Method for purifying and absorbing spraying granulation flue gas by utilizing resin complex

A technology of resin composites and spray granulation, which is applied in the direction of chemical instruments and methods, separation methods, dispersion particle separation, etc., to achieve the effects of improving adsorption effect, improving compatibility, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for purifying and absorbing the spray granulation flue gas by using the resin compound comprises the following steps: the spray granulation flue gas first passes through the spray washing tower for spray washing, and the temperature is lowered to below 33°C, and then enters the resin compound Purify and absorb in the reaction chamber, and then discharge.

[0032] The resin complex is prepared from a resin adsorption carrier and a composite bacterial liquid;

[0033] The resin composite is prepared according to the following steps: add the composite bacterial solution to a resin adsorption carrier with 1.5 times the mass, stir at 100 rpm for 30 minutes, then let it stand for 6 hours, collect the solid matter by filtration, and finally dry it at low temperature.

[0034] The preparation method of the resin adsorption carrier comprises the following steps:

[0035] Add 10wt% methanol and 2wt% methylene blue to 1M sodium acetate aqueous solution, stir evenly, he...

Embodiment 2

[0042] The method for purifying and absorbing the spray granulation flue gas by using the resin compound comprises the following steps: the spray granulation flue gas first passes through the spray washing tower for spray washing, and the temperature is lowered to below 33°C, and then enters the resin compound Purify and absorb in the reaction chamber, and then discharge.

[0043] The resin complex is prepared from a resin adsorption carrier and a composite bacterial liquid;

[0044] The resin composite is prepared according to the following steps: add the composite bacterial liquid to a resin adsorption carrier with twice the mass, stir at 100 rpm for 30 minutes, then let it stand for 6 hours, collect the solid matter by filtration, and finally dry it at low temperature.

[0045] The preparation method of the resin adsorption carrier comprises the following steps:

[0046] Add 10wt% methanol and 2wt% methylene blue to 1M sodium acetate aqueous solution, stir evenly, heat to ...

Embodiment 3

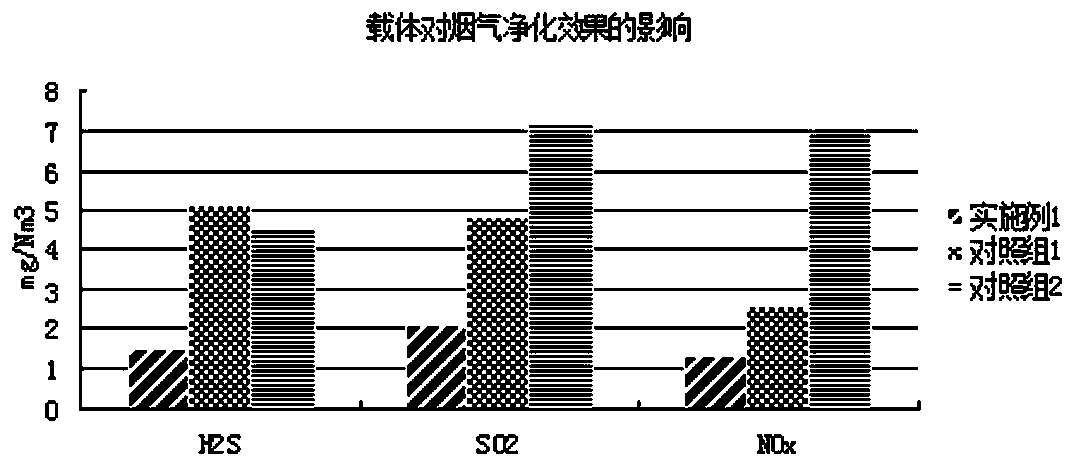

[0053] Performance test of resin adsorption carrier of the present invention:

[0054] Taking Example 1 as an example, the control group did not add nano-silica gel powder and coupling agent vinyltriethoxysilane, and the specific surface area, average particle size, and cell adhesion (dry weight) of the carrier were detected, as shown in Table 1. :

[0055] Table 1

[0056] group Specific surface area m 2 / g

[0057] It can be seen from Table 1 that after modification with nano-silica gel powder, the specific surface area of the resin carrier reaches 739m 2 / g, compared with the unmodified control group, it has increased by 31.7%, and the amount of bacterial strain attachment has also been significantly improved, compared with the unmodified control group, it has increased by 67.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com