Super(sub)critical CO2 scouring device

A CO2 and wool scouring technology, which is applied in the recovery/refining of fatty substances, chemical post-treatment of fibers, animal raw materials, etc., can solve the problems of difficult extraction of organic pollutants, high water consumption and energy consumption, high oil, high pollution, etc., to achieve The effect of solving high water consumption and high pollution problems, efficient recycling, and meeting the requirements of clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

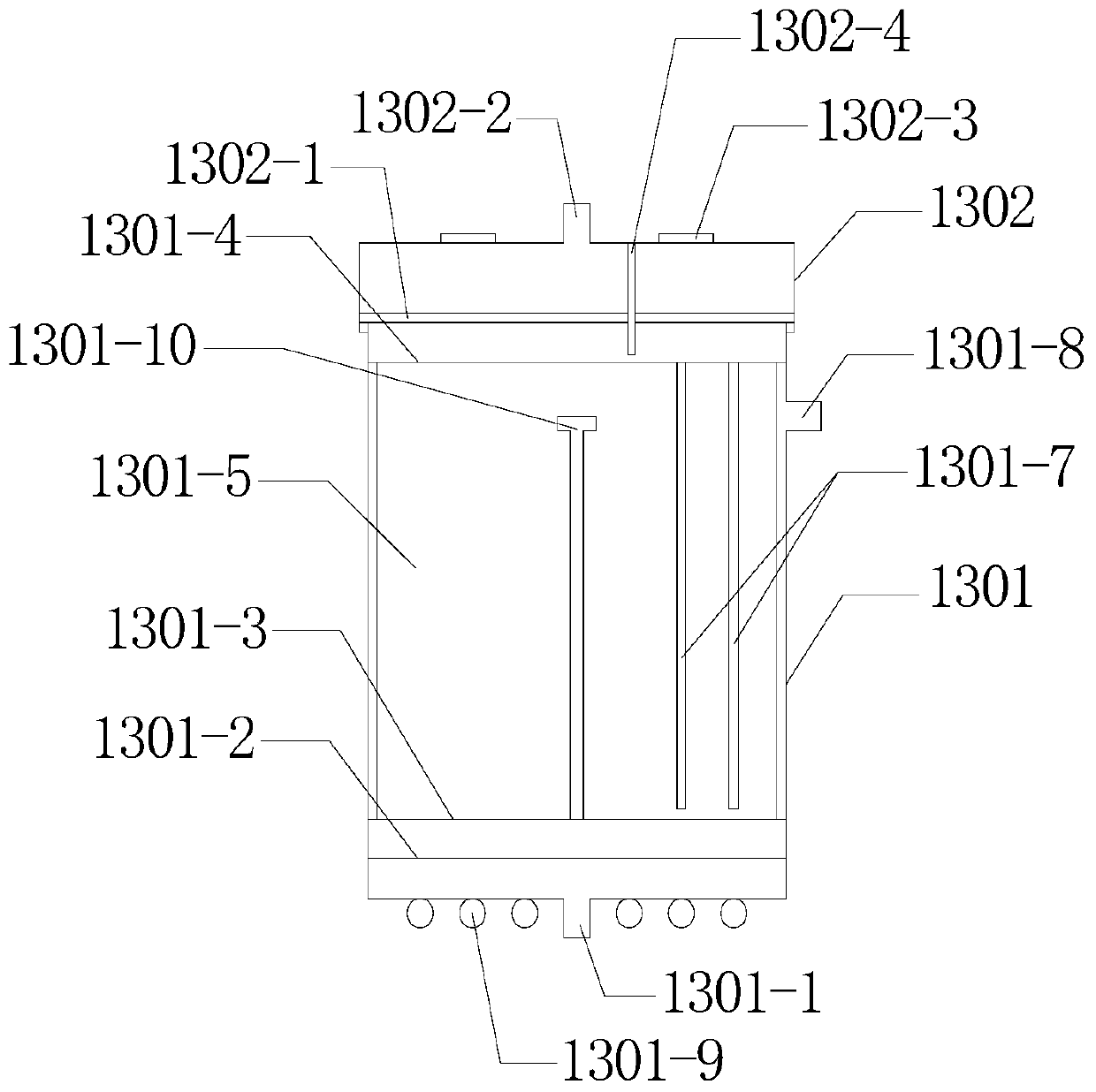

[0025] A super(sub)critical CO 2 Scrubbing kettle, the super(sub)critical CO 2 The scouring kettle includes a kettle body 1301 of the scouring kettle and a lid 1302 of the scouring kettle;

