Method for preparing guaiacol products by steam-assisted fixed bed pyrolysis of lignin

A technology for pyrolyzing lignin and guaiacol, which is applied in the field of steam-assisted fixed-bed pyrolysis of lignin to prepare guaiacol products, which can solve the problem of unstable product selectivity, harsh reaction conditions, and waste of phenolic components. resources and other issues, to achieve the effect of flexible equipment technology, good economy, simple process and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add deionized water in the steam generator, close the kettle lid tightly and heat up to 250°C. Weigh 50g of pine alkali lignin and add it into the fixed bed reactor, close the kettle lid tightly and raise the temperature to 325°C. Open the outlet valve of the steam generating device, pass the saturated steam through the fixed bed reactor from bottom to top, and adjust the steam flow rate to 3g / min. After reacting for 2 hours, the steam was condensed, collected and weighed, and the aqueous phase of guaiacol products was obtained after condensation. The yield of guaiacol products was 4.36wt%, and the relative content was 87.69%.

Embodiment 2

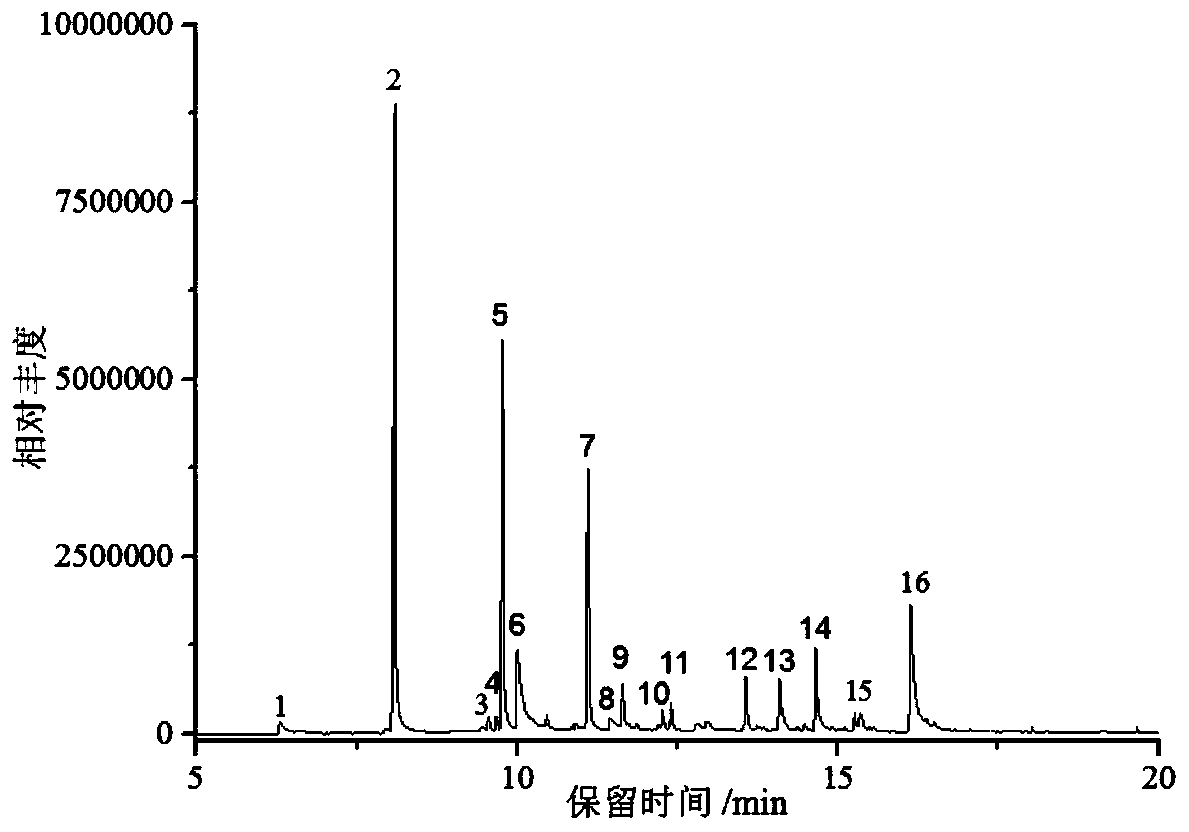

[0034] Add deionized water in the steam generator, close the kettle lid tightly and heat up to 250°C. Weigh 50g of pine alkali lignin and add it into the fixed bed reactor, close the kettle lid tightly and raise the temperature to 325°C. Open the outlet valve of the steam generating device, pass the saturated steam through the fixed-bed reactor from bottom to top, and adjust the steam flow rate to 6g / min. After reacting for 2 hours, the steam was condensed, collected and weighed, and the aqueous phase of guaiacol products was obtained after condensation. According to calculation, the yield of guaiacol products is 6.02wt%, and the relative content is 84.79%. The guaiacol products were analyzed by GC-MS total ion chromatogram, and the analysis results were as follows: figure 1 As shown, the relative content results of GC-MS components are shown in Table 1. Depend on figure 1 It can be seen from Table 1 that the components of the water phase product are all phenolic compounds...

Embodiment 3

[0039] Add deionized water in the steam generator, close the kettle lid tightly and heat up to 250°C. Weigh 50g of pine alkali lignin and add it into the fixed bed reactor, close the kettle lid tightly and raise the temperature to 325°C. Open the outlet valve of the steam generating device, pass the saturated steam through the fixed bed reactor from bottom to top, and adjust the steam flow rate to 9g / min. After reacting for 2 hours, the steam was condensed, collected and weighed, and the aqueous phase of guaiacol products was obtained after condensation. The yield of guaiacol products was 8.22wt%, and the relative content was 90.41%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com