Hot rolled sheet strip liquid nitrogen ultrafast cooling device

An ultra-fast cooling and hot-rolled plate technology, which is applied in workpiece cooling devices, length measuring devices, metal rolling, etc., can solve the lack of theoretical and technical research on efficient and controllable liquid nitrogen cooling equipment, limit the application field of liquid nitrogen and process development Process, control difficulty and other problems, to achieve the effect of improving cooling efficiency and cooling control accuracy, improving detection accuracy and calculation accuracy, and optimizing cooling control parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Exemplary embodiments, features, and performance aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

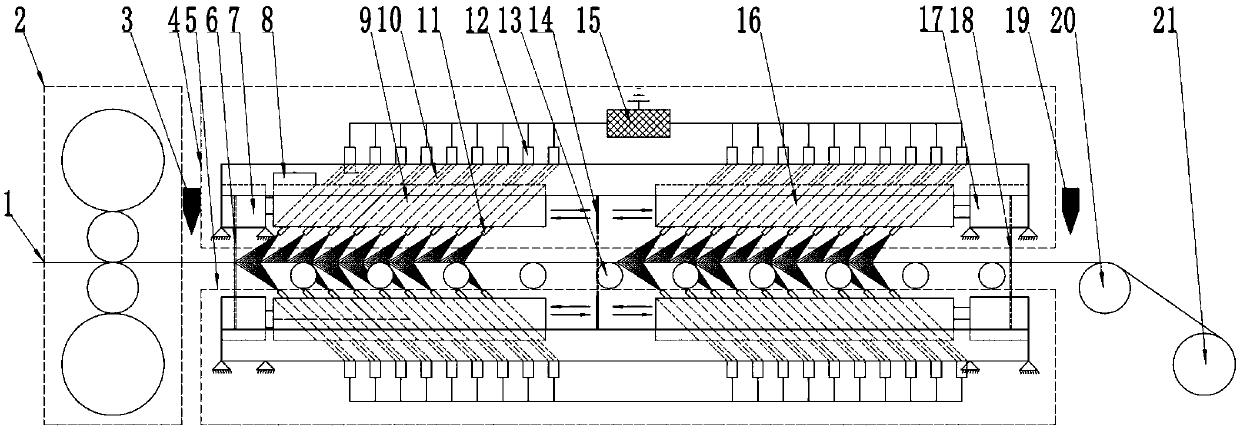

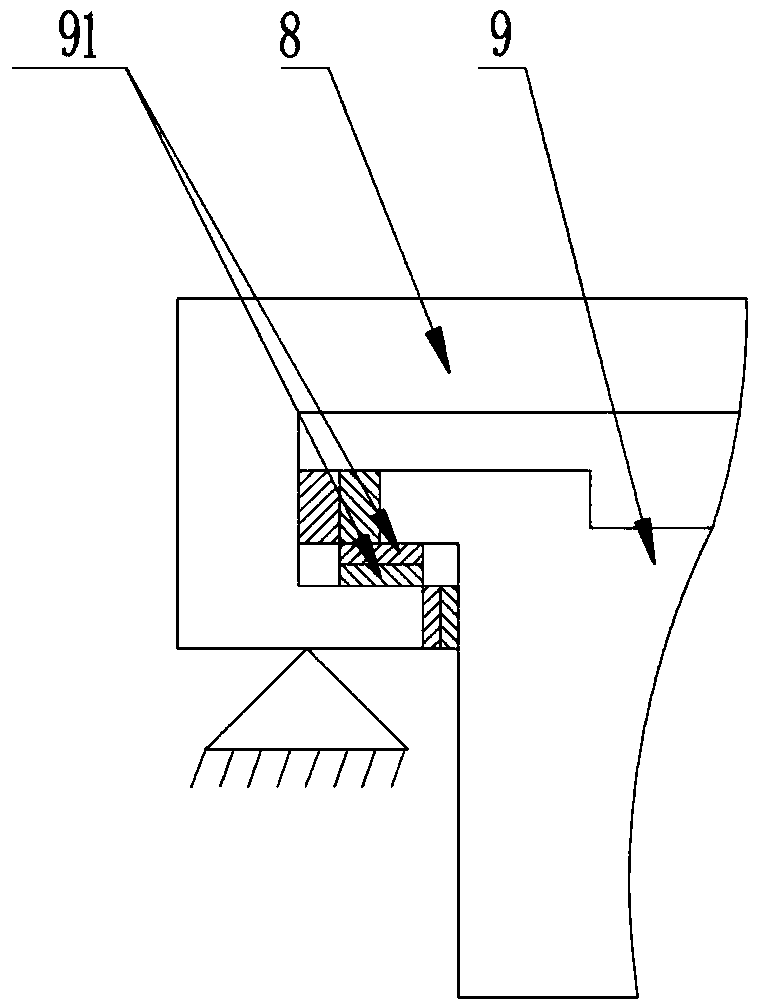

[0031] Such as figure 1 with 2Shown, a kind of hot-rolled strip liquid nitrogen ultra-quick cooling device, it comprises thermometer, controller 15 and a plurality of cold section districts, a plurality of cold section districts are located in series between finishing mill 2 and coiler, The thermometers are respectively located between the finishing mill 2 and the cold section area and between the cold section area and the coiler. The cold section area includes an upper cooling device 4 and a lower cooling device 5 symmetrically arranged on both sides of the strip. The arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com