Ceramic ball sphere surface defect detection system

A detection system and surface defect technology, applied in the field of non-contact ceramic sphere surface defect detection system, can solve the problems of easy eye irritation, difficulty in ensuring accuracy, and inability to guarantee the sphere to be tested, etc., and achieve a controllable detection operation process, The mechanical structure is simple and reliable, and the working principle is simple and clear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

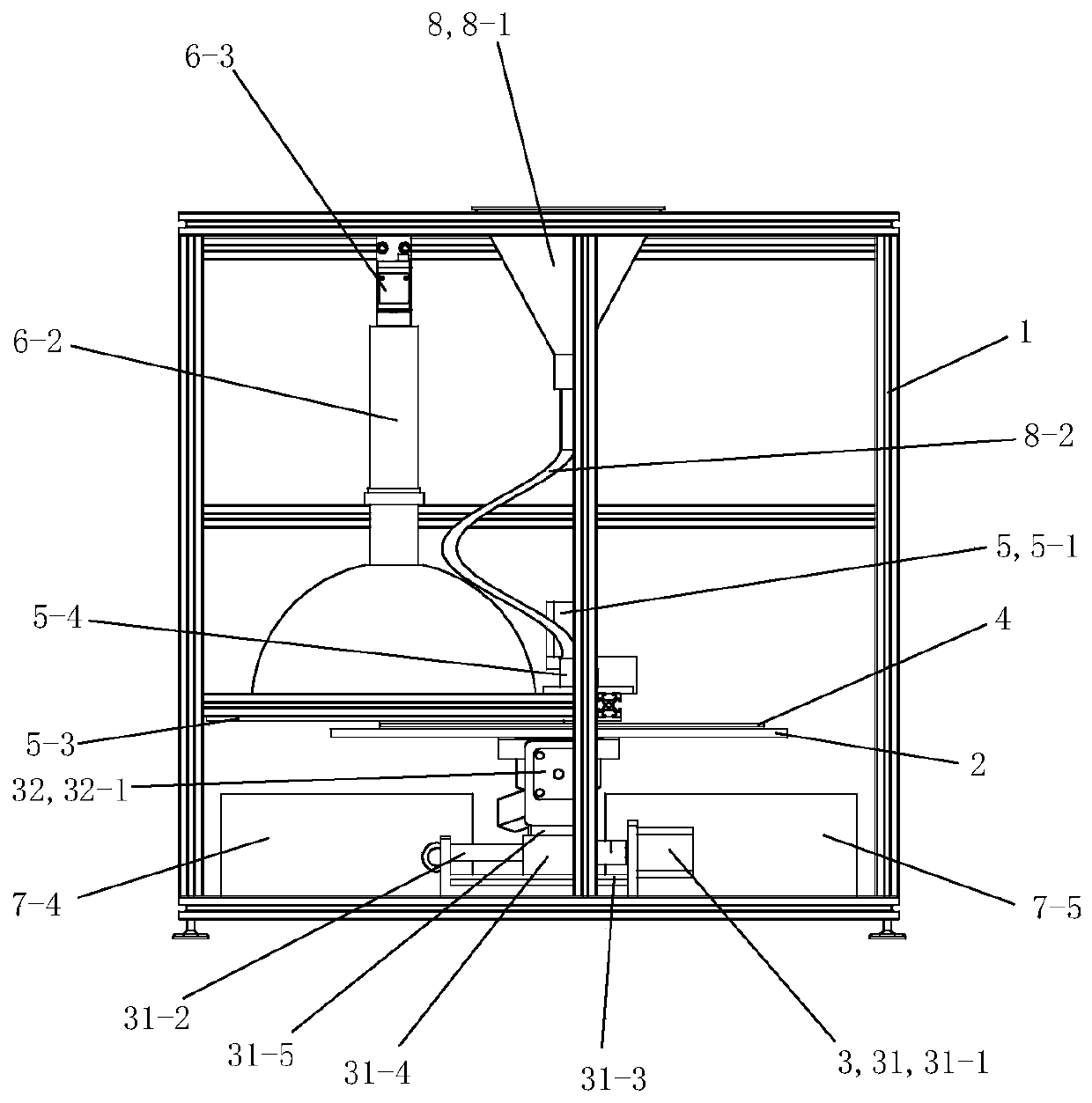

