Monitoring system and method for dynamic operation track of lifting machine

A lifting machinery, dynamic operation technology, applied in the direction of transportation and packaging, load hanging components, safety devices, etc., can solve the problems of molten iron splashed by the lifter, abnormal jumping of the crane, high damage to the track, etc., to improve the lifting capacity The effect of safe operation rate, prevention of abnormal accidents, and resolution of production safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

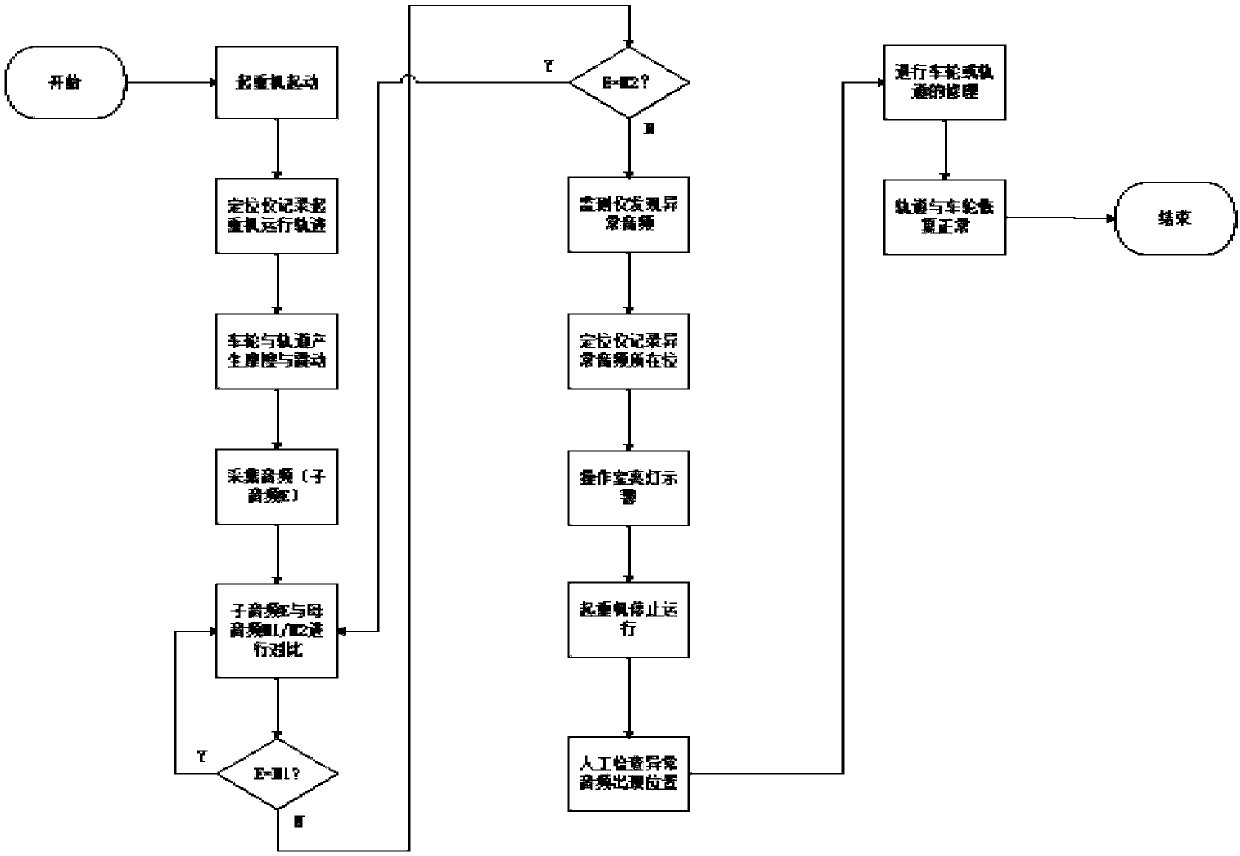

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

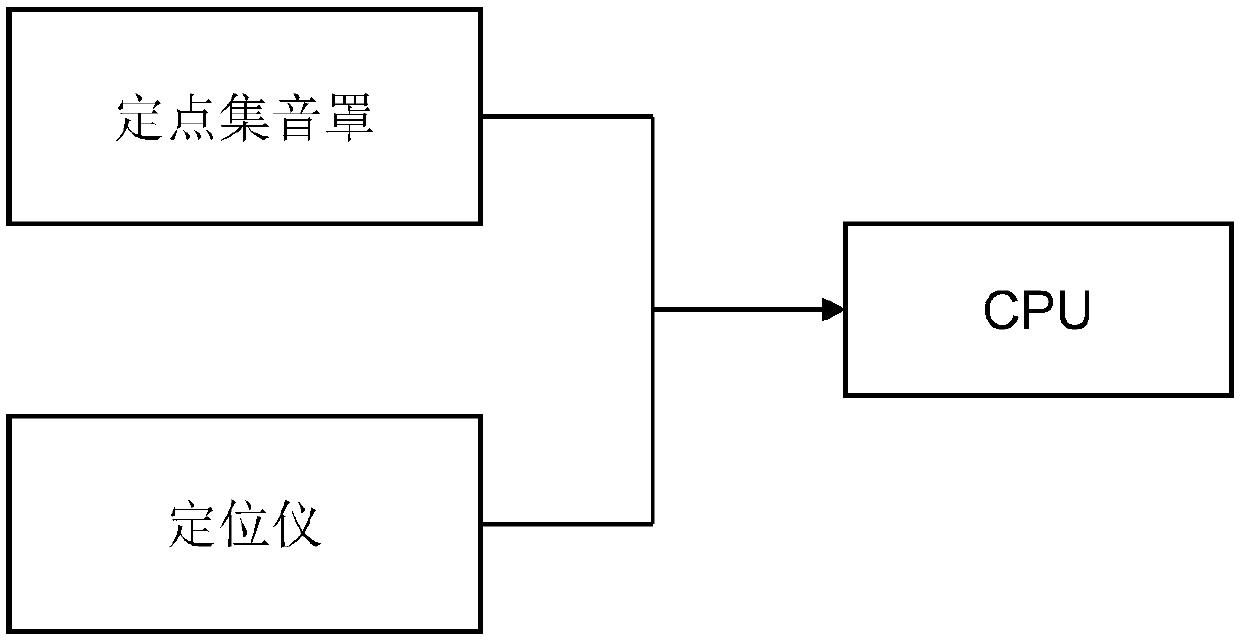

[0025] Such as figure 1 As shown, the track monitoring system of the dynamic operation of the hoisting machinery of the present invention mainly includes a fixed-point sound collecting cover, a locator and a CPU, wherein:

