Concrete containing copper tailings and preparation method thereof

A technology of copper tailings and concrete, which is applied in the field of comprehensive utilization of building materials and solid waste resources, can solve problems such as environmental pollution, waste of resources, and depletion of natural sand resources, so as to alleviate environmental pollution, reduce cost, reduce waste of resources and protect the environment. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

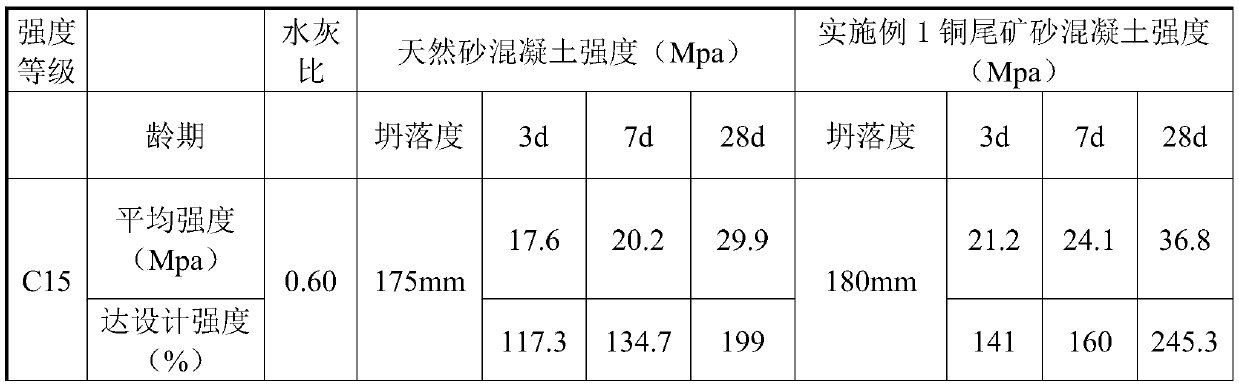

Embodiment 1

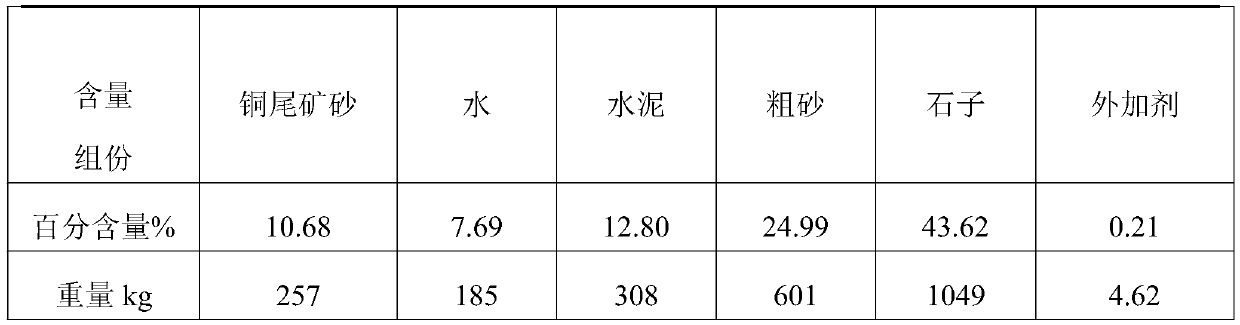

[0021] A kind of C15 concrete that contains copper tailings in the present embodiment is made up of the raw material of following weight:

[0022]

[0023] The coarse sand is river sand with a fineness modulus of 3.7-3.1.

[0024] The stones are river pebbles or waste rocks, and the stones comply with the Standards for Quality and Inspection Methods of Sand and Stones for Ordinary Concrete (JGJ52-2006).

[0025] The admixture is XLJ-2 type polycarboxylate high-performance retarding superplasticizer (produced by Shanxi Xinlongji Building Materials Co., Ltd.).

[0026] The water is a water source that meets the "Concrete Mixing Water Standard" (JGJ63-89).

[0027] The cement is general purpose cement. Such as Portland cement, ordinary Portland cement, slag Portland cement, pozzolanic Portland cement and fly ash Portland cement.

[0028] The method for preparing the above-mentioned C15 concrete containing copper tailings comprises the following steps:

[0029] The first st...

Embodiment 2

[0038] A kind of C40 concrete that contains copper tailings in the present embodiment is made up of the raw material of following weight:

[0039]

[0040] The coarse sand is river sand with a fineness modulus of 3.7-3.1.

[0041] The stones are river pebbles or waste rocks, and the stones comply with the Standards for Quality and Inspection Methods of Sand and Stones for Ordinary Concrete (JGJ52-2006).

[0042] The admixture is XLJ-2 type polycarboxylate high-performance retarding superplasticizer (produced by Shanxi Xinlongji Building Materials Co., Ltd.).

[0043] The water is a water source that meets the "Concrete Mixing Water Standard" (JGJ63-89).

[0044] The cement is general purpose cement. Such as Portland cement, ordinary Portland cement, slag Portland cement, pozzolanic Portland cement and fly ash Portland cement.

[0045] The method for preparing the above-mentioned C40 concrete containing copper tailings comprises the following steps:

[0046] The first st...

Embodiment 3

[0055] A kind of C40 concrete that contains copper tailings in the present embodiment is made up of the raw material of following weight:

[0056]

[0057] The coarse sand is river sand with a fineness modulus of 3.7-3.1. The stones are river pebbles or waste rocks, and the stones comply with the Standards for Quality and Inspection Methods of Sand and Stones for Ordinary Concrete (JGJ52-2006).

[0058] The admixture is XLJ-2 type polycarboxylate high-performance retarding superplasticizer (produced by Shanxi Xinlongji Building Materials Co., Ltd.).

[0059] The water is a water source that meets the "Concrete Mixing Water Standard" (JGJ63-89).

[0060] The cement is general purpose cement. Such as Portland cement, ordinary Portland cement, slag Portland cement, pozzolanic Portland cement and fly ash Portland cement.

[0061] The method for preparing the above-mentioned C40 concrete containing copper tailings comprises the following steps:

[0062] The first step, prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com