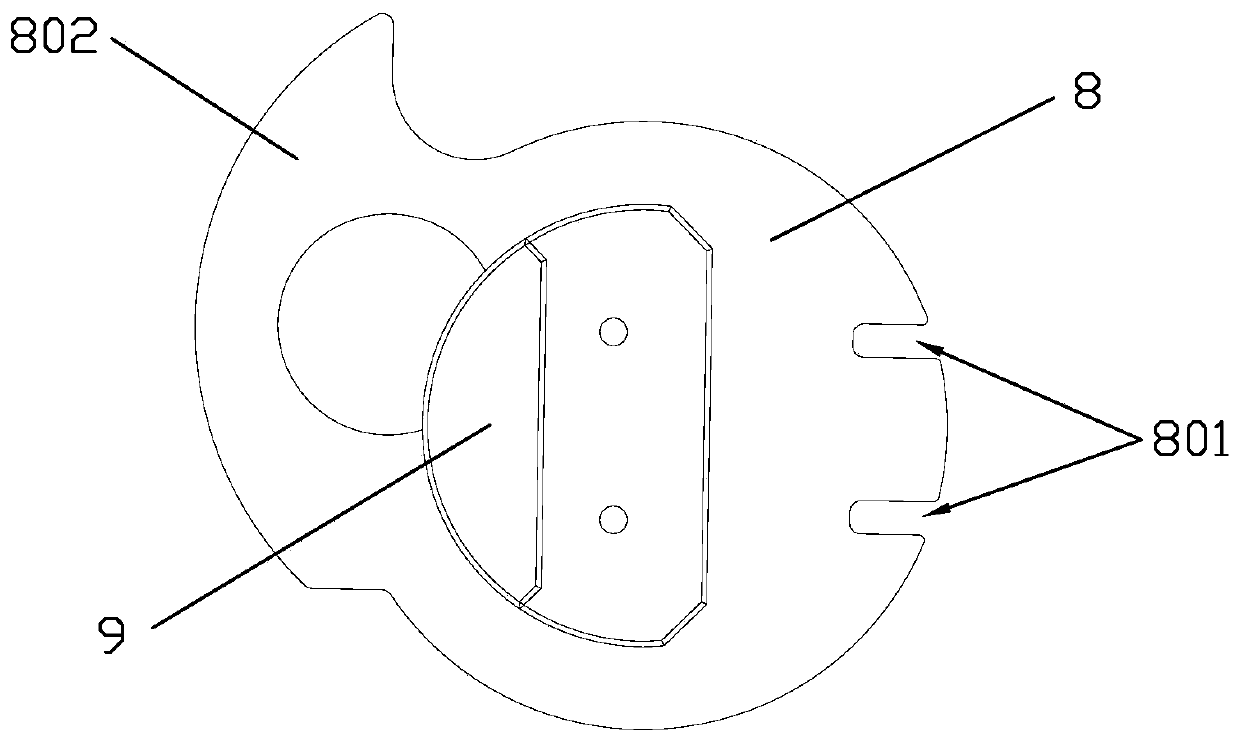

[0042] Such as Figure 1 to Figure 6 A 3D printer wire transmission mechanism shown includes a wire pushing device 3 , a wire pulling device (not shown in the figure), a main board (not shown in the figure) and a wire buffer device 2 . The wire material pushing device 3 is installed outside the wire material box 23, and the wire material pulling device is installed in the printer nozzle 4, the wire material box 3 is at the bottom of the printer body 5, and the printer nozzle 4 is at the top of the printer body 5. The silk buffer device 2 includes a bottom plate 5, and the bottom plate 5 is provided with a wire inlet, a feeding channel 6, a wire outlet, an eccentric structure and a photoelectric sensor 7. The feeding channel 6 is crescent-shaped, and the feeding channel 6 is provided with an outer ring 601 and an inner ring 602 , and the inner ring 602 is provided with an inner ring opening 603 . The eccentric structure includes a turntable 8 , an eccentric wheel 9 and a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com