Single-component polyurethane adhesive and preparation method thereof

A polyurethane adhesive, one-component technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of yellowing resistance, no toughness, poor UV resistance, etc., and prolong the service life. , to meet the water resistance, improve the effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

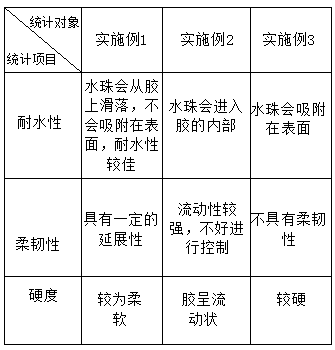

Embodiment 1

[0031] S1. Put 13 parts of hydroxy silicone oil, 15 parts of polycarbonate diol and 35 parts of trifunctional polyether polyol into the reaction stick, stir and heat up to 105°C, keep warm and vacuumize for 55 minutes, and cool down to 57°C after the moisture content is less than 0.025%. ℃, then add 7 parts of chain extender and stir evenly;

[0032] S2. After stirring evenly, add 0.0225 parts of catalyst, the above catalyst is added in 3 times, each interval is 4 minutes, while controlling the reaction temperature, the temperature is controlled at 55 ° C;

[0033] S3. Slowly drop 45 parts of HDI monomer into the reactor, control the temperature at 65°C for 45 minutes, then raise the temperature to 75°C for 45 minutes, and finally raise the temperature to 85°C After 45 minutes of reaction, after all the HDI monomers are added dropwise, control the temperature at 83°C and keep it warm for three hours;

[0034] S4. Sampling and detection-NCO content, after reaching the required...

Embodiment 2

[0037] S1. Put 10 parts of hydroxy silicone oil, 10 parts of polycarbonate diol and 30 parts of trifunctional polyether polyol into the reaction stick, stir and heat up to 100°C, keep warm and vacuumize for 50 minutes, and cool down to 55°C after the moisture is less than 0.02%. ℃, then add 5 parts of chain extender and stir evenly;

[0038] S2. After stirring evenly, add 0.015 parts of catalyst, the above catalyst is added in 3 times, each interval is 3 minutes, while controlling the reaction temperature, the temperature is controlled at 50 ° C;

[0039] S3. Slowly drop 40 parts of HDI monomer into the reactor, control the temperature at 60°C and react for 45 minutes. After all the HDI monomers are added dropwise, raise the temperature to 70°C and react for 45 minutes. Finally, the temperature was raised to 80°C for 45 minutes, and the temperature was controlled at 80°C for three hours;

[0040] S4. Sampling and detection-NCO content, after reaching the required predetermine...

Embodiment 3

[0043]S1. Put 15 parts of hydroxy silicone oil, 20 parts of polycarbonate diol and 40 parts of trifunctional polyether polyol into the reaction stick, stir and heat up to 110°C, keep warm and vacuumize for 60 minutes, and cool down to 60°C after the moisture is less than 0.03%. ℃, then add 10 parts of chain extender and stir evenly;

[0044] S2. After stirring evenly, add 0.03 parts of catalyst, the above catalyst is added in 3 times, each interval is 5 minutes, and the reaction temperature is controlled at the same time, and the temperature is controlled at 60 °C;

[0045] S3. Slowly drop 50 parts of HDI monomer into the reactor, control the temperature at 70°C for 45 minutes, then raise the temperature to 80°C for 45 minutes, and finally raise the temperature to 90°C After 45 minutes of reaction, after all the HDI monomers are added dropwise, the temperature is controlled between 83-85°C and kept for three hours;

[0046] S4. Sampling and detection-NCO content, after reachi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com