Porous flaky molybdenum phosphide/carbon composite material and preparation method thereof

A composite material, molybdenum phosphide technology, applied in the field of material processing, can solve the problem of low hydrogen evolution catalytic activity, and achieve the effects of high purity, low production cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

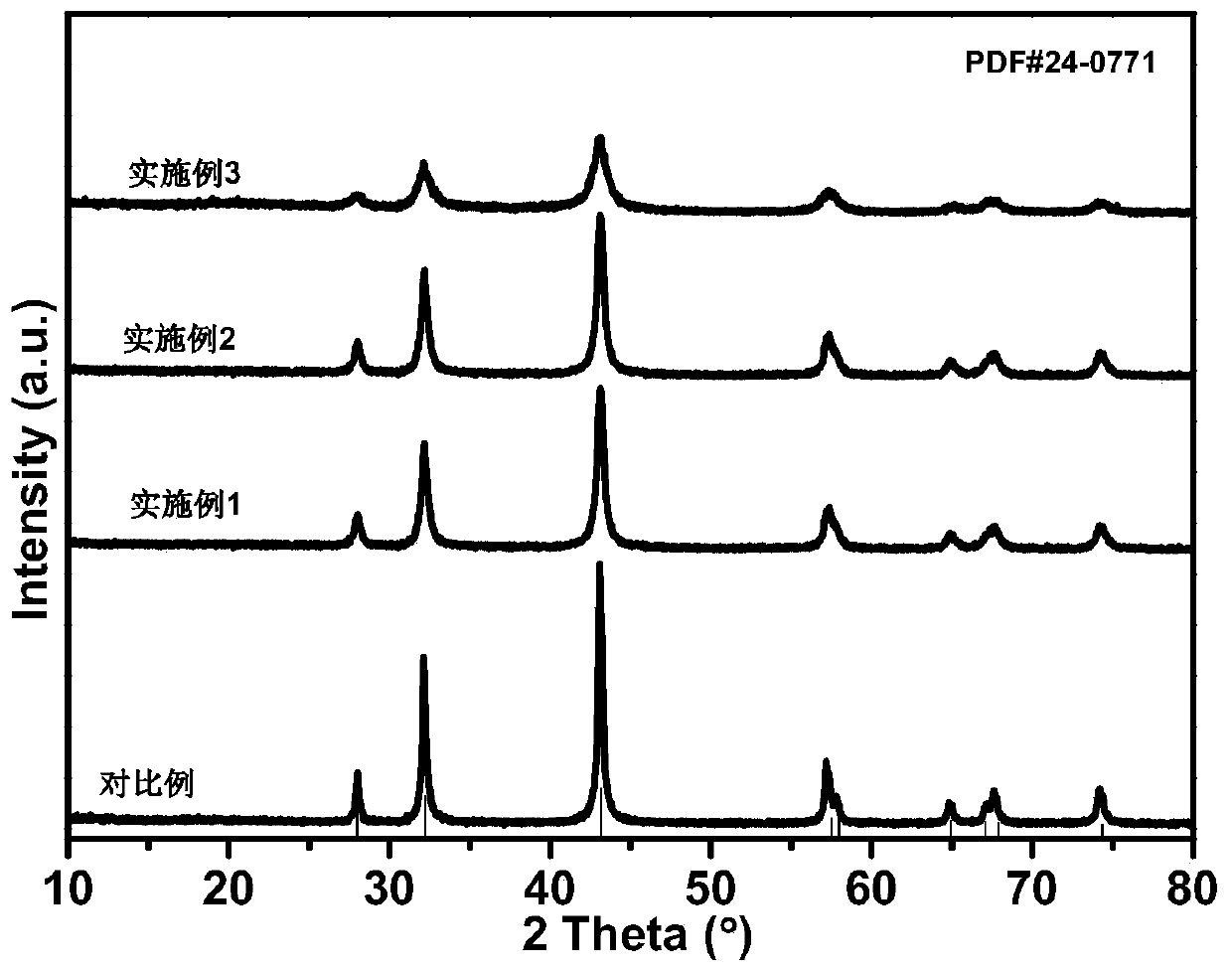

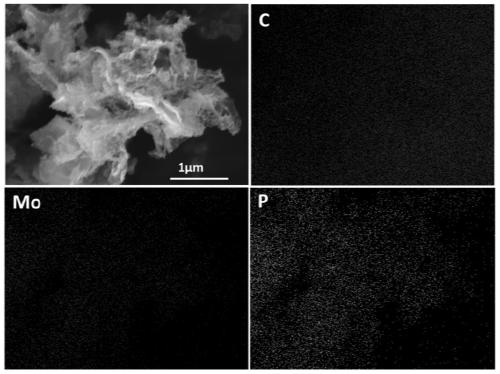

Examples

preparation example Construction

[0024] On the one hand, an embodiment of the present invention provides a method for preparing a porous sheet-like molybdenum phosphide / carbon composite material, comprising the following steps:

[0025] S01: Provide molybdenum source, phosphorus source, carbon source and sodium chloride;

[0026] S02: dissolving the molybdenum source, phosphorus source, carbon source and sodium chloride in an aqueous solvent to obtain a mixed solution;

[0027] S03: drying the mixed solution to obtain a precursor powder;

[0028] S04: Calcining the precursor powder and then cleaning it to obtain a porous flake molybdenum phosphide / carbon composite material.

[0029] The preparation method of the porous flake molybdenum phosphide / carbon composite material provided by the embodiment of the present invention uses molybdenum source, phosphorus source, carbon source and sodium chloride as raw materials, dissolves it in a water solvent to obtain a mixed solution, and passes through Drying treatme...

Embodiment 1

[0043] A kind of preparation method of porous flake molybdenum phosphide / carbon composite material, comprises the following steps:

[0044] (1). Dissolve 100 mg ammonium molybdate tetrahydrate, 100 mg ammonium dihydrogen phosphate, and 1000 mg dicyandiamide in 50 mL deionized water, stir and ultrasonically dissolve until completely dissolved, and continue stirring for about 30 minutes to obtain the first mixed solution;

[0045] (2). Add 3000 mg of sodium chloride to the solution obtained in step (1), stir until completely dissolved, and continue stirring for 3 hours to obtain the second mixed solution;

[0046] (3). Put the second mixed solution into a refrigerator freezer at -30°C and freeze for 24 hours, then place the frozen product in a vacuum freeze dryer, and freeze-dry for 72 hours to obtain a dry solid powder. Grind for 10 minute;

[0047] (4). The dried precursor was calcined in a nitrogen atmosphere at a heating rate of 5°C / min, raised to 900°C, and calcined at a c...

Embodiment 2

[0050] A kind of preparation method of porous flake molybdenum phosphide / carbon composite material, comprises the following steps:

[0051] (1). Dissolve 100 mg ammonium molybdate tetrahydrate, 100 mg ammonium dihydrogen phosphate, and 1000 mg dicyandiamide in 50 mL deionized water, stir and ultrasonically dissolve until completely dissolved, and continue stirring for about 30 minutes to obtain the first mixed solution;

[0052] (2). Add 1000 mg of sodium chloride to the solution obtained in step (1), stir until completely dissolved, and continue stirring for 3 hours to obtain the second mixed solution;

[0053] (3). Put the second mixed solution into a refrigerator freezer at -30°C and freeze for 24 hours, then place the frozen product in a vacuum freeze dryer, and freeze-dry for 72 hours to obtain a dry solid powder. Grind for 10 minute;

[0054] (4). The dried precursor was calcined in a nitrogen atmosphere at a heating rate of 5°C / min, raised to 900°C, and calcined at a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com