Low-temperature vanadium-titanium-based SCR denitrification catalyst and preparation method thereof

A denitration catalyst, vanadium-titanium-based technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc. The effect of oxygen capacity, good denitration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

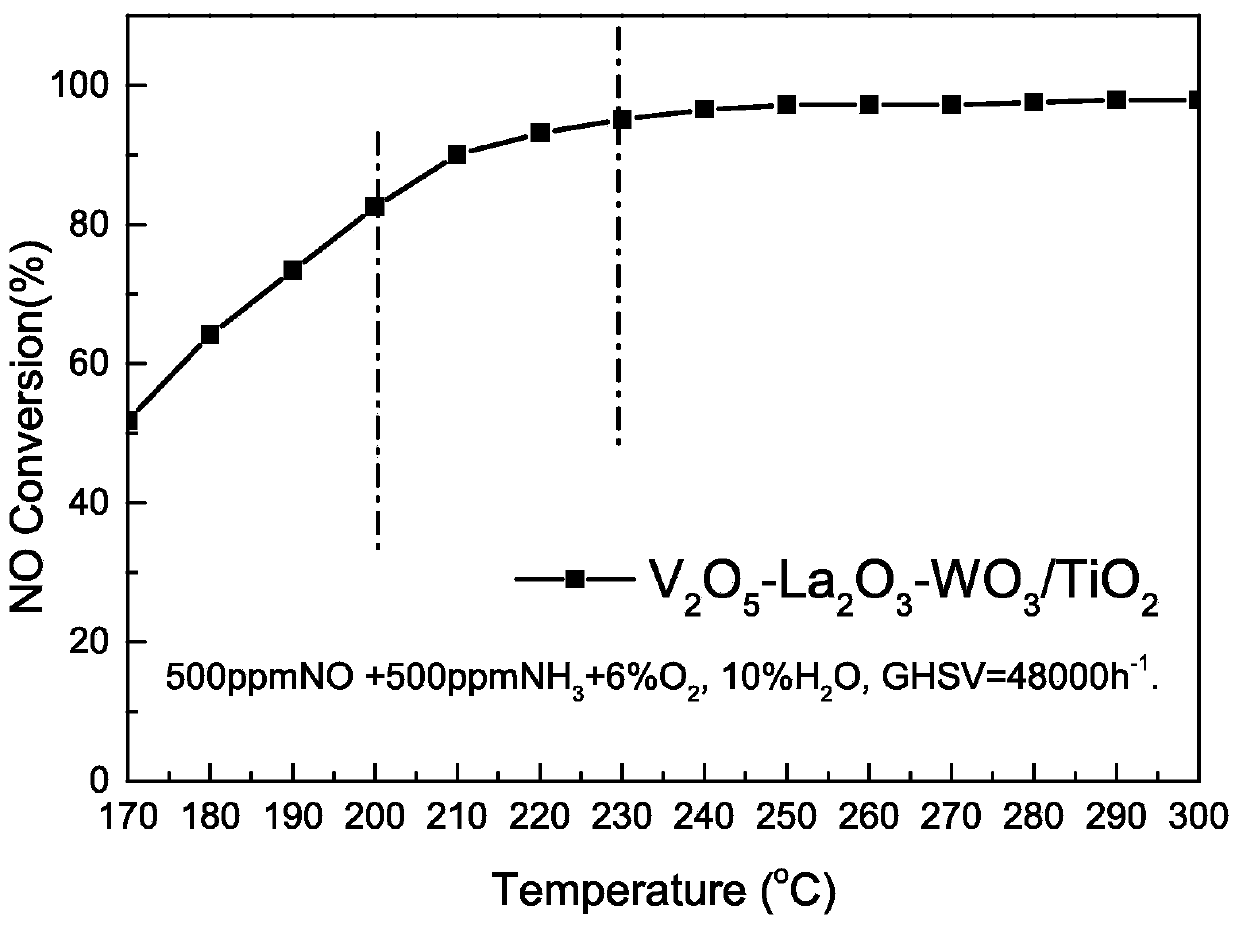

[0024] Prepare 4% V by impregnation 2 o 5 -4% La 2 o 3 -3% WO 3 / TiO 2 (mass ratio) catalyst and used for industrial flue gas SCR denitrification. The specific implementation steps are as follows:

[0025] Weigh 0.256g ammonium metavanadate, 0.184g lanthanum oxide, 0.148g ammonium metatungstate, dissolve and mix uniformly to obtain a precursor solution; 4.30g anatase TiO 2 The carrier was immersed in the above metal precursor solution, mixed evenly, and dried at 110°C for 10 hours to obtain catalyst powder. The catalyst powder was calcined at 550°C for 2 hours to obtain 4% V 2 o 5 -4% La 2 o 3 -3% WO 3 / TiO 2 Low temperature SCR denitrification catalyst.

[0026] 4% V prepared by the above method 2 o 5 -4% La 2 o 3 -3% WO 3 / TiO 2 The catalyst is placed in a fixed bed reactor, and the reaction gas composition is (volume ratio) 500ppm NO, 500ppm NH 3 , 100ppm SO 2 , 6%O 2 , 10%H 2 O, N 2 As the carrier gas, the space velocity (GHSV) is 48000h -1 . The ...

Embodiment 2

[0028] Prepare 3% V by impregnation 2 o 5 -4%Sc 2 o 3 -8%MoO 3 / TiO 2 (mass ratio) catalyst and used for industrial flue gas SCR denitrification. The specific implementation steps are as follows:

[0029] Weigh 0.205g ammonium metavanadate, 0.710g scandium nitrate, 0.520g ammonium paratungstate, dissolve and mix uniformly to obtain a precursor solution; 4.30g anatase TiO 2 The carrier is immersed in the above metal precursor solution, mixed evenly, and dried at 100° C. for 12 hours to obtain a powder. The powder was calcined at 450°C for 5 hours to obtain 3% V 2 o 5 -4%Sc 2 o 3 -8%MoO 3 / TiO2 Low temperature SCR denitrification catalyst.

[0030] 3% V prepared by the above method 2 o 5 -4%Sc 2 o 3 -8%MoO 3 / TiO 2 The catalyst is placed in a fixed bed reactor, and the reaction gas composition is (volume ratio) 1000ppmNO, 1000ppmNH 3 , 800ppm SO 2 , 3%O 2 , 10%H 2 O, N 2 As the carrier gas, the space velocity (GHSV) is 48000h -1 . The catalyst is NO at 1...

Embodiment 3

[0032] Prepare 3% V by impregnation 2 o 5 -7%CeO 2 -7% WO 3 / TiO 2 (mass ratio) catalyst and used for SCR denitrification of industrial flue gas. The specific implementation steps are as follows:

[0033] Weigh 0.191g ammonium metavanadate, 0.878g cerium nitrate, 0.372g ammonium metatungstate, dissolve and mix uniformly to obtain a precursor solution; 4.30g anatase TiO 2 The carrier was immersed in the above metal precursor solution, mixed evenly, and dried at 100°C for 8 hours to obtain a powder. The powder was calcined at 500°C for 4 hours to obtain 3% V 2 o 5 -7%CeO 2 -7% WO 3 / TiO 2 Low temperature SCR denitrification catalyst.

[0034] 3% V prepared by the above method 2 o 5 -7%CeO 2 -7% WO 3 / TiO 2 The catalyst is placed in a fixed bed reactor, and the reaction gas composition is (volume ratio) 600ppm NO, 600ppm NH 3 , 200ppm SO 2 , 4%O 2 , 10%H 2 O, N 2 As the carrier gas, the space velocity (GHSV) is 42000h -1 . Experiments show that the catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com