High-efficient water-purifying activated carbon and preparation method thereof

A technology for activated carbon and water purification, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve the problems of unsatisfactory water purification effect and incomplete purification of activated carbon, and achieve good water purification effect and good purification. Water effect, the effect of well-developed micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

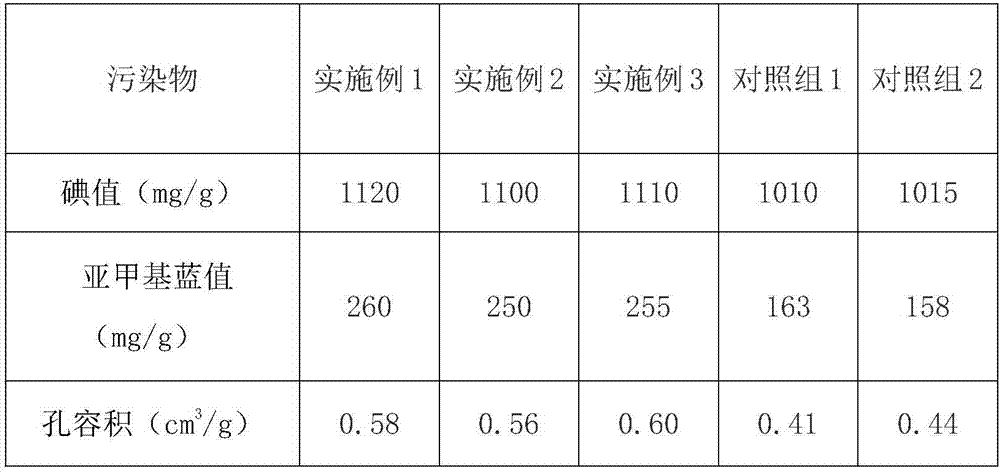

Examples

Embodiment 1

[0024] A high-efficiency water-purifying activated carbon, made of the following raw materials in parts by weight: 70 parts of activated carbon, 30 parts of modified diatomite, 20 parts of zeolite, 20 parts of kaolin, 8 parts of alum powder, 5 parts of montmorillonite, sea foam 10 parts of stone powder, 4.5 parts of calcium carbonate, 7 parts of binder and 40 parts of deionized water.

[0025] Wherein, the modified bentonite is made of the following raw materials in parts by weight: 85 parts of diatomite, 5 parts of sodium alginate, 5 parts of clove oil, 3 parts of ascorbic acid, 4 parts of Gynostemma powder, 25 parts of 10-15% hydrochloric acid solution The preparation method: put the diatomite in a calciner and calcinate at 580°C for 4 hours, take it out, soak it in 10-15% hydrochloric acid solution for 3 hours, filter it out, wash and dry it, add it to water, add sodium alginate, Clove oil, ascorbic acid, and Gynostemma pentaphyllum powder are used to obtain a slurry, spray...

Embodiment 2

[0037] A high-efficiency activated carbon for water purification is made of the following raw materials in parts by weight: 60 parts of activated carbon, 20 parts of modified diatomite, 15 parts of zeolite, 10 parts of kaolin, 5 parts of alum powder, 3 parts of montmorillonite, sea foam 5 parts of stone powder, 3 parts of calcium carbonate, 4 parts of binder and 30 parts of deionized water.

[0038] Wherein, the modified bentonite is made of the following raw materials in parts by weight: 80 parts of diatomite, 3 parts of sodium alginate, 2 parts of clove oil, 1 part of ascorbic acid, 2 parts of Gynostemma powder, 20-15% hydrochloric acid solution 30 parts; its preparation method: put diatomaceous earth in a calciner and calcinate at 550°C for 3 hours, take it out, soak it in 10-15% hydrochloric acid solution for 2 hours, filter it out, wash and dry it, add water, add alginic acid Sodium, clove oil, ascorbic acid, gynostemma powder, to obtain slurry, spray drying, grinding and...

Embodiment 3

[0050]A high-efficiency activated carbon for water purification is made of the following raw materials in parts by weight: 80 parts of activated carbon, 40 parts of modified diatomite, 25 parts of zeolite, 30 parts of kaolin, 10 parts of alum powder, 8 parts of montmorillonite, sea foam 15 parts of stone powder, 6 parts of calcium carbonate, 10 parts of binder and 50 parts of deionized water.

[0051] Among them, 70 parts of activated carbon, 30 parts of modified diatomite, 20 parts of zeolite, 20 parts of kaolin, 8 parts of alum powder, 5 parts of montmorillonite, 10 parts of sepiolite powder, 4.5 parts of calcium carbonate, binder 7 parts and 40 parts of deionized water.

[0052] Wherein, the modified bentonite is made of the following raw materials in parts by weight: 90 parts of diatomite, 8 parts of sodium alginate, 8 parts of clove oil, 5 parts of ascorbic acid, 6 parts of gynostemma powder, 30 parts of 10-15% hydrochloric acid solution The preparation method: put diato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com