High-yield-strength hot-rolled section steel and production process thereof

A production process and high-yield technology, applied in the field of metallurgy, can solve the problems of easy cracks on the surface of continuous casting billets, complex cross-sectional dimensions, affecting product quality, etc., to solve the coexistence of yield strength and plasticity and toughness, and reduce fragmented graphite , the effect of improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

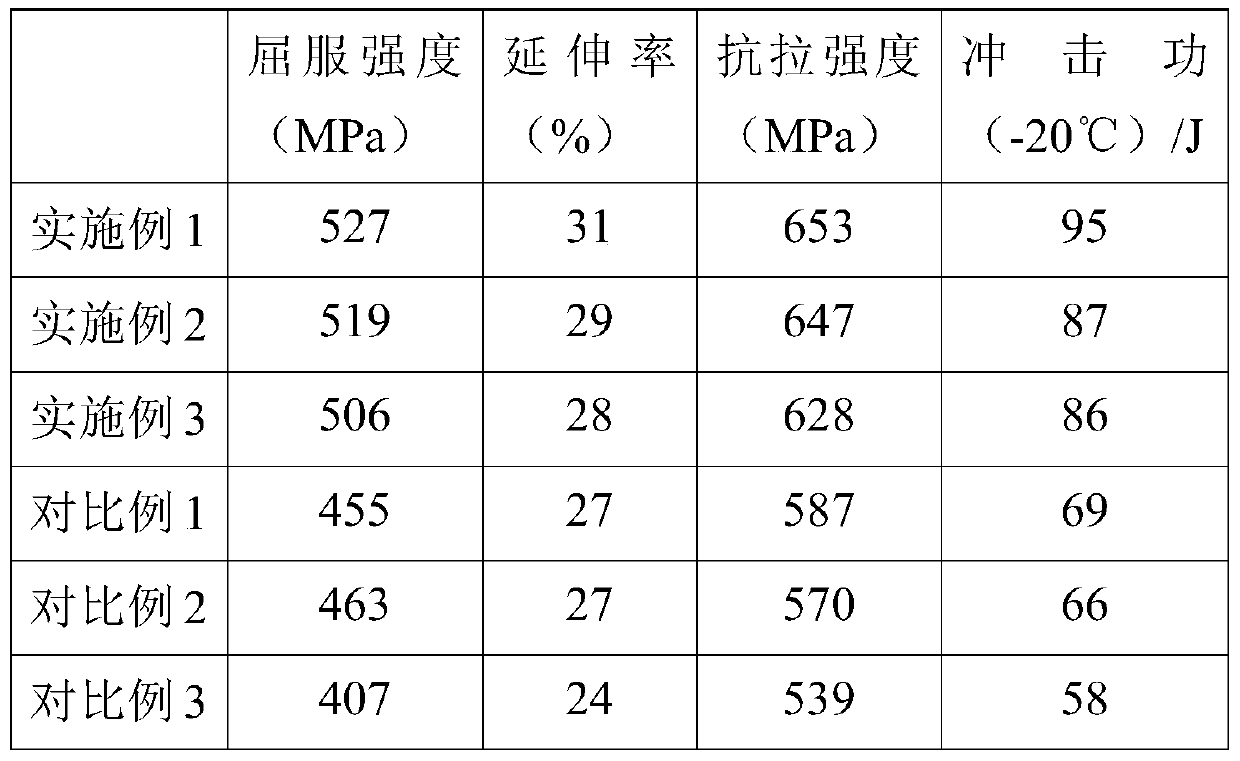

Examples

Embodiment 1

[0029] A high-yield strength hot-rolled H-shaped steel, its chemical composition by weight percentage is: C 0.15wt%, Si0.30wt%, Mn 1.0wt%, P 0.01wt%, S 0.005wt%, Cu 0.3wt%, Cr 0.4wt%, Ni 0.4wt%, Nb 0.03wt%, Ti 0.02wt%, V 0.04wt%, Ce 0.02wt%, Sb 0.03wt%, the rest is iron and trace impurities.

[0030] The production process of hot-rolled H-shaped steel comprises the following steps:

[0031] (1) Melting deoxidation: heat pig iron and / or scrap steel to 1450°C for melting, use Si and Mn for pre-deoxidation alloying in the tapping process, and use silicon-calcium for deep deoxidation alloying;

[0032] (2) Converter smelting: the basicity of the final slag is controlled at 3.0, and the tapping temperature of the converter is 1600°C;

[0033] (3) LF refining: Desulfurization is carried out according to the composition and temperature of the molten steel in the converter. Ce and Sb compounds are added in the later stage of refining to adjust the percentage of Ce and Sb elements. Th...

Embodiment 2

[0039] A high-yield strength hot-rolled H-shaped steel, its chemical composition by weight percentage is: C 0.08wt%, Si0.10wt%, Mn 0.80wt%, P 0.01wt%, S 0.005wt%, Cu 0.3wt%, Cr 0.4wt%, Ni 0.4wt%, Nb 0.03wt%, Ti 0.02wt%, V 0.04wt%, Ce 0.02wt%, Sb 0.03wt%, the rest is iron and trace impurities.

[0040] The production process of hot-rolled H-shaped steel comprises the following steps:

[0041] (1) Melting deoxidation: heat pig iron and / or scrap steel to 1420°C for melting, use Si and Mn for pre-deoxidation alloying in the tapping process, and use silicon-calcium for deep deoxidation alloying;

[0042] (2) Converter smelting: the basicity of the final slag is controlled at 3.0, and the tapping temperature of the converter is 1580°C;

[0043] (3) LF refining: Desulfurization is carried out according to the composition and temperature of molten steel in the converter. Ce and Sb compounds are added in the later stage of refining to adjust the percentage of Ce and Sb elements. The h...

Embodiment 3

[0049]A high-yield strength hot-rolled H-shaped steel, its chemical composition by weight percentage is: C 0.20wt%, Si0.40wt%, Mn 1.25wt%, P 0.01wt%, S 0.005wt%, Cu 0.40wt%, Cr 0.30wt%, Ni0.30wt%, Nb 0.04wt%, Ti 0.03wt%, V 0.02wt%, Ce 0.01wt%, Sb 0.01wt%, the rest is iron and trace impurities.

[0050] The production process of hot-rolled H-shaped steel comprises the following steps:

[0051] (1) Melting deoxidation: heat pig iron and / or scrap steel to 1480°C for melting, use Si and Mn for pre-deoxidation alloying in the tapping process, and use silicon-calcium for deep deoxidation alloying;

[0052] (2) Converter smelting: the basicity of the final slag is controlled at 3.0, and the tapping temperature of the converter is 1650°C;

[0053] (3) LF refining: Desulfurization is carried out according to the composition and temperature of the molten steel in the converter. Ce and Sb compounds are added in the later stage of refining to adjust the percentage of Ce and Sb elements. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com