A cobalt-nickel bimetallic organic framework carbon dioxide adsorption material and its preparation method and application

An organic framework and carbon dioxide technology, applied in the direction of alkali metal oxides/hydroxides, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of easily blocked pore adsorption capacity, low introduction amount, difficult introduction of amino groups, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

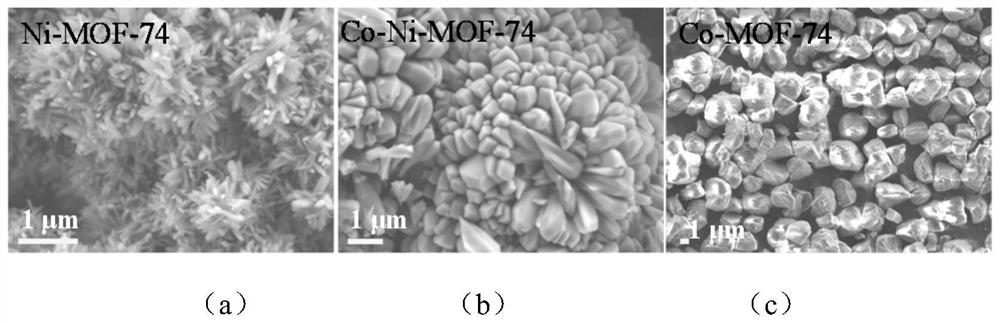

[0036] Preparation of cobalt-nickel bimetallic organic frameworks by rapid microwave heating:

[0037] Containing 1.5g of nickel nitrate and cobalt acetate (the mass ratio of nickel nitrate and cobalt acetate is 1:1) metal salt precursor and 50mL of ultrapure water to form a homogeneous solution A;

[0038] 0.5g of 2,5-dihydroxyterephthalic acid was dissolved in a mixed solution of 50mL absolute ethanol and 50mL DMF to obtain solution B.

[0039] Finally, the A and B solutions were ultrasonically oscillated and mixed evenly. The above mixed solution was heated to 140°C for 1 hour in a microwave-ultrasonic-ultrasonic trinity synthesis reactor, and reacted for 1 hour, filtered, washed, dried, and then activated for 4-6 hours at 200-250°C under vacuum conditions to obtain a series of Co-Ni-MOF-74 with abundant micropores and unsaturated coordination bonds.

Embodiment 2

[0058] A preparation method of a cobalt-nickel bimetallic organic framework carbon dioxide adsorption material is as follows: nickel nitrate and cobalt acetate are dissolved in water to form solution A; wherein the mass ratio of nickel nitrate and cobalt acetate in solution A is 1:1.

[0059] Dissolving 2,5-dihydroxyterephthalic acid in a solution containing ethanol and N,N-dimethylformamide to form solution B;

[0060] Mix solution A and solution B evenly to obtain a mixed solution, then heat the mixed solution to 110°C for 60 minutes in a microwave ultraviolet ultrasonic trinity synthesis reactor, filter, wash and dry, and then activate at 200°C under vacuum Treat for 6 hours to obtain a bimetallic organic framework carbon dioxide adsorption material;

[0061] Among them, the volume ratio of water, ethanol and N,N-dimethylformamide is 1:0.5:5; the mass ratio of the total mass of nickel nitrate and cobalt acetate to 2,5-dihydroxyterephthalic acid is 3:1 ; The total mass frac...

Embodiment 3

[0063] A preparation method of a cobalt-nickel bimetallic organic framework carbon dioxide adsorption material is as follows: nickel nitrate and cobalt acetate are dissolved in water to form solution A; wherein, the mass ratio of nickel nitrate and cobalt acetate in solution A is 1:6.

[0064] Dissolving 2,5-dihydroxyterephthalic acid in a solution containing ethanol and N,N-dimethylformamide to form solution B;

[0065] Mix solution A and solution B evenly to obtain a mixed solution, then heat the mixed solution to 120°C for 40 minutes in a microwave ultraviolet ultrasonic trinity synthesis reactor, filter, wash and dry, and then activate at 250°C under vacuum Treat for 4 hours to obtain a bimetallic organic framework carbon dioxide adsorption material;

[0066] Among them, the volume ratio of water, ethanol and N,N-dimethylformamide is 1:3:3; the mass ratio of the total mass of nickel nitrate and cobalt acetate to 2,5-dihydroxyterephthalic acid is 4:1 ; The total mass fract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com