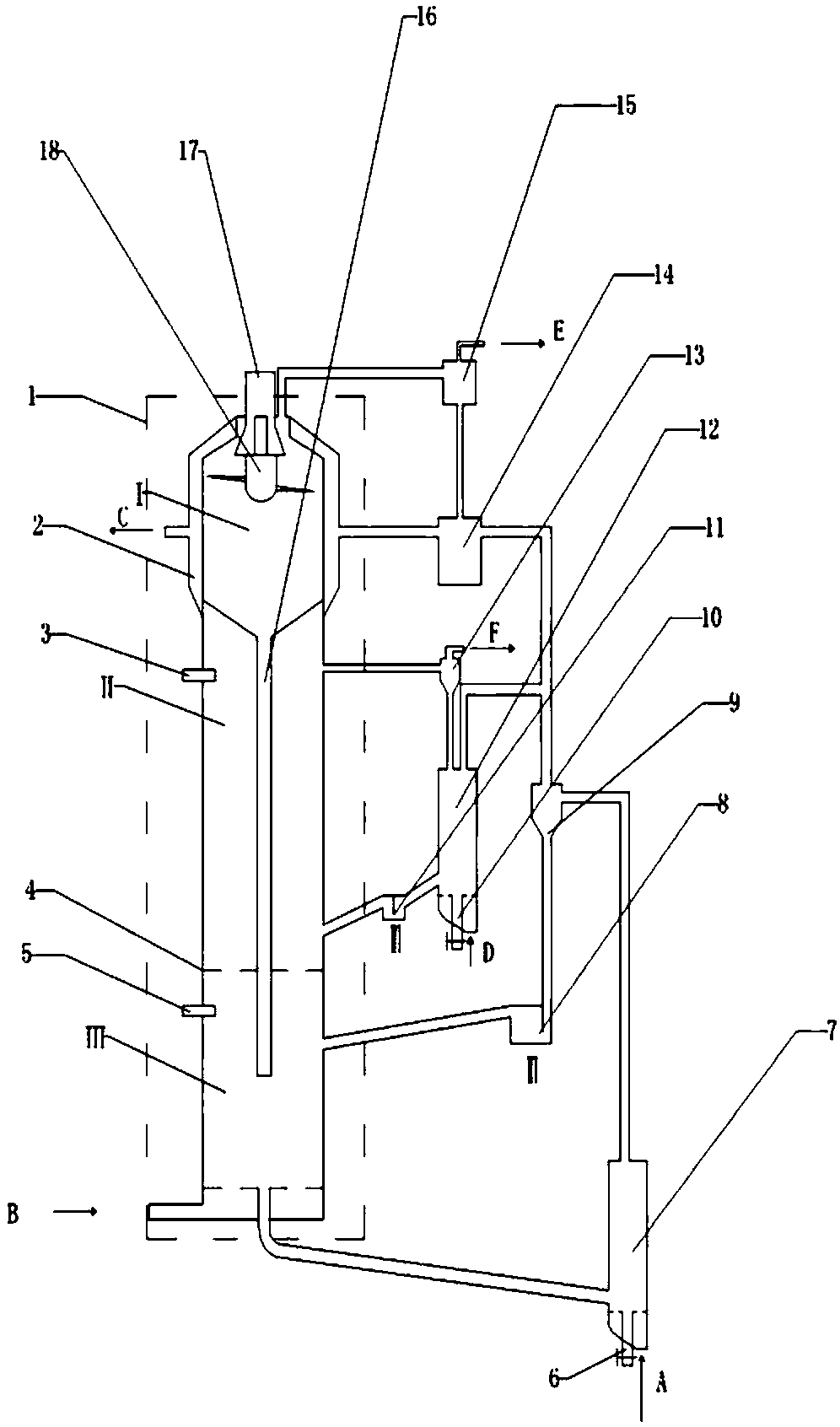

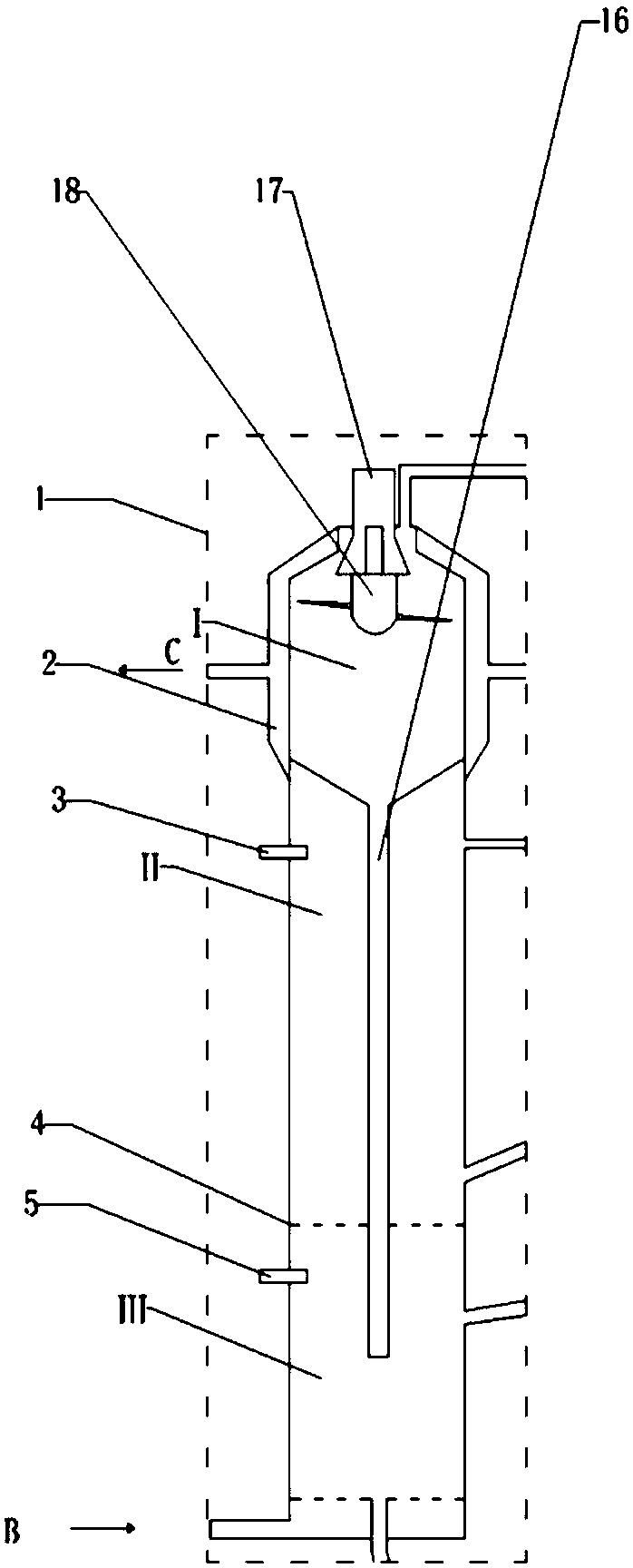

Chemical-looping-based carbon-based fuel graded combustion and dry distillation device and method

A fuel grading and chemical chain technology, applied in combustion methods, fuels burned in a molten state, fluidized bed combustion equipment, etc. The effect of increasing carbon loss, increasing conversion, and prolonging contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] Embodiment: Illinois coal is used as carbon-based fuel, iron ore as the first oxygen carrier, and pure NiO particles are used in the present invention as the second oxygen carrier, wherein the industrial analysis and elemental analysis data of coal are shown in Table 1 The composition analysis of iron ore is shown in Table 2.

[0053] In this example, the reaction temperature in the fast bed air reactor 7 is 950°C, and the temperatures of the dry distillation section I, the fluidized bed fuel reaction section II and the moving bed fuel reaction section III of the fuel reactor are respectively 600°C, 900°C and 900°C. The moving bed fuel reaction section uses iron ore to contact with coke, while NiO is used as the second oxygen carrier in the fluidized bed fuel reaction section II. There is no direct contact between coke and NiO, so impurities in carbon-based fuels, especially ash, have no effect on NiO; the residence time of coke decomposed after coal carbonization in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com