Plastic cake recycling device for aged oil and using method of plastic cake making and recycling device

A recovery device and aging oil technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of uncontrollable liquid shape, increase the overall footprint of plastic cakes, troublesome movement and recycling of plastic cakes, etc., so as to facilitate centralized placement and The effect of moving, improving standardization and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

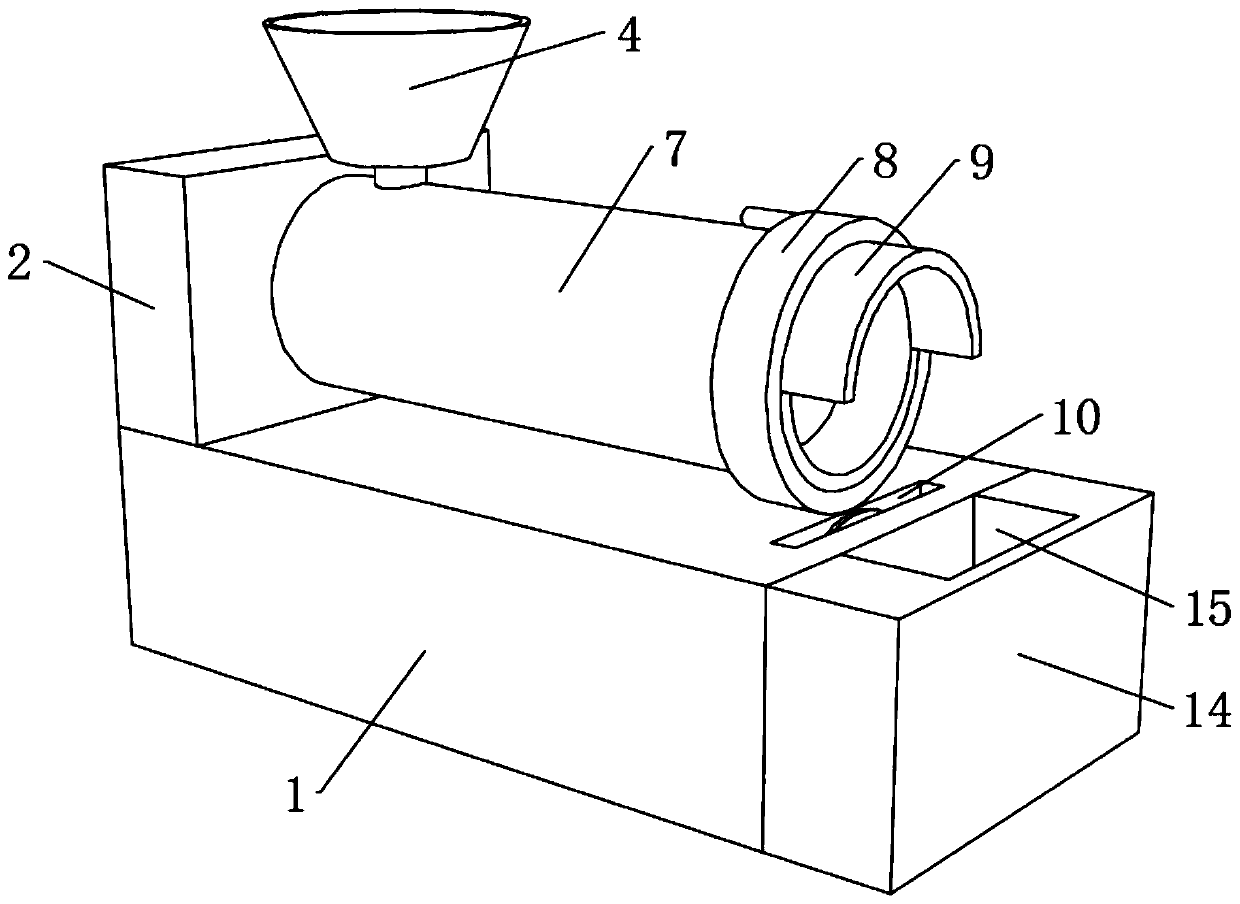

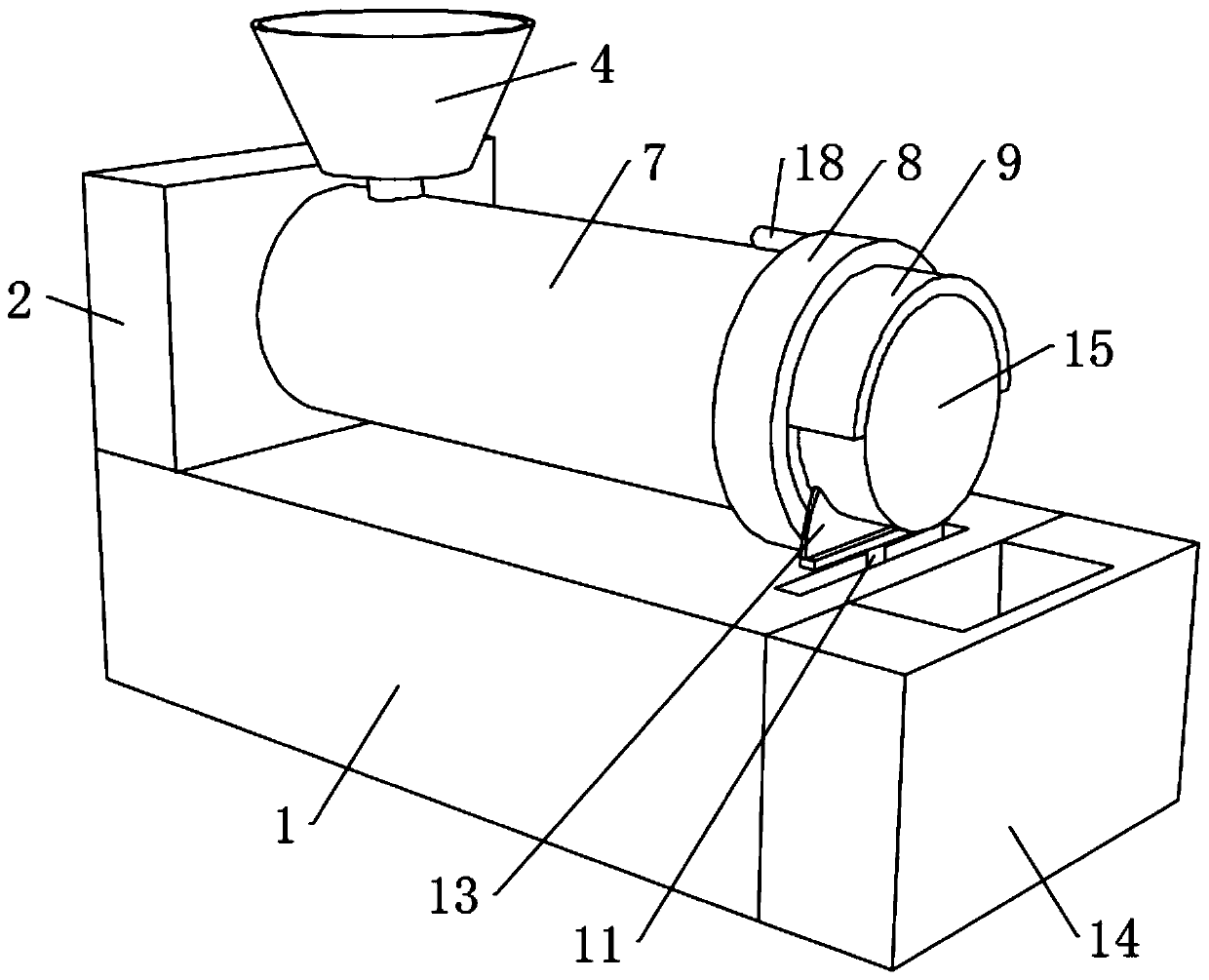

