A kind of preparation method of anti-sintering methanol synthesis catalyst

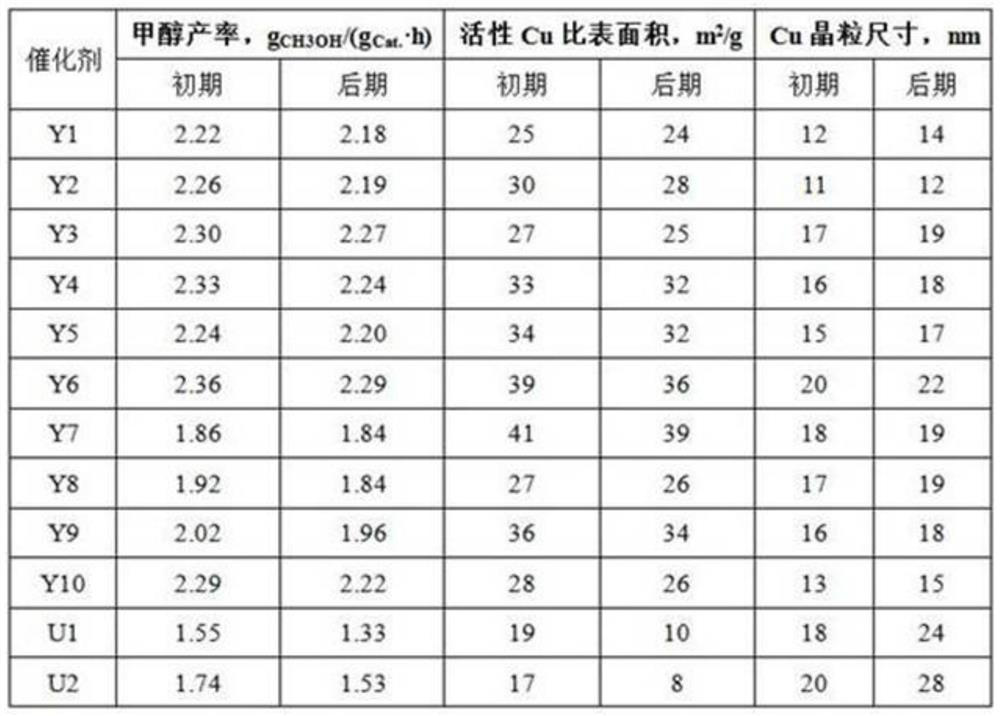

A methanol synthesis and catalyst technology, applied in the field of catalysis, can solve the problems of increasing the circulation amount, low single-pass conversion rate of raw materials, poor economy, etc., and achieve the effects of improving thermal stability, superior sintering resistance, and stabilizing active specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh copper nitrate and zinc nitrate according to the copper / zinc molar ratio of 8:1 and dissolve them in deionized water to obtain a copper-zinc solution with a total substance concentration of 1mol / L. L sodium hydroxide solution was added dropwise into the copper-zinc solution until pH=7.0 in the precipitated solution, washed and removed sodium after stirring and aging for 30 minutes, dried overnight at 90°C, and roasted at 250°C for 4h to obtain catalyst precursor a, using The specific surface area of precursor a measured by low temperature nitrogen adsorption and desorption technology is 80m 2 / g, weigh 10g of precursor a as the raw material for subsequent steps.

[0024] Take silica sol and aluminum nitrate to prepare 100mL silicon-aluminum mixed solution, so that the total mass of silicon and aluminum elements in the solution is 0.08g, and the molar ratio of silicon / aluminum element is 1:4; immerse 10g of catalyst precursor a in the silicon-aluminum mixed solut...

Embodiment 2

[0027] Weigh copper nitrate and zinc nitrate according to the copper / zinc element molar ratio of 7:1 and dissolve them in deionized water to obtain a copper-zinc solution with a total substance concentration of 1mol / L. L sodium carbonate solution was added dropwise into the copper-zinc solution until pH=7.2 in the precipitated solution, stirred and aged for 30 minutes, washed to remove sodium, dried overnight at 100°C, and calcined at 300°C for 3 hours to obtain catalyst precursor a. The specific surface area of precursor a measured by nitrogen adsorption and desorption technology is 60m 2 / g, weigh 10g of precursor a as the raw material for subsequent steps.

[0028] Take silica sol and aluminum nitrate to prepare 100mL silicon-aluminum mixed solution, so that the total mass of silicon and aluminum in the solution is 0.3g, and the molar ratio of silicon / aluminum is 1:3; immerse 10g of catalyst precursor a in the silicon-aluminum mixed solution 1.0mol / L sodium bicarbonate s...

Embodiment 3

[0031] Weigh copper nitrate and zinc nitrate according to the copper / zinc molar ratio of 5:1 and dissolve them in deionized water to obtain a copper-zinc solution with a total substance concentration of 1mol / L. L sodium carbonate solution was added dropwise to the copper-zinc solution until pH=7.2 in the precipitated solution, stirred and aged for 30 minutes, washed to remove sodium, dried overnight at 120°C, and calcined at 350°C for 1 hour to obtain catalyst precursor a. The specific surface area of precursor a measured by nitrogen adsorption and desorption technology is 65m 2 / g, weigh 10g of precursor a as the raw material for subsequent steps.

[0032] Take silica sol and aluminum nitrate to prepare 100mL silicon-aluminum mixed solution, so that the total mass of silicon and aluminum in the solution is 0.61g, and the molar ratio of silicon / aluminum is 1:2; 10g of catalyst precursor a is immersed in the silicon-aluminum mixed solution 1.2mol / L sodium carbonate solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com