[0026] The bottom of the kettle body 1301 is provided with CO 2 Inlet 1301-1 and several ultrasonic transducers 1301-9;

[0027] A water impurity separation membrane 1301-2 with a pore size of 0.5 μm is installed inside the kettle body 1301, and a water enrichment zone is formed between the water impurity separation membrane 1301-2 and the bottom of the kettle body 1301;

[0028] The kettle body 1301 is provided with a porous bottom plate 1301-3 with a pore diameter of 0.5mm, and the porous bottom plate 1301-3 is located above the water-impurity separation membrane 1301-2, and the porous bottom plate 1301-3 and the water-impurity separation membrane An impurity-enriched area is formed between 1301-2;

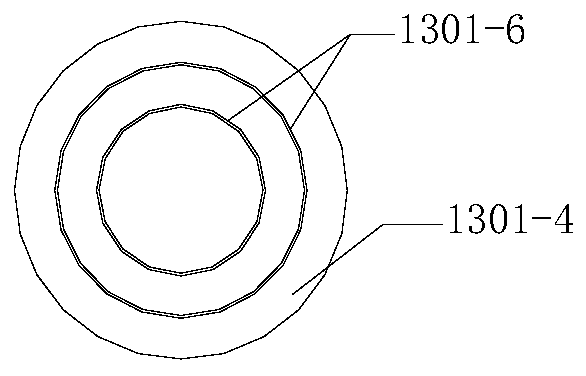

[0029] The kettle body 1301 is provided with a porous cover plate 1301-4 with a pore...

