Oil spraying and water spraying dual-purpose device for tire face of road roller tire

A technology for tire tread and dual-purpose device, which is applied to spray devices, spray devices with movable outlets, roads, etc., can solve the problems of loud construction noise, inability to control the measurement of lubrication in real time, easy oil leakage, etc., to reduce operation. Burden, improving construction efficiency and pavement quality, and preventing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

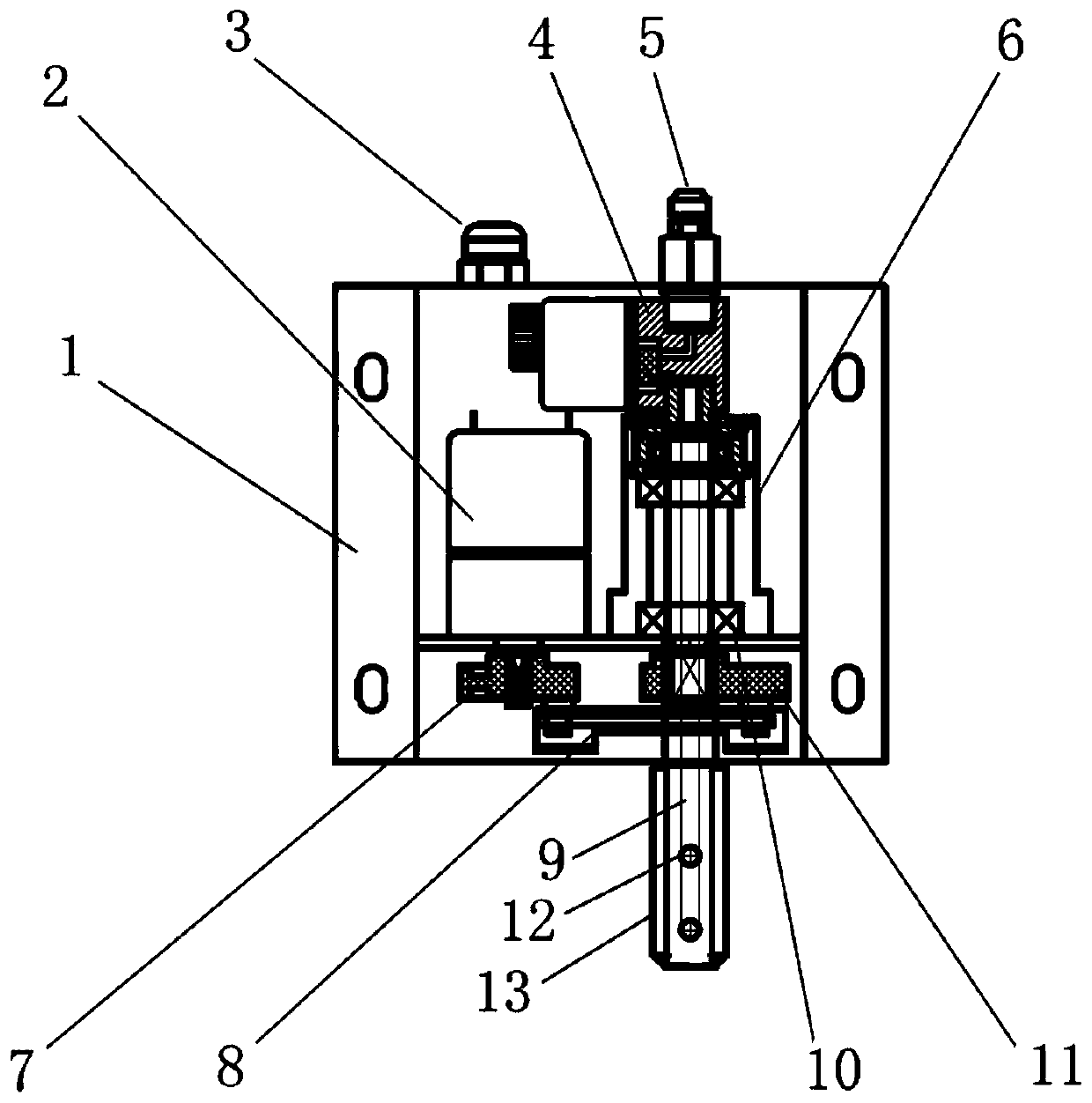

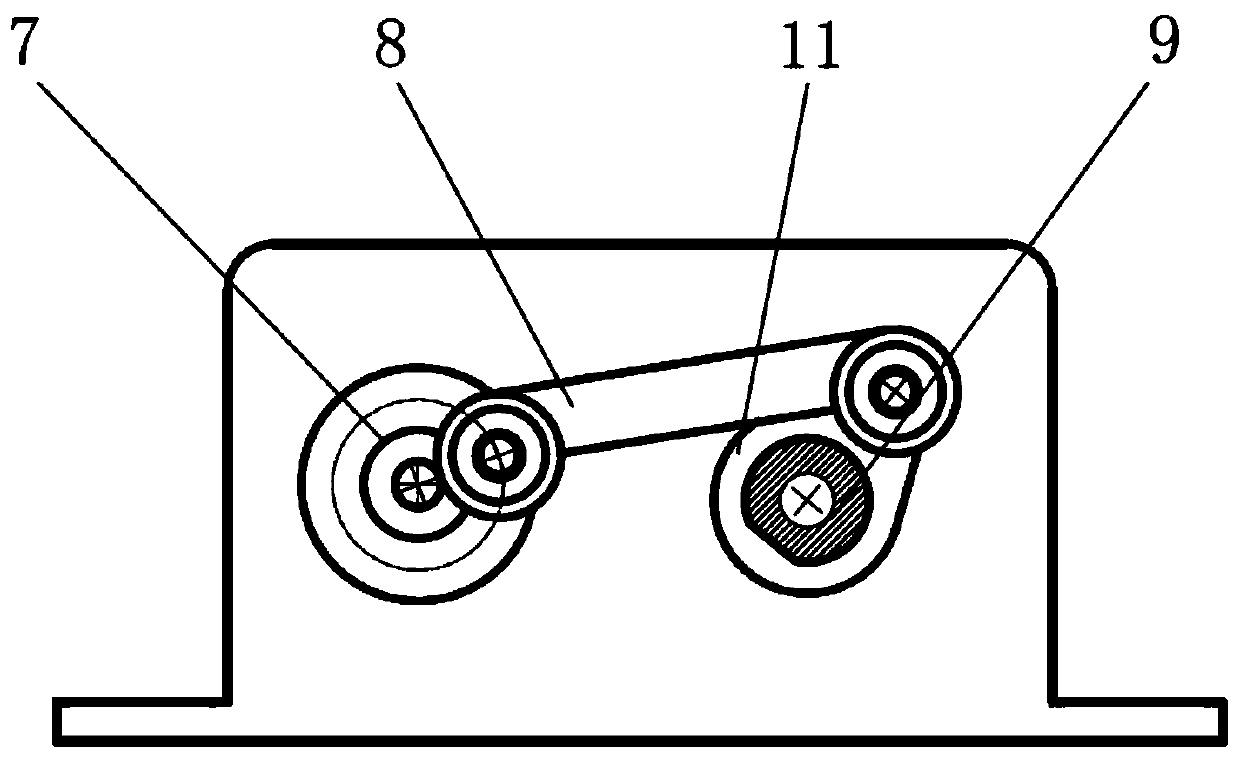

[0027] Such as figure 1 As shown, the tire tread oil / water spray dual-purpose device of a road roller includes a housing bracket 1, a two-position two-way electromagnetic reversing valve 4, a bearing assembly, an oil injection shaft 8, an eccentric wheel 7, a connecting rod 8, and a rocker 11. Gear motor 2. Oil supply device and control device (the control device can adopt industrial control switch, PLC or single-chip microcomputer, such as STM32, etc.). There are outlet holes 3 and oil inlet joints 5 on the edge of the housing bracket 1 and a protective cover 13 is installed. The geared motor 2, the two-position two-way electromagnetic reversing valve 4 and the data input end of the oil supply device are respectively connected to the control device through signal lines, and the signal lines connected to the geared motor 2 and the two-position two-way electromagnetic directional valve 4 are connected by The hole 3 extends out of the housing bracket 1, and the geared motor 2 i...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the controller is a remote control device, the remote control device includes a remote control switch and a remote control, the remote control switch includes a receiving module and several relays, the receiving module and the relay are located on the same PCB, two-position The electromagnetic reversing valve 4, the reduction motor 2, and the DC motor are respectively connected with the relay, and the signal frequency of the remote controller is 315MHz or 433MHz.

[0033] When fuel injection is required, within an appropriate distance, press the start button on the remote controller, and the remote control switch will simultaneously open the two-way electromagnetic reversing valve 4, the reduction motor 2 and the DC motor, and the fuel injection device will start to inject fuel. When oiling, press the stop key on the remote controller, the remote control switch synchronously closes the two-way electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com