a high co 2 Preparation method of catalyst for methanol production from synthesis gas

A technology of CO2 and synthesis gas, which is applied in the field of catalysis, can solve the problems of difficult control of preparation conditions, many factors for performance improvement investigation and adjustment, and difficult molding of catalysts, etc., to achieve stable activity specific surface area, superior anti-sintering ability, and improved The effect of hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

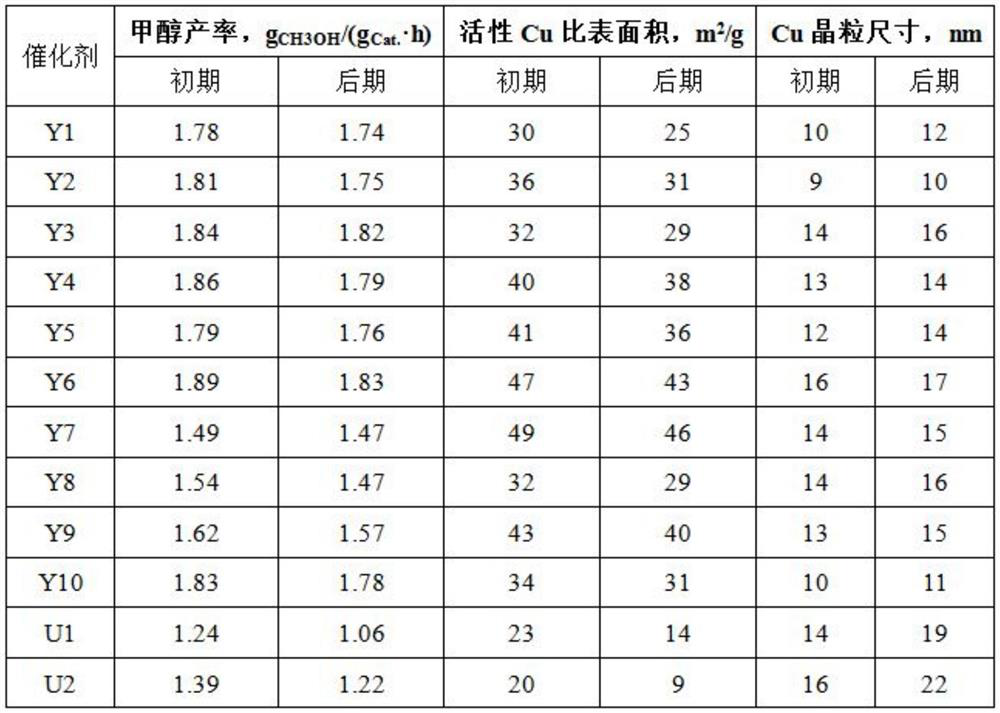

Examples

Embodiment 1

[0019] Be that 8:1:0.45 take copper nitrate, zinc nitrate and aluminum nitrate according to copper / zinc / aluminum element mol ratio and be dissolved in deionized water, obtain the copper-zinc-aluminum solution that the amount concentration of total substance is 1mol / L, at 60 ℃ under vigorous stirring, add 0.5mol / L sodium hydroxide solution dropwise to the copper-zinc-aluminum solution until pH=7.0 in the precipitation solution, stir and age for 30 minutes, then wash to remove sodium, dry overnight at 90℃, and roast at 250℃ After 4 hours, powder 1 was obtained, and the specific surface area of powder 1 was measured to be 120m by low-temperature nitrogen adsorption and desorption technology. 2 / g, weigh 10g of powder 1 as the raw material for subsequent steps.

[0020] Take silica sol and aluminum nitrate to prepare 100mL silicon-aluminum mixed solution, so that the total mass of silicon and aluminum in the solution is 0.12g, and the molar ratio of silicon / aluminum is 1:4; imme...

Embodiment 2

[0023] Take copper nitrate, zinc nitrate and aluminum nitrate according to copper / zinc / aluminum element mol ratio is 7:1:0.8 and be dissolved in deionized water, obtain the copper-zinc-aluminum solution that the amount concentration of total substance is 1mol / L, at 65 Under vigorous stirring at ℃, add 1.0mol / L sodium carbonate solution dropwise to the copper-zinc-aluminum solution until pH=7.2 in the precipitated solution, stir and age for 30 minutes, then wash to remove sodium, dry overnight at 100℃, and roast at 300℃ for 3h , to obtain powder 1, the specific surface area of powder 1 measured by low-temperature nitrogen adsorption and desorption technology is 90m 2 / g, weigh 10g of precursor a as the raw material for subsequent steps.

[0024] Take silica sol and aluminum nitrate to prepare 100mL silicon-aluminum mixed solution, so that the total mass of silicon and aluminum in the solution is 0.45, and the molar ratio of silicon / aluminum is 1:3; 10g of powder 1 is immersed...

Embodiment 3

[0027] Take copper nitrate, zinc nitrate and aluminum nitrate according to copper / zinc / aluminum element mol ratio is 5:1:0.9 and be dissolved in deionized water, obtain the copper-zinc-aluminum solution that the amount concentration of total substance is 1mol / L, at 65 Under vigorous stirring at ℃, add 1.2mol / L sodium carbonate solution dropwise to the copper-zinc-aluminum solution until pH = 7.2 in the precipitated solution. After stirring and aging for 30 minutes, wash to remove sodium, dry overnight at 120℃, and roast at 350℃ for 1 hour , to obtain powder 1, the specific surface area of powder 1 measured by low-temperature nitrogen adsorption and desorption technology is 91m 2 / g, weigh 10g of precursor a as the raw material for subsequent steps.

[0028] Take silica sol and aluminum nitrate to prepare 100mL silicon-aluminum mixed solution, so that the total mass of silicon and aluminum in the solution is 0.854g, and the molar ratio of silicon / aluminum is 1:2; immerse 10g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com