Closed-loop cooling control system and control method for hot-rolled rods and wires after rolling

A closed-loop control, rod and wire technology, applied in temperature control and other directions, can solve the problems of lag in calculation results, poor real-time control, poor system stability, etc., to achieve the effect of good real-time performance and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

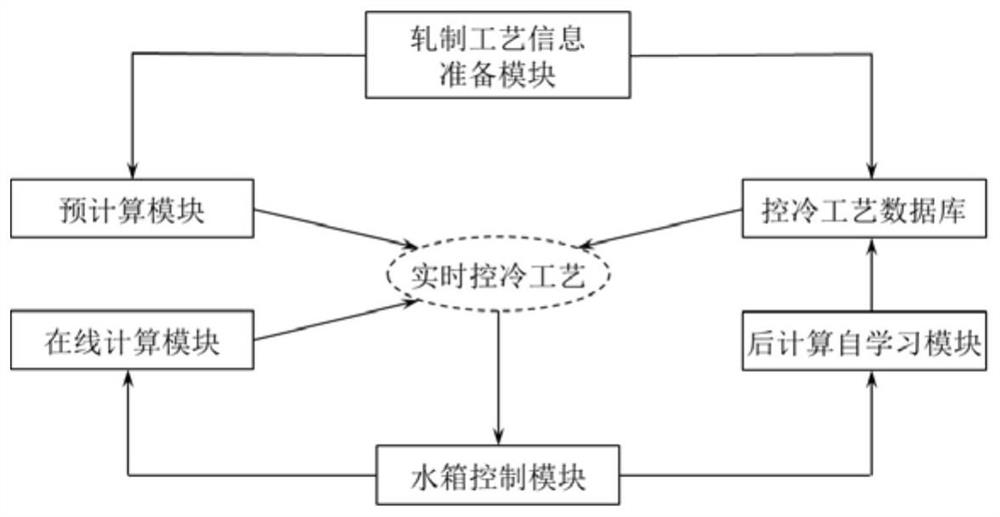

[0059] The present invention provides a closed-loop control system and control method for post-rolling cooling control of rolled pieces (threaded steel bars) with high stability, good real-time performance and strong production line applicability. The structure of the control system is as follows: figure 1 shown.

[0060] After the rolling process information preparation module acquires the initial data of the rolled piece and verifies that it is correct, it first compares it with the existing controlled cooling process parameters in the controlled cooling process database. When the controlled cooling process parameters in the controlled cooling process database match the controlled cooling process requirements of the rolled piece, the water tank control module directly calls the relevant data, and implements controlled cooling for the rolled piece passing through the water tank.

[0061] This kind of controlled cooling process parameters and system setting values stored in ...

Embodiment 2

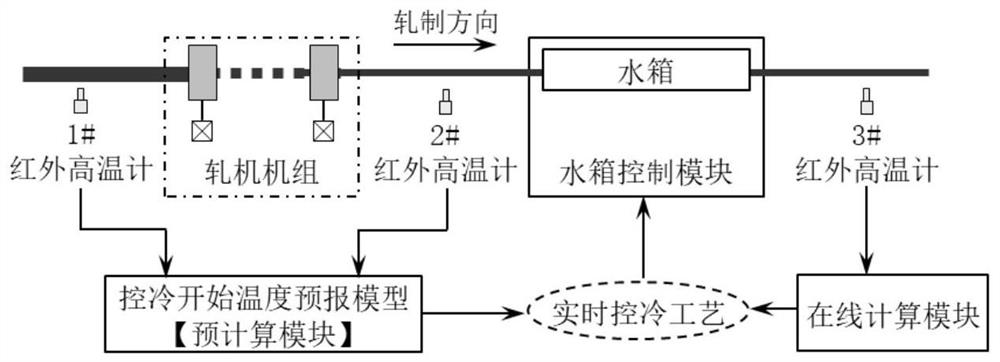

[0063] As a further solution of Embodiment 1, when none of the controlled cooling process parameters in the controlled cooling process database meet the controlled cooling process requirements of the rolled piece, the rolling process information preparation module outputs the initial data of the rolled piece to the pre-calculation module.

[0064] After the pre-calculation module receives the initial data of the rolled piece, through the calculation of each model in the module, the controlled cooling mode (water cooling, air cooling) and the controlled cooling process parameters such as the water volume and water pressure of the water tank are determined for the rolled piece that is about to enter the water tank, and the The cooling process information is sent to the water tank control module.

[0065] After the water tank control module receives the controlled cooling process parameters output by the pre-calculation module, it adjusts the water volume and water pressure of th...

Embodiment 3

[0067] As a further scheme of embodiment two, adopt figure 2 As shown in the cooling control process layout, the online calculation module monitors and receives equipment data such as the surface temperature, water flow and water pressure of the threaded steel bar measured by the 3# infrared pyrometer on the outlet side of the water tank in real time, and compares the measured value of the surface temperature of the threaded steel bar in real time and the deviation between the cooling target temperature, and when the deviation exceeds a certain range, correct the cooling process data given by the pre-calculation module, and apply the correction result to the cooling process at the appropriate position and time.

[0068] As mentioned above, the deviation between the measured value of the surface temperature of the threaded steel bar and the target temperature of the cooling control is compared, and the system responds when the deviation exceeds a certain range. The specific "r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com