A device for measuring the viscosity of high temperature coal ash

A measuring device and coal ash technology, applied in the field of coal gasification, can solve the problems of poor fluidity of ash and slag, unfavorable use of slag to resist slag to protect the furnace wall, etc., and achieve the effect of stable slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

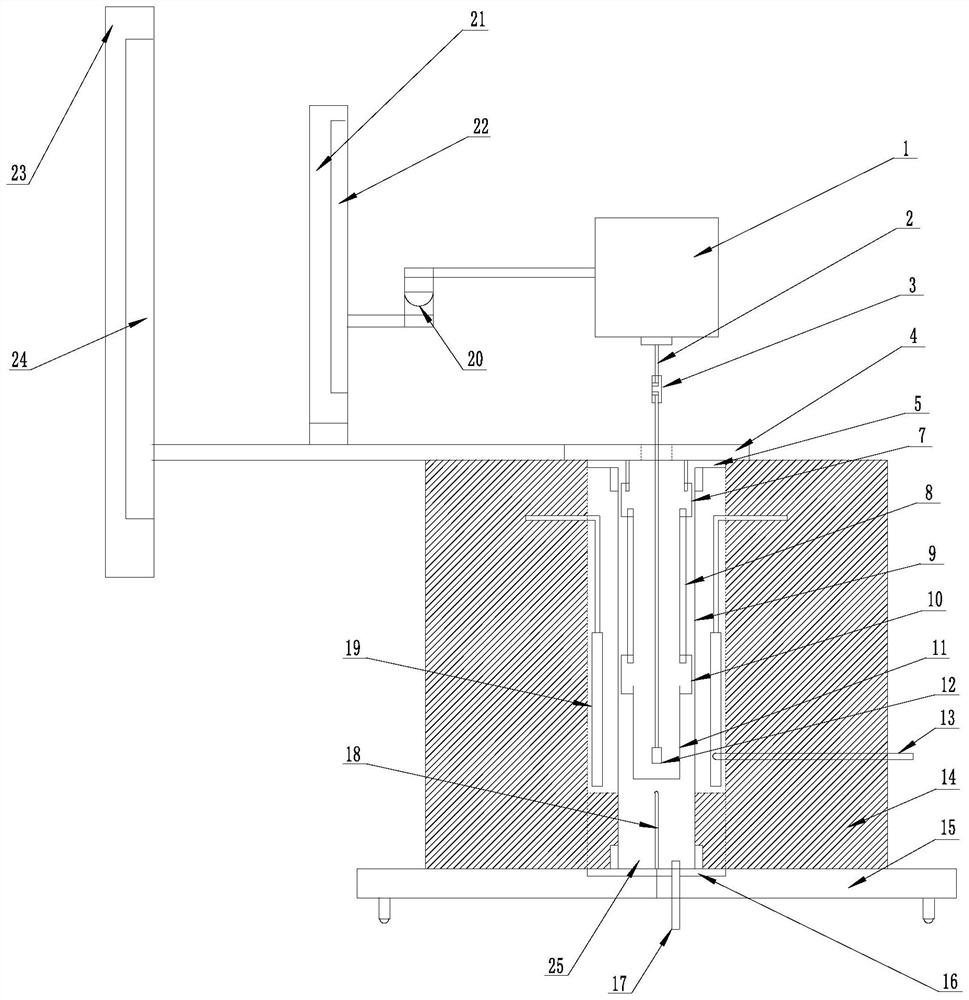

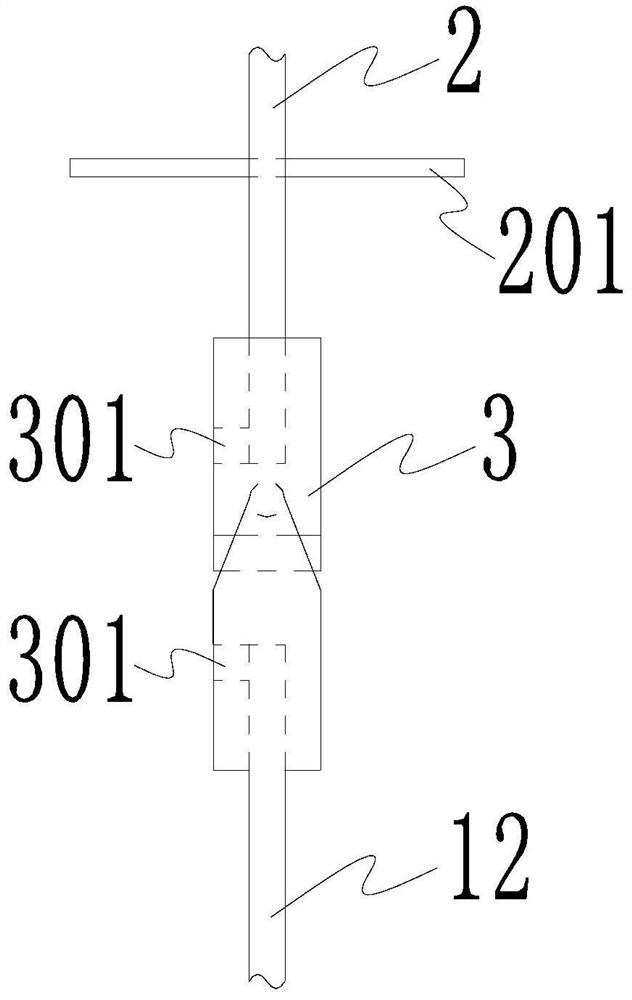

[0090] see Figure 1 to Figure 9 shown;

[0091] A device for measuring the viscosity of high-temperature coal ash of the present invention comprises:

[0092] main body;

