Water-based flame-retardant inorganic coating for surface of aluminum product as well as preparation method and application of water-based flame-retardant inorganic coating

A technology for inorganic coatings and aluminum products, applied in anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of high VOC, low hardness, high temperature resistance and combustion resistance, etc., and achieve good adhesion and resistance to cold and heat alternation The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] An aspect of the embodiments of the present invention provides a method for preparing the aforementioned water-based flame-retardant inorganic coating, which includes:

[0044] Mix silica sol and aluminum sol evenly, then add defoamer and mix evenly to form component A;

[0045] Mix dispersant, methyl siloxane and ethanol evenly, then add anti-settling agent, thickener, anti-settling agent, inorganic flame retardant pigment, inorganic flame retardant filler and ultrasonically disperse and mix evenly to form component B;

[0046] And, the A component and the B component are uniformly mixed, and ultrasonically dispersed and mixed uniformly to form the water-based flame-retardant inorganic coating.

[0047] Further, the preparation method specifically includes:

[0048] Mix silica sol and aluminum sol evenly, then add defoamer and mix, and stir for 30-50min at a speed of 300-800r / min to form component A;

[0049] Mix dispersant, methyl siloxane, and ethanol evenly, then ...

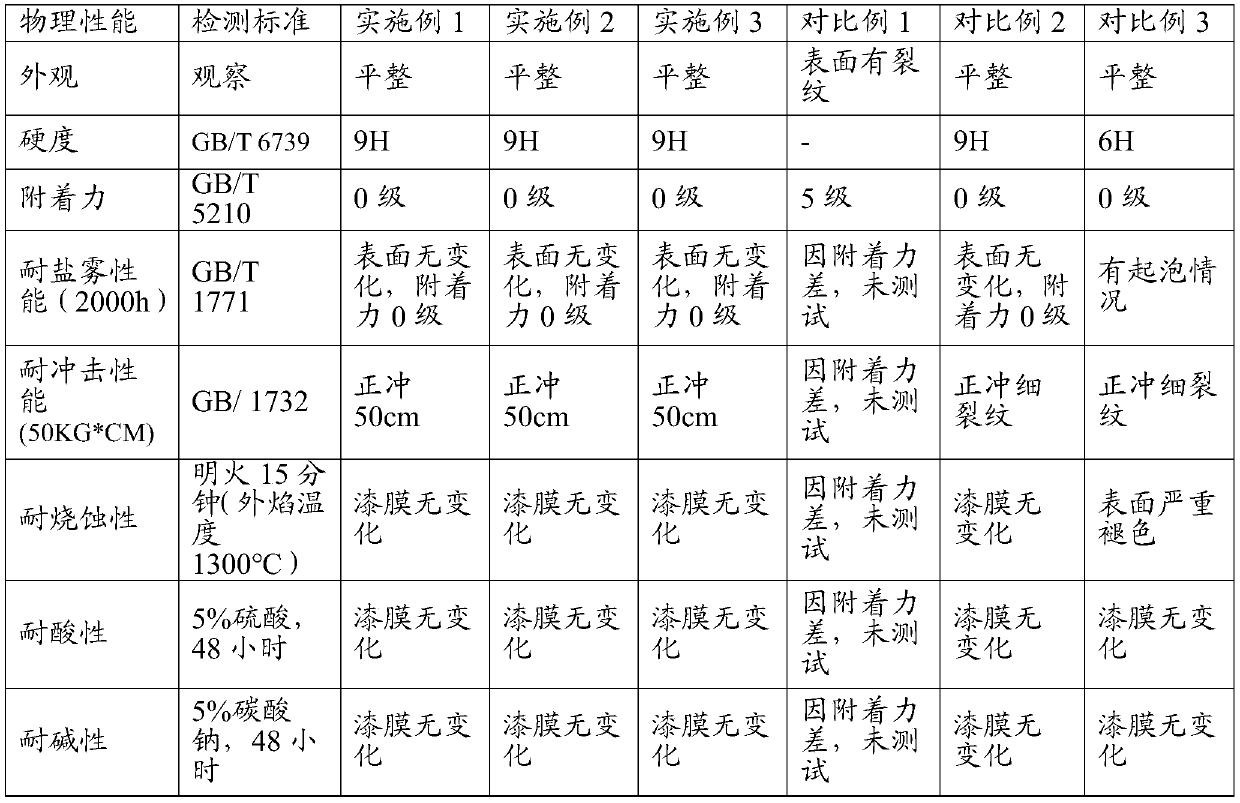

Embodiment 1

[0061] Add 10g of aluminum sol (purchased from Zibo Jiarun Chemical) to 30g of silica sol (purchased from Shandong Baite New Materials, pH=8.0) under stirring, stir at 500r / min for 30 minutes, and then add 0.5g of defoaming Agent (purchased from Gas Chemical), after stirring at 500r / min for 30 minutes, component A is obtained. Take another 30g of methylsiloxane (purchased from Dow Corning Company), add 1g of dispersant (purchased from BYK Company), add 6g of ethanol, stir evenly, and add 6g of glass powder (purchased from Xianyang Yinghe, 2000 mesh) while stirring , 5g barium sulfate (purchased from Shahali Ben), 1g anti-settling agent (purchased from Degussa Company, R972), 0.5g thickener (purchased from Huzhou Walter, brand 140W), 10g cobalt green pigment (purchased From Wuhu Kuke), ultrasonically dispersed for 30 minutes to obtain component B. After mixing components A and B evenly, disperse in airtight ultrasonic for 30 minutes, cool down to room temperature after the mix...

Embodiment 2

[0063] 40g of silica sol (purchased from Zhejiang Yuda Chemical, pH=8.0) was added with 10g of aluminum sol (purchased from Zibo Jiarun Chemical) under stirring, stirred at 300r / min for 30 minutes, and then 1g of defoamer ( Purchased from BYK Chemical), after stirring at 300r / min for 30 minutes, component A is obtained. Take another 20g of methyl siloxane (purchased from Xinyue Company), add 2g of dispersant (purchased from TEGO Company), add 5g of ethanol, stir evenly, add 6g of talcum powder (purchased from Chuangyu Chemical, 3000 mesh) while stirring , 4g barium sulfate (purchased from Shahali Ben), 1.5g anti-settling agent (purchased from Degussa, R972), 0.5g thickener (purchased from Hemings Chemical), 10g titanium dioxide pigment (purchased from Ishihara Company), ultrasonically dispersed for 30 minutes to obtain component B. After mixing components A and B evenly, disperse in airtight ultrasonic for 30 minutes, cool down to room temperature after the mixture heats up, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com