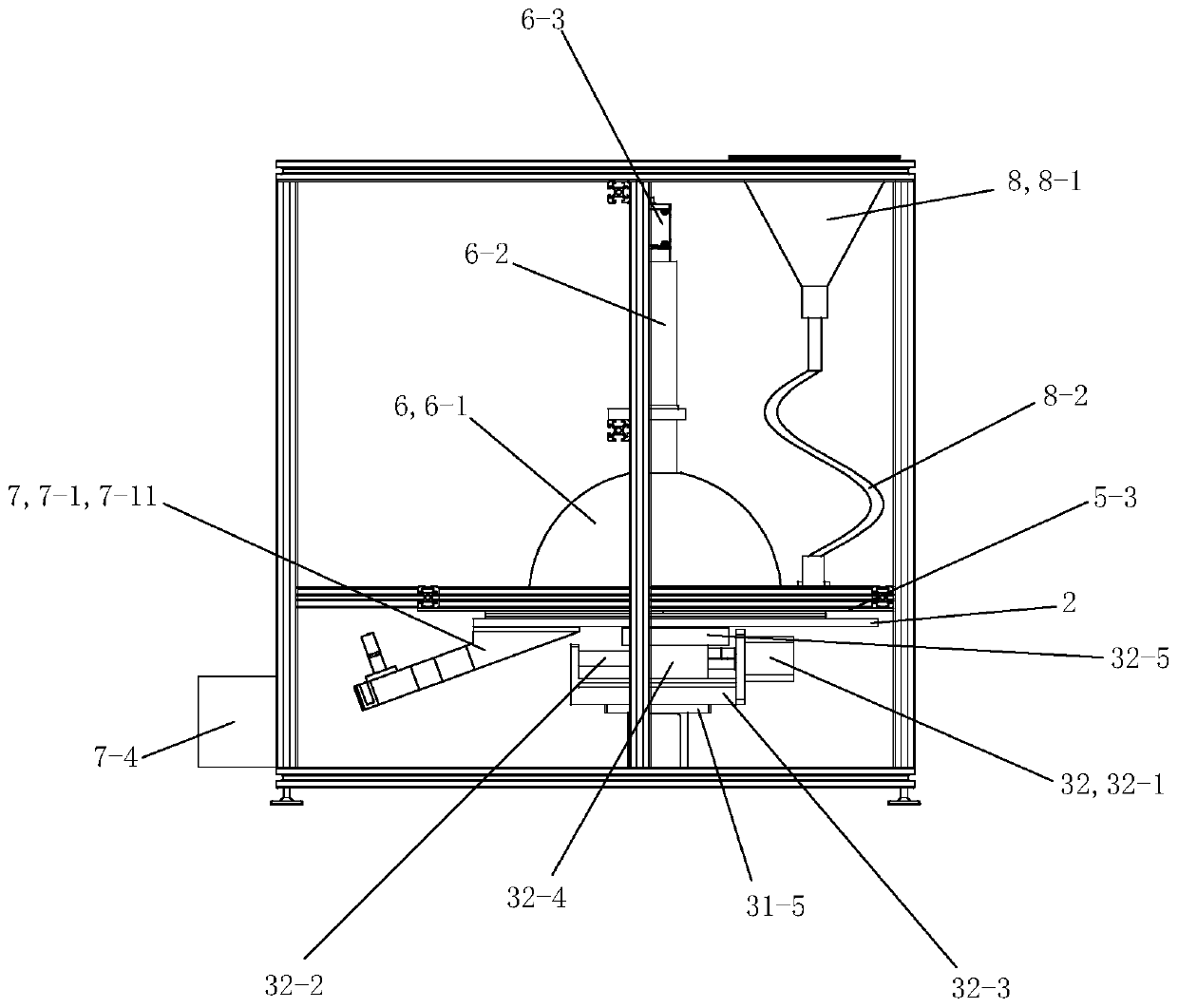

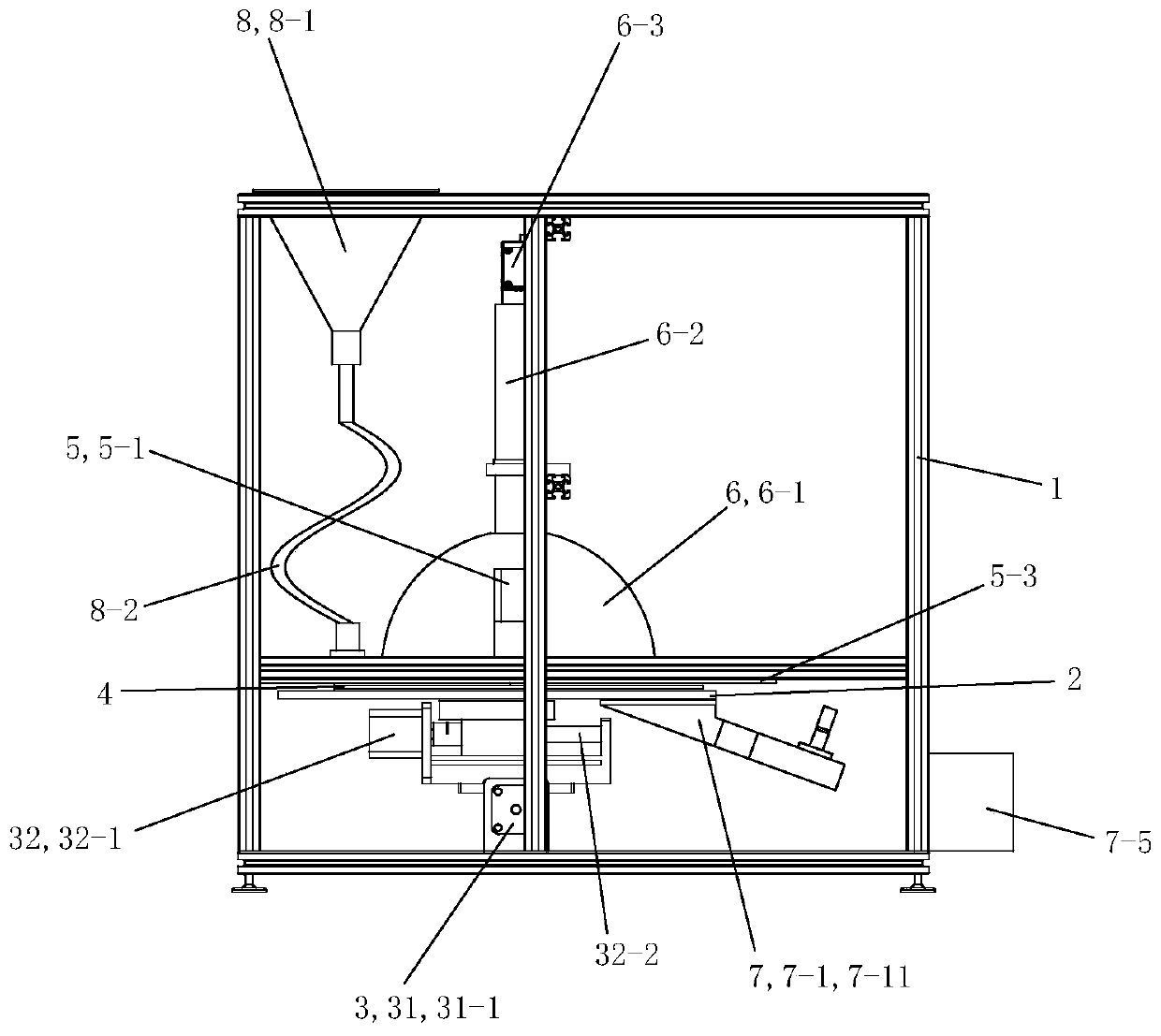

[0053] See Figure 1 to Figure 12 , The ceramic ball surface flaw detection system includes a frame 1, a friction disc 2, a friction disc drive mechanism 3, a sphere tray 4, a tray drive mechanism 5, a machine vision camera 6, a sphere sorting mechanism 7 and a feeding mechanism 8.

[0054] See Figure 1 to Figure 8 , the friction disc 2 is rectangular, and the surface of the friction disc 2 is made of polyurethane material. The rear portion of the friction disc 2 is provided with a blanking opening 2-1 that runs through its upper and lower openings and faces backward.

[0055] See Figure 1 to Figure 7 , The friction disc driving mechanism 3 includes an X-axis driving device 31 and a Y-axis driving device 32 .

[0056] See Figure 1 to Figure 7 , The X-axis driving device 31 includes an X-axis stepping motor 31-1, an X-axis screw rod 31-2, an X-axis slide rail 31-3, an X-axis slider 31-4 and an X-axis connecting seat 31-5.

[0057] The X-axis stepping motor 31-1 is fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com