Drilling fluid for improving sliding efficiency of highly-deviated large cluster wells and construction method

A technology for highly deviated wells and construction methods, applied in wellbore/well components, chemical instruments and methods, earthwork drilling and production, etc., can solve problems such as complex situations and accidents, serious underpressure, poor results, etc. The effect of high screening rate, fast machine speed and low frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

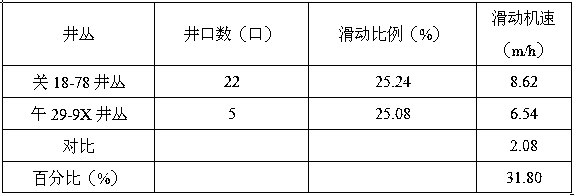

Image

Examples

Embodiment 1

[0037] A drilling fluid for improving the sliding efficiency of large cluster wells and highly deviated wells, consisting of the following substances in mass percentage:

[0038] Inhibitors, 5-10%;

[0039] Soluble weighting agent, 12-17%;

[0040] Viscosity increasing fluid loss reducing agent, 1.3~1.85%;

[0041] Flow regulator, 0.1~0.5%;

[0042] The balance is water.

[0043] Principle of the present invention is as follows:

[0044] Drilling fluid does not add non-dissolved solid phases, such as bentonite, limestone, barite, etc., and uses soluble soluble weighting agents to increase the density. The inhibitor is used to inhibit the hydration of clay minerals. The cuttings particles are complete and the screening rate is high. ;Because there is no solid phase in the drilling fluid, the frictional resistance is lower than that of other drilling fluid systems, which is conducive to sliding drilling, and the sliding drilling tool surface is in place, the sliding drilling...

Embodiment 2

[0046] A drilling fluid for improving the sliding efficiency of large cluster wells and highly deviated wells, consisting of the following substances in mass percentage:

[0047] Inhibitor, 5%;

[0048] Soluble weighting agent, 12%;

[0049] Viscosity increase fluid loss reducer, 1.3%;

[0050] Flow regulator, 0.1%;

[0051] The rest is clear water.

[0052] In this embodiment, inorganic salts are selected as inhibitors, which can inhibit the hydration and dispersion of mud shale and prevent the drill bit bag and well wall from collapsing.

[0053] The soluble weighting agent is a compound salt composed of sodium formate, sodium sulfate and potassium sulfate, wherein the mass percentage of sodium formate is 35%, the mass percentage of sodium sulfate is 50%, and the mass percentage of potassium sulfate is 15%.

[0054] The viscosity-increasing and fluid-loss reducing agent is BLA-HV, a terpolymer of propylene monomers, purchased from Dongying Baolong Petroleum New Technolog...

Embodiment 3

[0057] A drilling fluid for improving the sliding efficiency of large cluster wells and highly deviated wells, consisting of the following substances in mass percentage:

[0058] Inhibitors, 7%;

[0059] Soluble weighting agent, 15%;

[0060] Viscosity increase fluid loss reducer, 1.5%;

[0061] Flow regulator, 0.2%;

[0062] The rest is clear water.

[0063] In this embodiment, the inorganic salt KCl is selected as the inhibitor, which is beneficial for recovery and reuse.

[0064] The soluble weighting agent is a compound salt composed of sodium formate, sodium sulfate and potassium sulfate, wherein the mass percentage of sodium formate is 40%, the mass percentage of sodium sulfate is 50%, and the mass percentage of potassium sulfate is 10%.

[0065] The viscosity-increasing and fluid-loss reducing agent is BLA-HV, a terpolymer of propylene monomers, purchased from Dongying Baolong Petroleum New Technology Co., Ltd. It can improve viscosity shear of drilling fluid, redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com