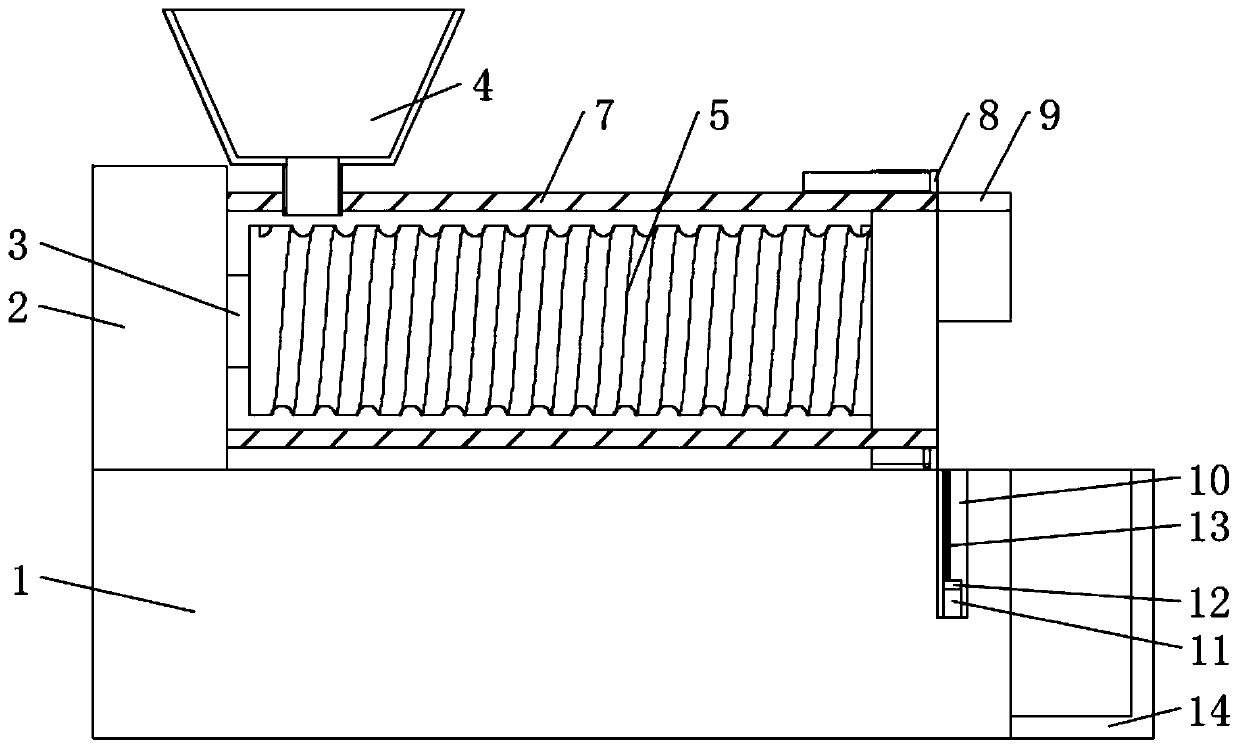

[0044] A plastic cake recycling device for aging oil, including base 1, see Figure 5 , the upper end of the base 1 is fixedly connected with the reducer 2, the motor 3 is fixedly connected inside the reducer 2, the output end of the motor 3 is fixedly connected with the electromagnetic heating tube 5, the upper end of the base 1 is fixedly connected with the protective tube 7, and the protective tube 7 is wrapped in the electromagnetic heating The outer end of the pipe 5 and the upper end of the protection pipe 7 are fixedly connected with a smoke exhaust pipe 6, and the protection pipe 7 and the smoke exhaust pipe 6 are connected to each other. Through the above-mentioned device, the plastic can be heated and softened and squeezed to reduce its volume, and then cooled into a cake shape, which is convenient The recovery of the plastic in the aging oil by the staff, the above-mentioned devices are all well-known technologies of those skilled in the art, and will not be repeated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com