[0093] The mobile bracket 15 integrated in the lower part of the main body;

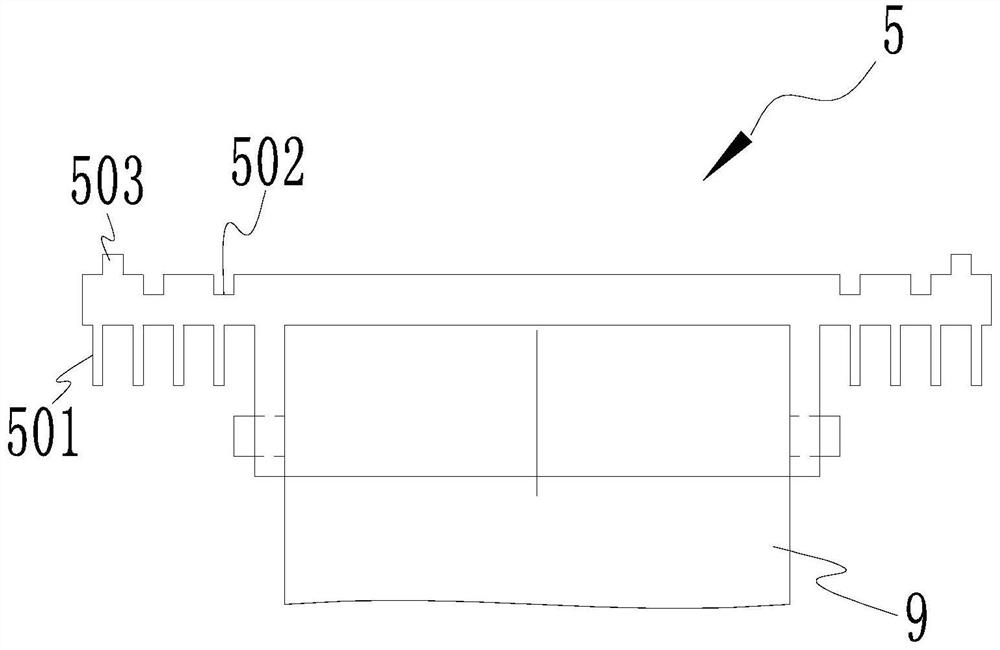

[0094] The corundum tube 9 embedded in the main body, the outer peripheral surface of the corundum tube 9 placed in the main body has an insulating layer 14, and a heating space is reserved between the insulating layer 14 and the corundum tube 9;

[0095] The upper and lower ends of the corundum tube 9 are blocked by flanges;

[0096] The flange parts are divided into an upper flange 5 installed on the upper end of the corundum tube 9, and a lower flange 16 installed on the lower end of the corun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com