Porous carbon material preparation method, carbon-selenium composite material, and modified glassy carbon electrode

A technology of porous carbon materials and carbon materials, applied in the direction of hybrid capacitor electrodes, carbon compounds, chemical instruments and methods, etc., can solve the problems of high cost and time-consuming, etc., to expand pores, reduce production costs, and shorten production time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation of carbon materials usually requires two steps of high-temperature carbonization and activation. Specifically, the raw material is placed in an inert gas flow, and carbonized by heating at a high temperature; then it is activated in an environment of a pore-forming agent, for example, after being mixed with magnesium oxide, it is heated at a high temperature, so that a material with a high specificity can be obtained. Porous carbon materials with developed surface area and pore structure. However, from the perspective of process flow, porous carbon materials are prepared in two steps, which undoubtedly increases the required cost and time.

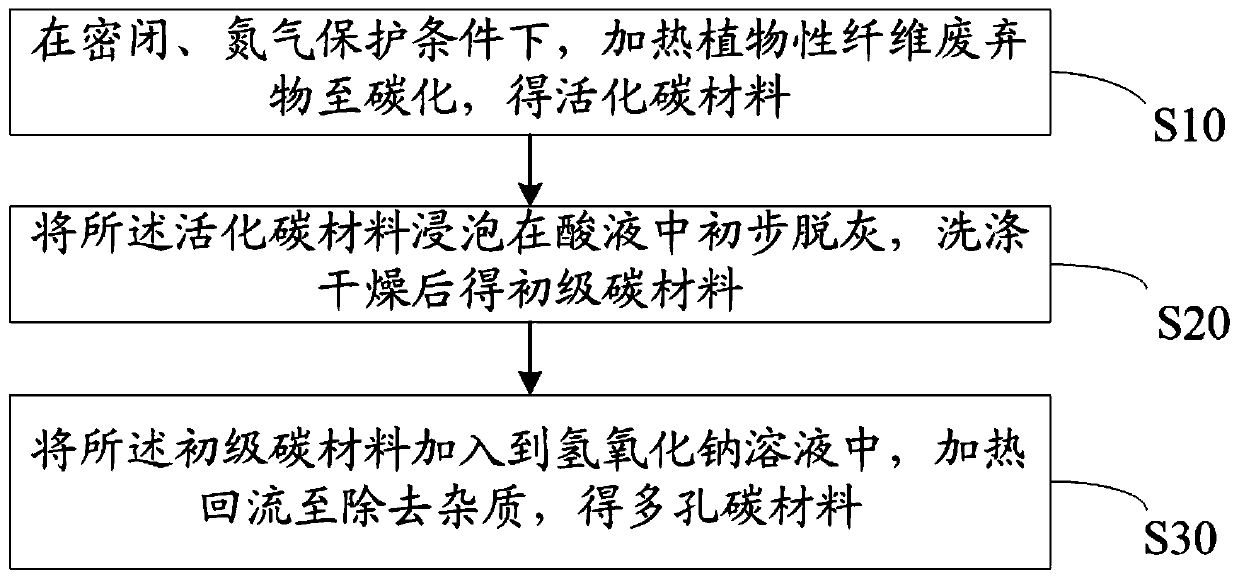

[0041] In view of this, the present invention proposes a method for preparing porous carbon materials, aiming at solving the defects of time-consuming and high cost in the current methods for manufacturing porous carbon materials. figure 1 It is an embodiment of the preparation method of the porous carbon material p...

Embodiment 1

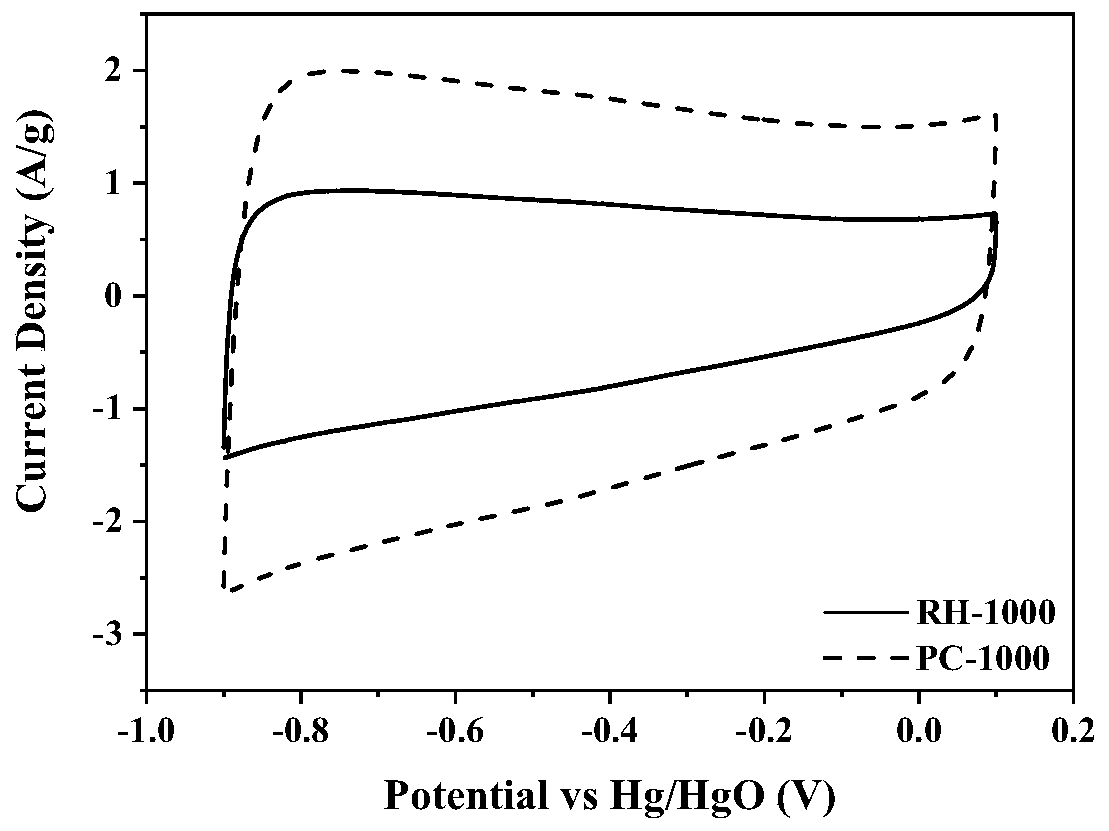

[0059] Put the chaff in a closed tube furnace, fill it with nitrogen as a protective gas, and then heat it in a closed tube at a rate of 4 °C / min to 1000 °C, and after carbonization for 2 hours, cool it down to room temperature at a rate of 4 °C / min , to obtain an activated carbon material (referred to as RH-1000). Soak the activated carbon material in 10% hydrochloric acid solution for 3 hours to deash initially, wash and dry to obtain the primary carbon material, then add the primary carbon material to 2mol / L sodium hydroxide solution, heat and reflux at 80°C for 2 hours , Porous carbon material (denoted as PC-1000) after washing and drying.

[0060] The microstructure of RH-1000 was observed by electron microscope, from figure 2 It can be seen that the surface of the activated carbon material after carbonization and activation treatment under airtight and nitrogen protection conditions has an orderly and compact raised structure, and at the same time, obvious cracks appea...

Embodiment 2

[0064] Except for the step of raising the temperature to 900° C. at a heating rate of 4° C. / min, other steps are the same as in Example 1. Wherein, in this embodiment, the obtained activated carbon material is denoted as RH-900, and the obtained porous carbon material is denoted as PC-900.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com