Real-time on-line monitoring system and method for the safety of converter lining refractories

A technology for refractory materials and converter linings is applied in the field of real-time online monitoring systems for the safety of converter lining refractories, which can solve the problems of large influence of experience factors, lack of traceability of maintenance results, and limitation of smelting production rhythm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

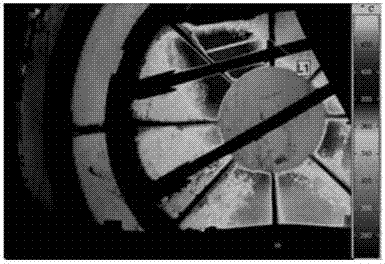

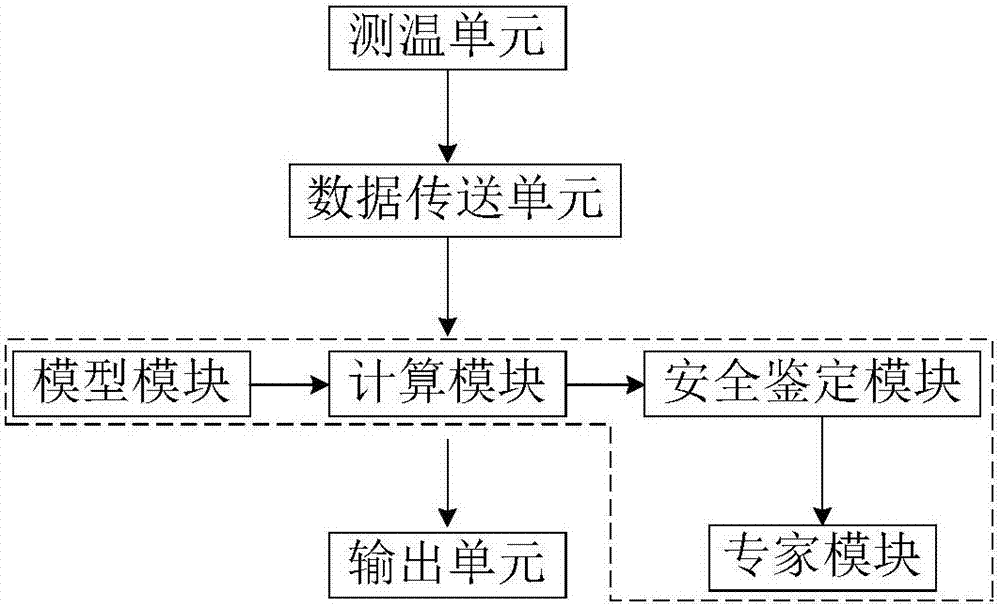

[0037] The schematic diagram of the real-time on-line monitoring method for the safety of the converter lining refractory material of the present invention is as follows figure 1 As shown, the temperature measurement unit measures the furnace shell temperature and transmits it to the data processing unit through the data transmission unit. The data transmission unit calculates the converter lining through the converter model of the model module, the furnace lining parameter module and the heat transfer principle formula and empirical correction formula of the calculation model. The thickness of the refractory material; the data processing unit contains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com