Visual plugging evaluation device and use method thereof

A technology for evaluating devices and plugging slurry, which is used in measurement devices, instruments, scientific instruments, etc., can solve the problem that the particle size of the plugging material is difficult to match with the pore size of the formation, and it is impossible to observe the plugging of the leakage channel by the plugging material. Condition, plugging formula and poor matching of pore channels, etc., to achieve the effect of convenient and quick disassembly, easy storage and carrying, uniform metallographic structure and pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] as attached figure 1 As shown, a visual plugging evaluation device includes a simulated wellbore mechanism 1, a simulated formation mechanism 2 and a measurement mechanism 3 connected in sequence;

[0040] Among them, the simulated wellbore mechanism 1 includes a compressed gas source 11 connected in sequence, a compressed gas pipeline 12 and a vertically arranged slurry holding pipe 13, and the compressed gas pipeline 12 is connected to the top of the slurry containing pipe 13; there is a pressure regulating valve at the outlet of the compressed gas source 1 14 and pressure gauge 15;

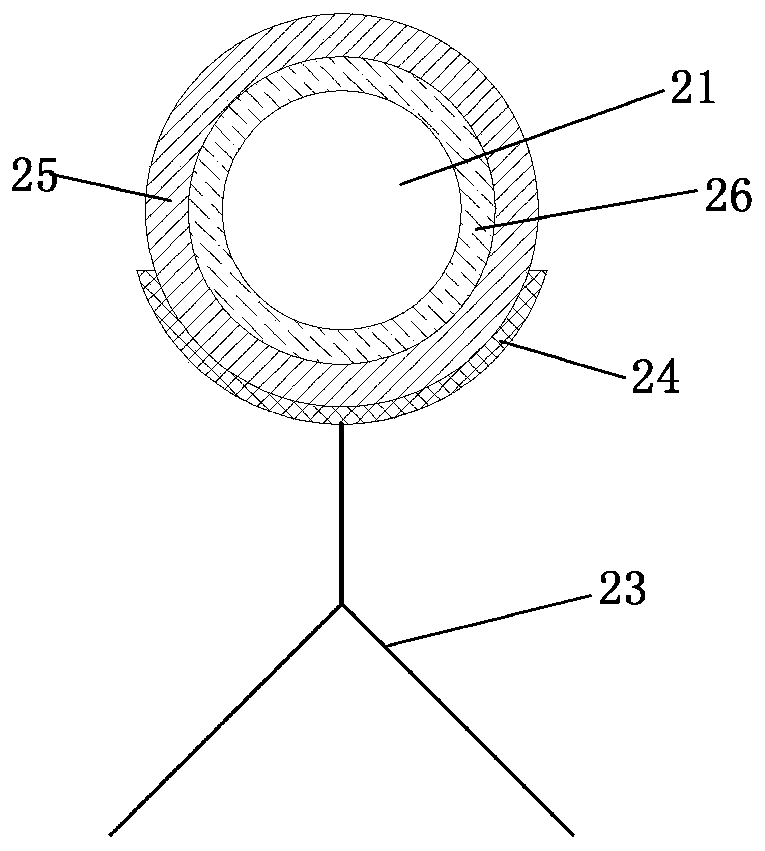

[0041] The simulated formation mechanism 2 includes visual tubes 21 and outlet valves 22 arranged horizontally and connected in sequence; the two ends of the visible tubes 21 have filter screens, and the outer wall is covered with a visible reinforcement layer 25 and a transparent material insulation layer 26;

[0042] It also includes a support frame 23 on which the visible tube 21 is ...

Embodiment 2

[0053] as attached figure 1 As shown, a visual plugging evaluation device includes a simulated wellbore mechanism 1, a simulated formation mechanism 2 and a measurement mechanism 3 connected in sequence;

[0054]Among them, the simulated wellbore mechanism 1 includes a compressed gas source 11 connected in sequence, a compressed gas pipeline 12 and a vertically arranged slurry holding pipe 13, and the compressed gas pipeline 12 is connected to the top of the slurry containing pipe 13; there is a pressure regulating valve at the outlet of the compressed gas source 1 11 and pressure gauge 12;

[0055] The simulated formation mechanism 2 includes visual tubes 21 and outlet valves 22 arranged horizontally and connected in sequence; the two ends of the visible tubes 21 have filter screens, and the outer wall is covered with a visible reinforcement layer 25 and a transparent material insulation layer 26;

[0056] Also include support frame 23 and support plate 24, support plate 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com