Embodiment 2

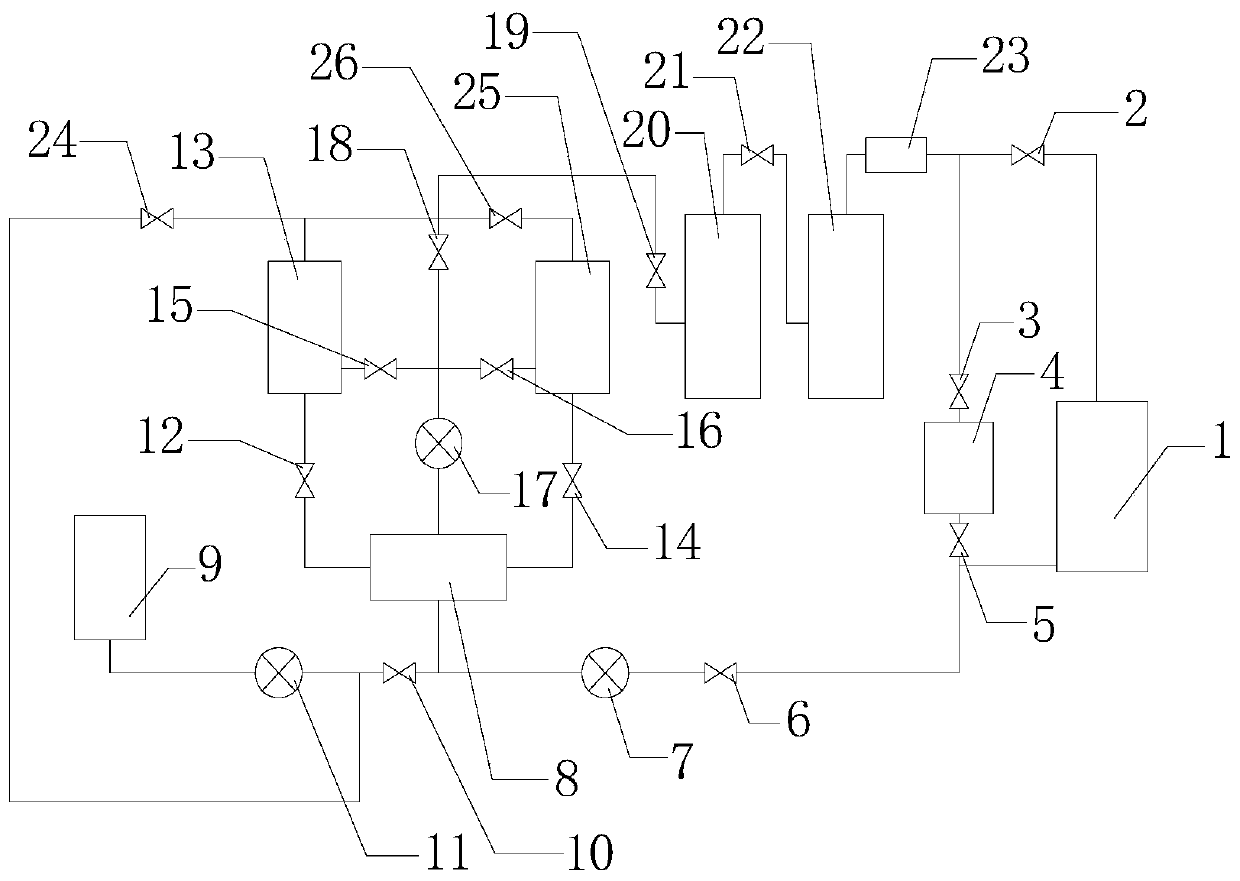

[0038] A super(sub)critical CO 2 Wool washing device, the super(sub)critical CO 2 The washing unit includes CO 2 Liquid storage tank 1, condenser 4, CO 2 Booster pump 7, heat exchanger 8, solvent storage tank 9, metering pump 11, super (sub) critical CO described in embodiment 1 2 Washing kettle Ⅰ13, and super (sub)critical CO 2 The same super (sub) critical CO as the washing kettle Ⅰ13 2 Washing kettle Ⅱ 25, CO 2 Circulation pump 17, separation kettle I20, separation kettle II22, adsorber 23;

[0039] The CO 2 The outlet Ⅰ of the liquid storage tank 1 passes through valve Ⅰ2, valve Ⅱ3, condenser 4, valve Ⅲ5, valve Ⅳ6, CO 2 The booster pump 7 is connected to the inlet I of the heat exchanger 8;

[0040] The solvent storage tank 9 is sequentially connected to the inlet I of the heat exchanger 8 through the metering pump 11 and the valve V10;

[0041] The outlet I of the heat exchanger 8 passes through the valve VI12 and the super (sub) critical CO 2 CO in scouring ket...

Embodiment 3

[0054] Utilize the super(sub)critical CO of the device described in embodiment 2 2 A method for scouring hair, said method comprising the steps of:

[0055] Firstly, the wool (velvet) fibers after the initial opening are transported to the super (sub) critical CO 2 Wool (velvet) bin 1301-5 and super (sub) critical CO 2 In the wool (velvet) bin of scouring kettle II 25, the super (sub)critical CO 2 Wool (velvet) bin 1301-5 and super (sub) critical CO 2 The hair (velvet) bins of the hair scourer II 25 are put into super (sub) critical CO 2 Kettle body 1301 and super(sub)critical CO of hair washing kettle I13 2 In the kettle body of scouring kettle II 25, close the super (sub)critical CO 2 Kettle cover 1302 of hair washing kettle I13, super (sub)critical CO 2 The lid of the washing kettle II 25;

[0056] Liquid CO 2 transported to CO 2 In the liquid storage tank 1, the co-solvent is delivered to the solvent storage tank 9;

[0057] When scouring wool, first open valve I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com