Device and method for measuring transverse wave sound velocity at high temperature

A sound velocity and transverse wave technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, measuring propagation velocity, etc., can solve the problems of reduced echo sensitivity, poor detection accuracy, etc., to achieve strong operability, easy operation, and measurement results. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

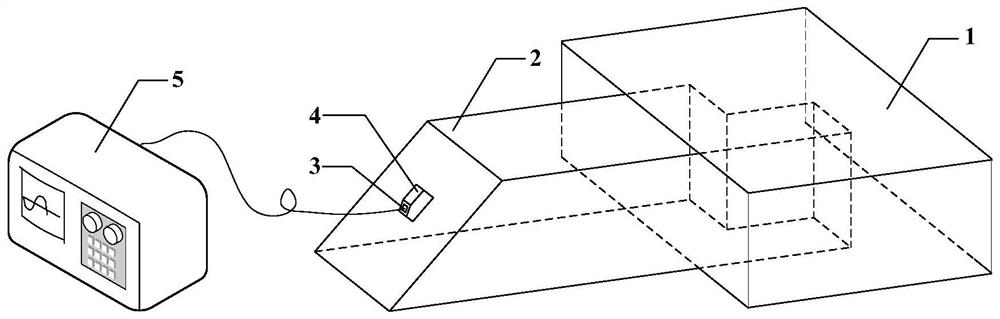

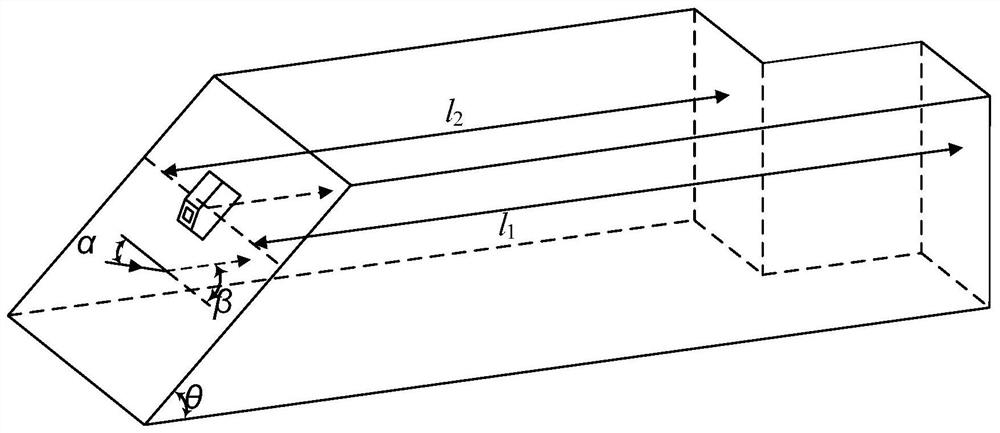

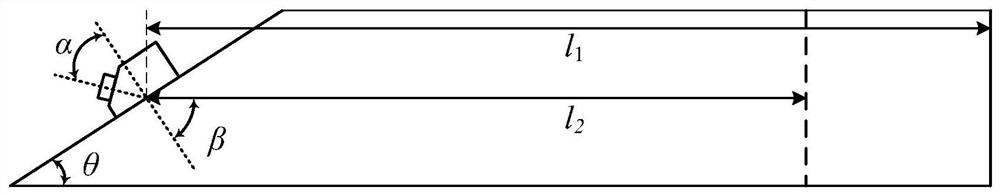

[0028] Such as figure 1 , the present invention is used to measure the device of transverse wave sound velocity under high temperature, comprises heating device 1, transverse wave sound velocity measurement test block 2, wedge block 4 and ultrasonic longitudinal wave detection system; Ultrasonic longitudinal wave detection system comprises ultrasonic longitudinal wave transducer 3 and ultrasonic detection The instrument 5, the ultrasonic longitudinal wave transducer 3 is connected to the wedge block 4 through the coupling agent layer, and the ultrasonic longitudinal wave transducer 3 is connected to the ultrasonic testing instrument 5.

[0029] One end of the shear wave sound velocity measurement test block 2 is a step structure, and the other end is a slope; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com