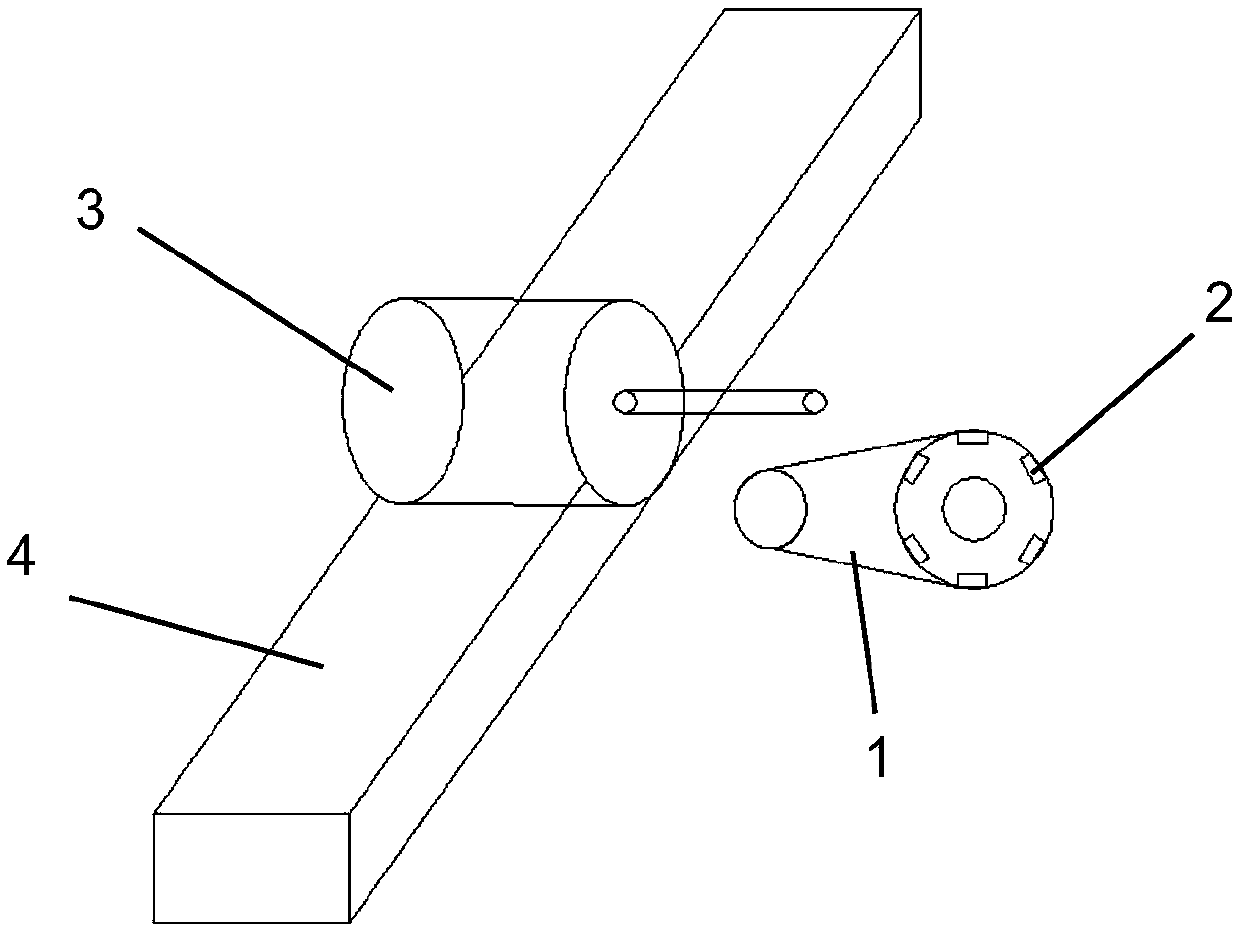

[0026] Fixed-point sound collecting cover such as figure 2 As shown, it is installed on the hoisting machinery and moves synchronously therewith, including a horn-shaped cover body 1 and several microphones 2 arranged in the cover body 1, a circuit board including an audio amplifier and a signal processing chip, and the cover body 1 The small diameter end of the hoisting machine is aligned with the joint between the wheel 3 and the track 4, and the friction sound generated by the rotating wheel 3 and the track 4 is collected at a fixed point. Installed here, it can effectively collect audio from a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com